High-speed 3D Five-axis Bevel Laser pipe Cutting Machine

Product Detail

Product introduction

Features

Application

Parameters

|

Model |

G170K |

|

Laser Power (W) |

1500/2000/3000 |

|

Cutting range (MM) |

Circumference:10-170 |

|

Repeat positioning accuracy (MM) |

±0.02 |

|

Pipe length range(MM ) |

≈6250 |

|

Machine size (MM) |

L*W*H:8874*1720*2175 |

|

Body + Rack size (MM) |

semi-Automatic(L*W*H):8874*2170*2175 |

|

Machine weight(kg) |

≈3 |

|

Acceleration(G) |

≈1.3 |

|

Tailings length(MM) |

≈80 |

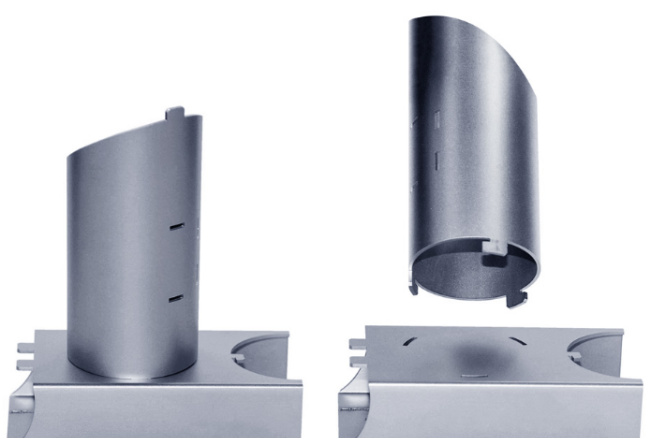

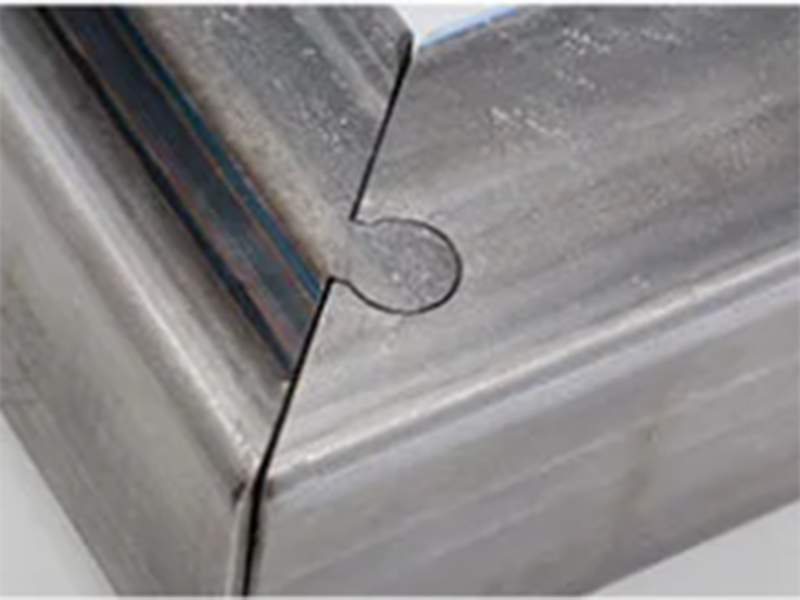

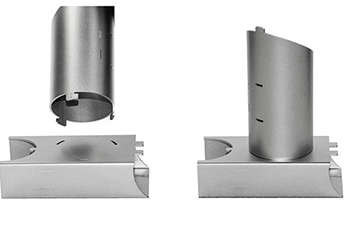

Samples

Structures

-

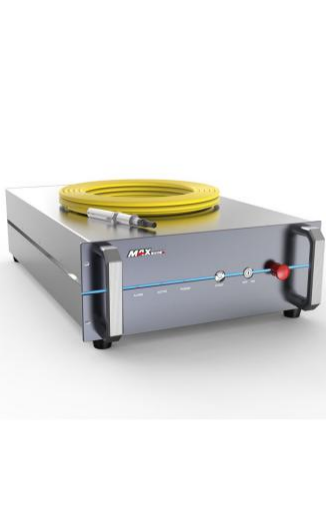

1.Laser source: Max/Raycus

-

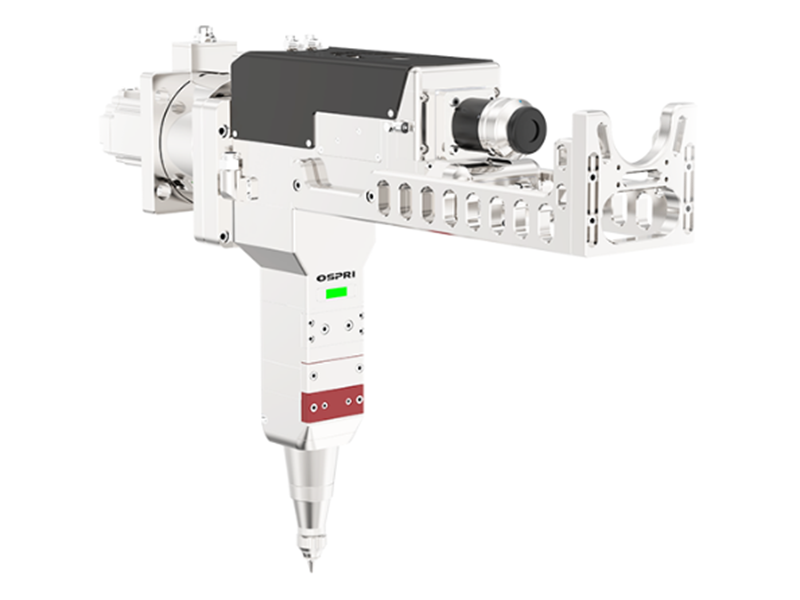

2.Laser cutting head: Ospri

2.Laser cutting head: Ospri -

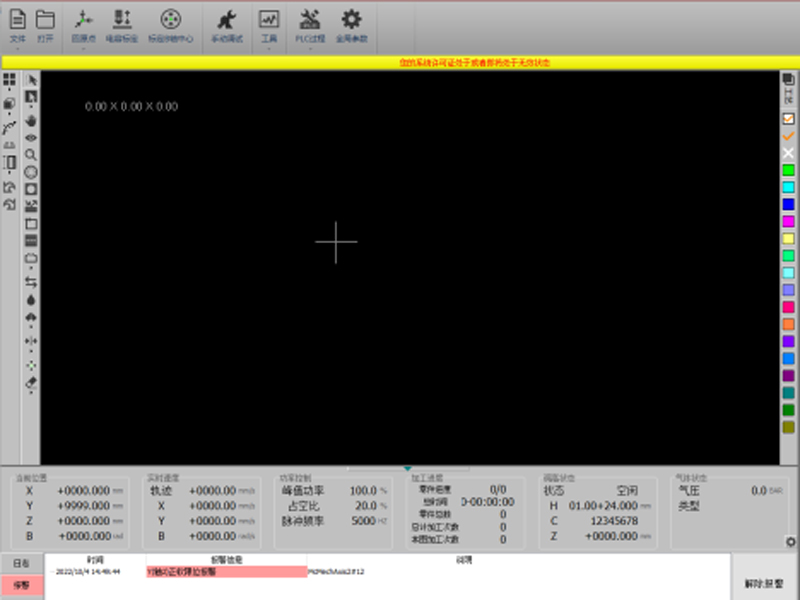

3.Operating system: Bochu FSCUT3000

-

4.Servo motors: Huichuan/Delta

5. Water chiller: Hanli

Details

|

G170K semi-automatic Laser pipe Cutting Machine Equipment parameter |

|

|

Parameter |

Supplier |

|

Laser source |

Raycus / Max |

|

Laser head |

Ospri |

|

Water cooling unit |

Hanli |

|

Chuck |

Beut Precision / Taiyuan Precision |

|

Servo motor |

Huichuan |

|

Guide rail slider |

Taiwan TBI |

|

Pipe processing range |

10-170 MM |

|

Configuration of material rack |

Optional receiving rack (2 pneumatic supports as standard) |

|

Minimal cutting length |

1mm |

|

Loading length |

Automatic : 6000- 6250mm |

|

Thickness of cutting material |

Depending on laser power (8.0mm thickness per 3000W) |

|

Cutting slit width |

0.1-0.15mm |

|

Machine tool repeated positioning accuracy |

±0.02mm |

|

Maximal acceleration |

1.3G |

|

Voltage |

380V/50Hz/60Hz |

|

Total weight of equipment |

About 3 tons |

|

Equipment dimension |

Length8874*width 1720*height2175mm |