How to choose the right laser pipe cutting machine?

In the field of pipe processing, having a suitable laser Pipe Cutting machine is of vital importance. So, how can one select the equipment that meets their own needs?

NO.1 Clarify the requirements

Types of processed pipes

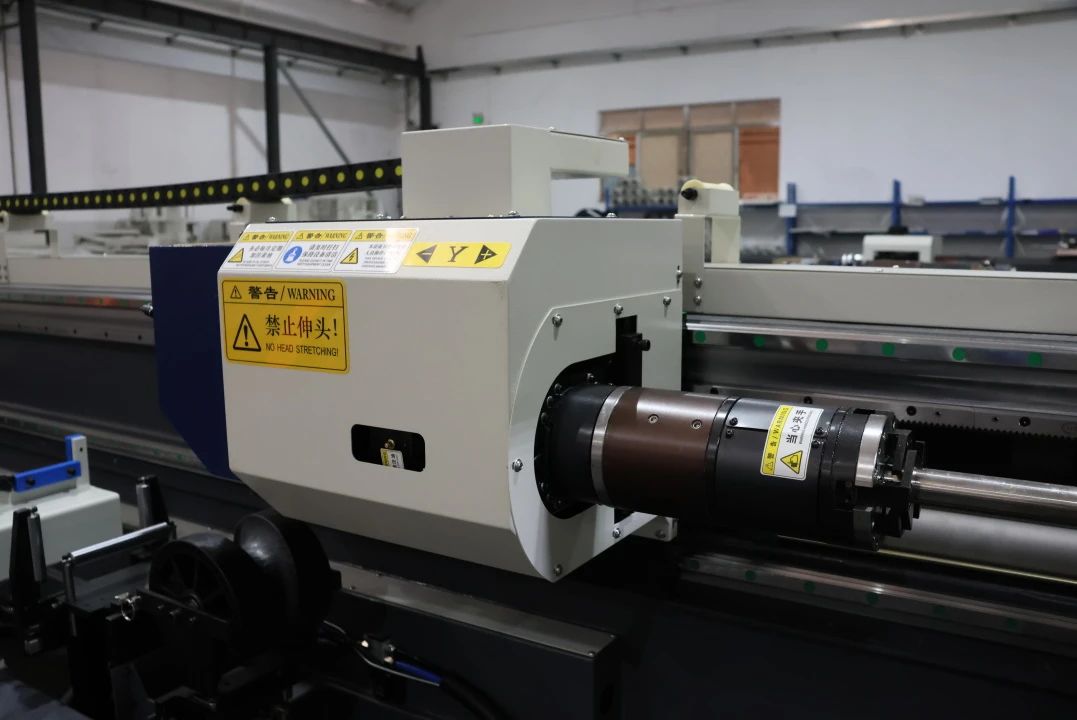

Determine the material of the pipe to be cut, such as carbon steel, stainless steel, aluminum alloy, etc. Different materials have different absorption and reflection characteristics of laser, and thus require laser pipe cutting machines of different powers. At the same time, the shape of the pipe should be taken into consideration, including round, square, rectangular and special-shaped pipes, etc., to ensure that the machine can adapt to the processing requirements of various shapes.

Pipe size

Measure the dimensional range such as the diameter, wall thickness and length of the pipe. Larger-sized pipes require laser pipe cutting machines with greater power and working range, while smaller-sized pipes can choose more compact and flexible equipment.

Requirements for cutting accuracy

If high cutting accuracy is required, such as in the manufacturing of precision instruments or high-end decoration fields, a laser pipe cutting machine with high precision and good stability needs to be selected. Generally speaking, the positioning accuracy of the equipment, the repeat positioning accuracy, and the flatness of the cutting edge are all important indicators for measuring the cutting accuracy.

NO.2 Examine the performance of the equipment

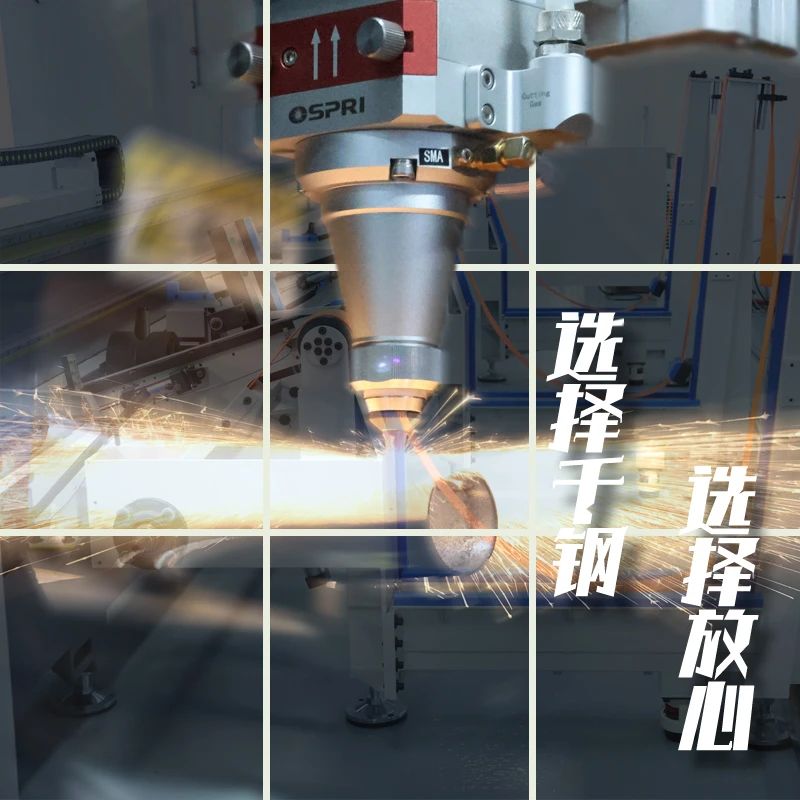

01 Laser Power

Laser power directly affects the cutting speed and thickness. High-power laser pipe cutting machines can cut thicker pipes and have a faster cutting speed. However, the higher the power, the higher the price of the equipment, and at the same time, the energy consumption will also increase. Therefore, the appropriate laser power needs to be selected based on the actual processing requirements.

02 Cutting Speed

Cutting speed is an important indicator for measuring the efficiency of laser pipe cutting machines. Generally speaking, the faster the cutting speed, the higher the production efficiency. However, the cutting speed is also affected by factors such as laser power, pipe material, thickness and cutting accuracy. When choosing equipment, you can refer to the technical parameters provided by the manufacturer and actually observe the cutting demonstration of the equipment to understand its cutting speed under different conditions.

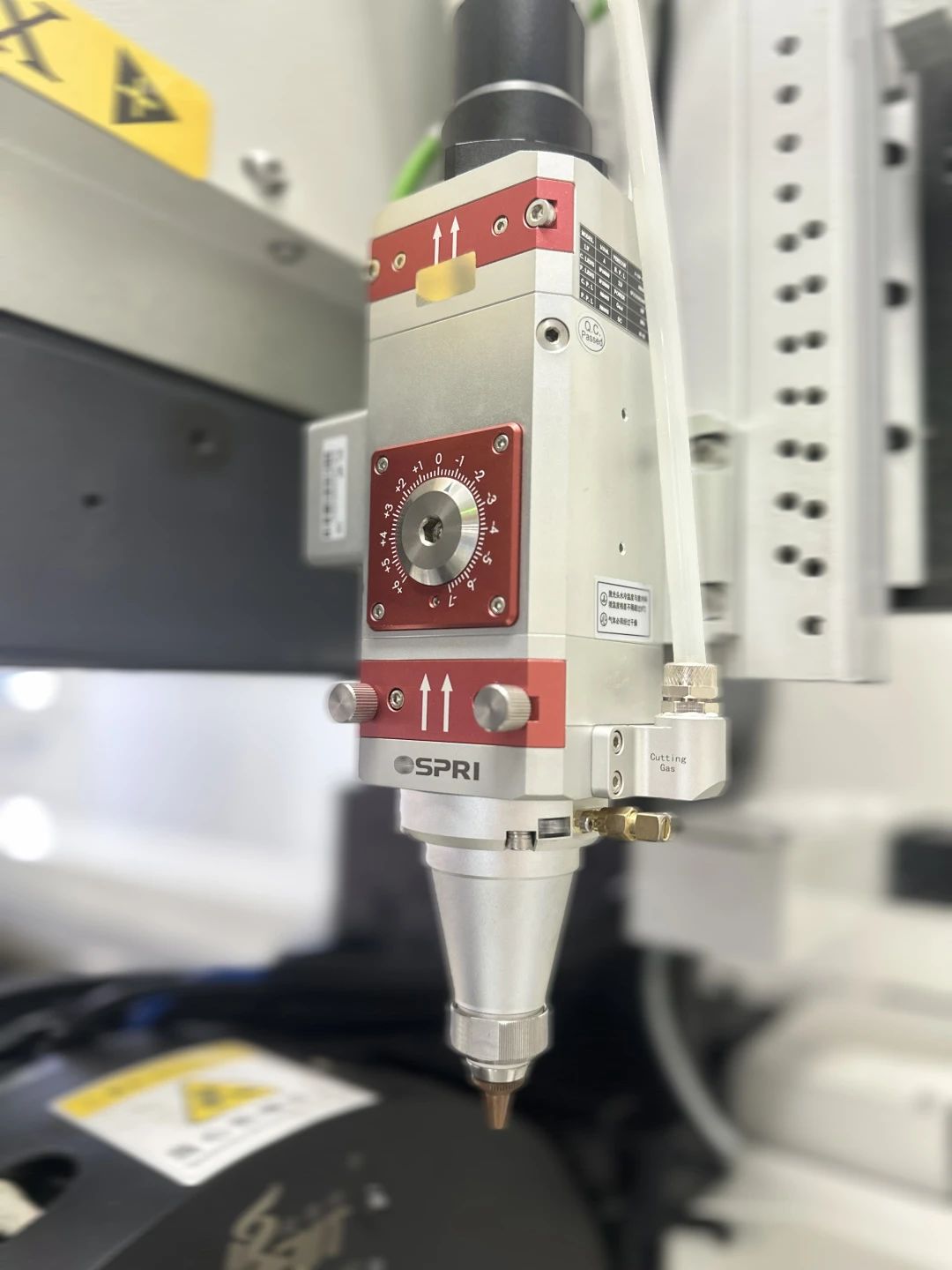

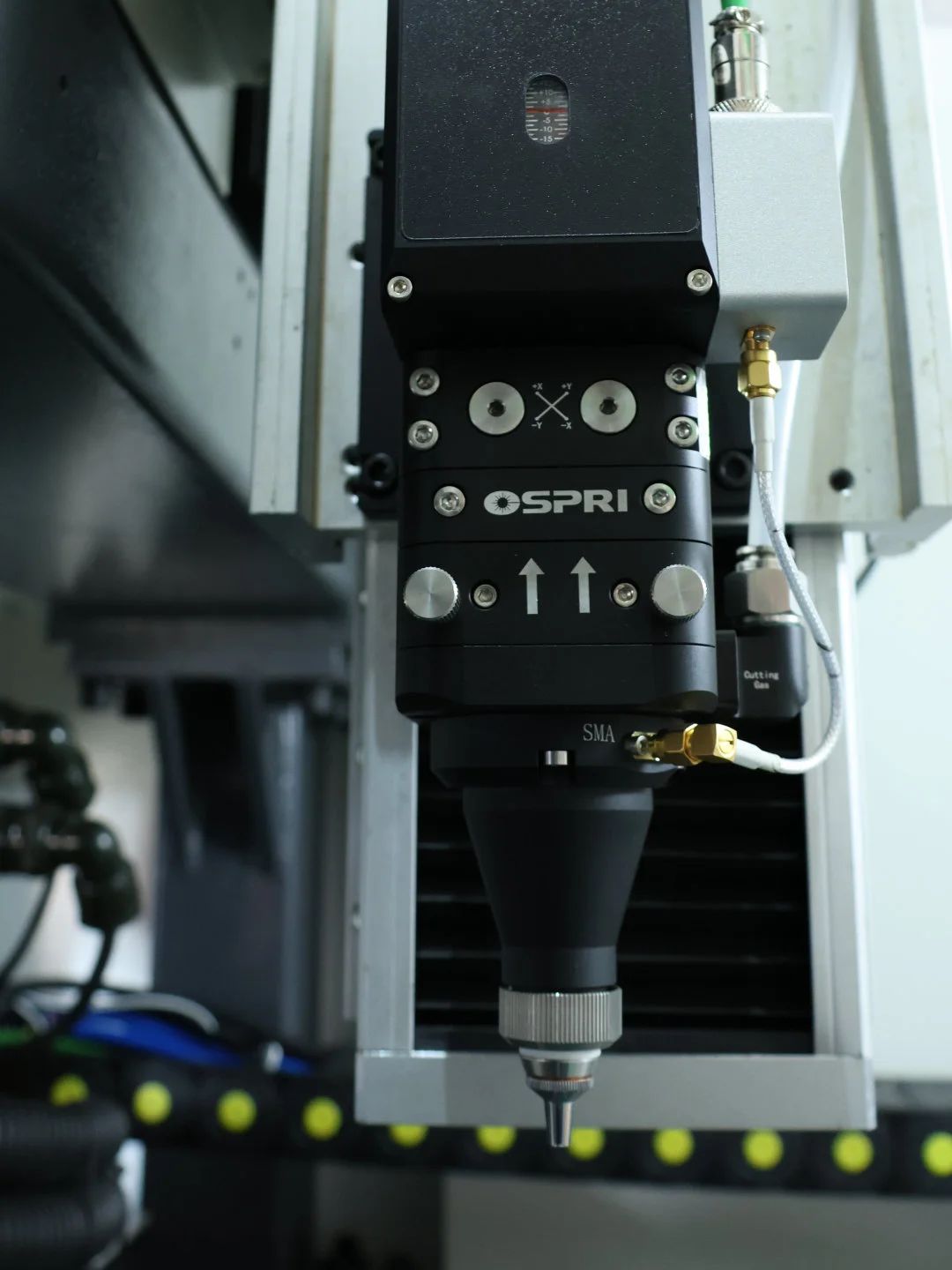

03 Precision and Stability

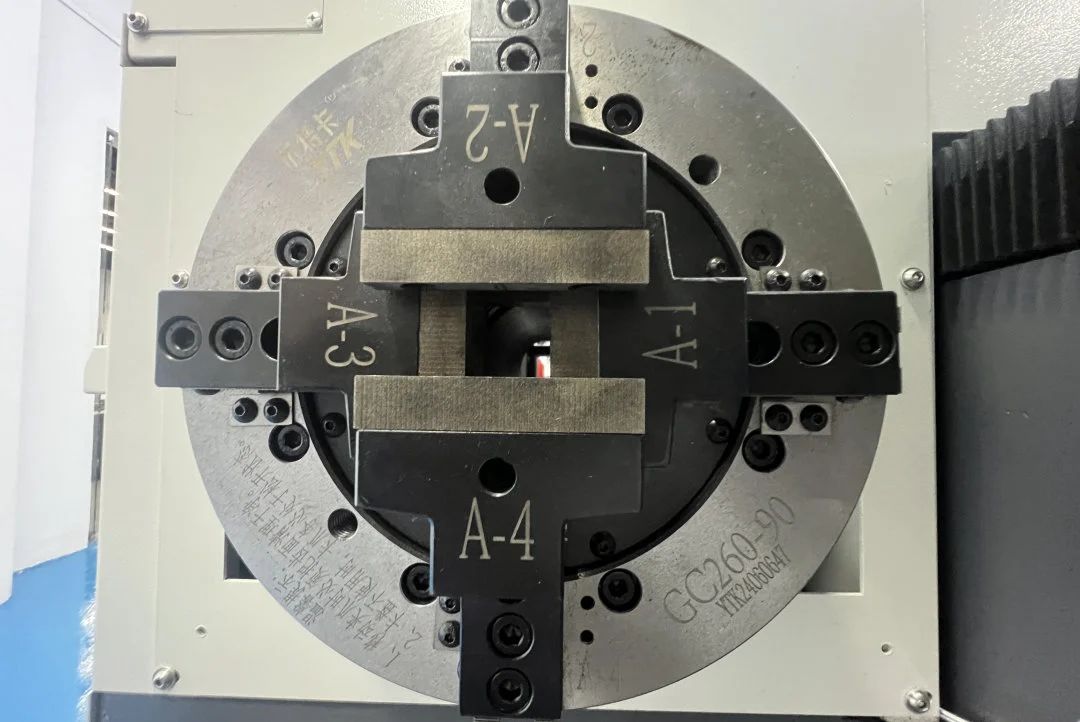

Accuracy includes cutting dimensional accuracy and shape accuracy. Stability refers to the ability of the equipment to maintain cutting accuracy during long-term operation. The accuracy and stability of the equipment can be evaluated by examining aspects such as its structural design, transmission system, and control system. For instance, the adoption of high-precision guide rails, lead screws and servo motors, as well as advanced control systems, can enhance the accuracy and stability of the equipment.

04 Degree of Automation

Laser pipe cutting machines with a high degree of automation can reduce manual operations, improve production efficiency and quality. For instance, automatic feeding and discharging systems, automatic positioning systems, as well as the integration capabilities with other automated equipment, are all important indicators for measuring the degree of equipment automation

NO.3 Focus on the brand and after-sales service

Brand reputation

Choosing a laser pipe cutting machine from a well-known brand can ensure the quality and performance of the equipment. Well-known brands usually have richer R&D experience, more advanced technologies and more complete after-sales service systems. One can learn about the reputation and credibility of different brands by consulting industry materials, inquiring with peer users, and participating in exhibitions.

After-sales service

After-sales service is a factor that cannot be ignored when choosing a laser pipe cutting machine. Good after-sales service can ensure the normal operation of equipment, reduce downtime and improve production efficiency. When choosing equipment, it is necessary to understand the after-sales service content of the manufacturer, including the warranty period, maintenance response time, technical support and other aspects.

Choosing the right laser pipe cutting machine requires a comprehensive consideration of multiple aspects such as cutting accuracy, speed, stability, after-sales service and price. Only in this way can the laser pipe cutting machine become your capable assistant in production and help the enterprise develop efficiently. If you still have any questions about the selection of laser pipe cutting machines, please feel free to consult us at any time. We will serve you wholeheartedly.

Contact us

Our address and contact details

Address:Workshop No.2., Longzhen Road, Xincheng Industrial Zone, Shapu Village Committee, Jun’an Town, Shunde District, Foshan City, Guangdong Province(Laser machine Production base)

Contact Mobile: +8619886141247

Website: http://www.qglasermachine.com

Long Press Recognition

Follow Our Official Account

Long Press Recognition

Add WhatApp to Know More

Long Press Recognition

Add WeChat to Know More