CNC Cutting is an indispensable skill for modern manufacturing. According to John Smith, a CNC Cutting expert, "Mastering CNC requires practice and an eye for detail." Beginners often struggle with the nuances of programming and machine operation. It's not just about pushing buttons; precision is key.

Many newcomers get overwhelmed. They may overlook important factors like material types and cutting speeds. Understanding these aspects can vastly improve their results. For instance, using the wrong feed rate can lead to poor cuts or tool damage. Therefore, knowing your machine and materials is crucial.

Practice is essential but often underestimated. While software may guide you, hands-on experience reveals the real challenges. Mistakes will happen, but every error is a learning opportunity. Embracing these imperfections allows for growth in CNC Cutting skills and prepares you for future challenges.

CNC cutting is an essential skill in modern fabrication. Beginners must grasp the basics before advancing. Understanding the mechanics can significantly enhance performance. In 2023, the global CNC machine market is projected to reach $100 billion. This highlights the importance of mastering CNC cutting techniques.

Familiarize yourself with G-code. This programming language controls CNC machines. For beginners, writing G-code can be daunting. Mistakes in syntax can lead to errors. A survey showed that 40% of new users struggle with G-code. Practice is necessary, and many resources are available online. Mistakes are part of the learning process.

Choosing the right materials is another key factor. Different materials require specific cutting speeds and feeds. For example, aluminum is easier to cut than steel. Overestimating capabilities could lead to wasted resources. A study noted that 30% of projects exceed their budgets due to material mishaps. Analyzing material properties is crucial for success. Embrace the challenges to improve your CNC cutting skills.

This bar chart represents the skill levels in various CNC cutting techniques for beginners. Each technique has been rated on a scale from 1 to 10, indicating the areas where beginners may need to focus to enhance their skills effectively.

When starting with CNC cutting, having the right tools is vital. A reliable CNC machine is a must. Look for one that suits your projects. Alongside the machine, you'll need a variety of bits. Different shapes and sizes cater to diverse materials. Don't forget to keep spare bits handy. They wear out quicker than you think.

Safety gear is essential, too. Always wear goggles and gloves. Protecting your eyes and hands ensures safety during operation. A sturdy workspace is also crucial. Keep your area tidy and organized. It helps prevent accidents and errors. A cluttered environment can lead to mistakes.

Additionally, software is a key necessity. It controls the CNC machine and helps design your projects. Learning this software takes time and practice. Expect some frustration; it’s part of the process. Mistakes will happen, and that’s okay. Every error is a chance to improve.

| Tool/Equipment | Description | Recommended Use |

|---|---|---|

| CNC Router | Computer-controlled machine for cutting various materials. | Ideal for woodworking and sign making. |

| CNC Plasma Cutter | Uses plasma to cut through metal sheets. | Best for metal fabrication and automotive work. |

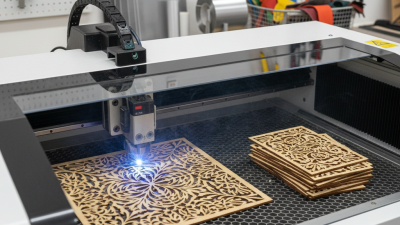

| CNC Laser Cutter | Uses high-powered laser to cut materials. | Suitable for precise cuts in wood, plastic, and fabric. |

| Cutting Tools | Includes bits, blades, and other cutting implements. | Choose based on material being cut and desired finish. |

| CAM Software | Software that converts CAD drawings to CNC instructions. | Essential for operation of CNC machines. |

| Safety Gear | Includes goggles, gloves, and ear protection. | Use to ensure safety while operating equipment. |

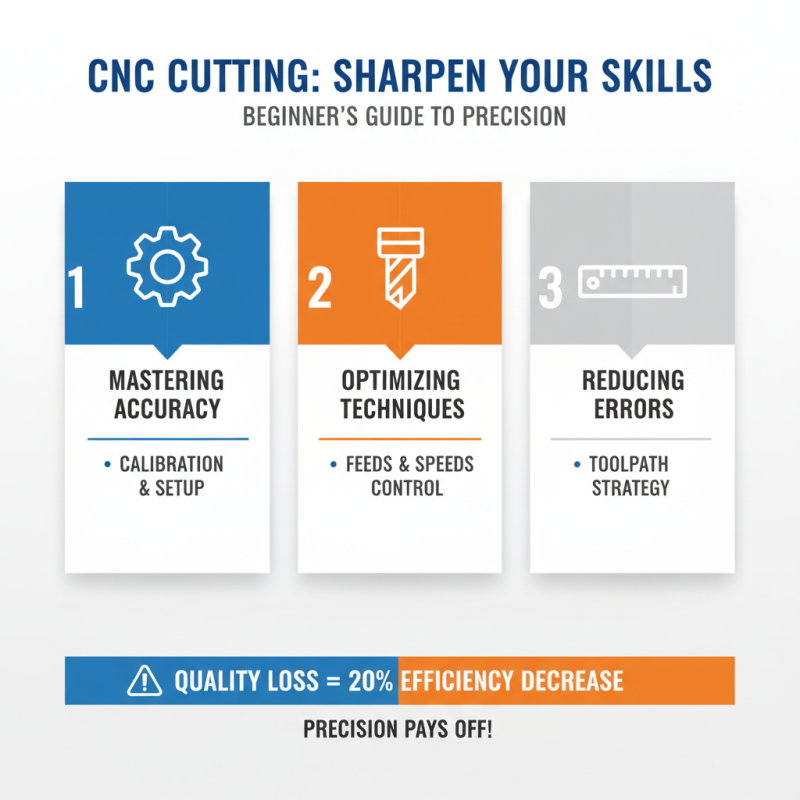

CNC cutting requires precision and skill. Beginners often struggle with accuracy. Understanding the key techniques can help sharpen your cutting abilities. Reports indicate that poor cutting quality can decrease efficiency by 20%. Here are some insights to consider.

Ensure your machine is calibrated correctly. Even slight misalignments can lead to errors. Regularly check your tool paths using software simulations. This can improve accuracy significantly. Data suggests that operators who simulate their cuts have 25% fewer mistakes. Consistent practice reinforces these techniques.

Also, focus on choosing the right materials. The type of material affects cutting performance. Softer materials may yield better results initially. Experiment with different speeds and feeds based on the material. Adjustments can lead to better finishes. Remember, practice does not always make perfect. Reflect on your process to recognize areas for improvement.

CNC cutting is a skill that requires attention to detail. Beginners often overlook common mistakes that can affect the quality of their work. One prevalent issue is incorrect tool selection. Using the wrong bit can lead to poor cuts and damage to the material. According to industry reports, a staggering 30% of new CNC operators report tool-related errors in their first year.

Another frequent mistake is improper material setup. If the material isn’t secured correctly, it can lead to misalignment during cutting. A misaligned piece can ruin an entire job. Research indicates that over 25% of waste in CNC projects stems from setup errors. It’s crucial to double-check your work before starting.

**Tip:** Always calibrate your CNC machine before a new project. This simple step can save time and reduce material waste.

Awareness of software settings is equally important. Overlooked parameters can alter the cutting path unexpectedly. A misunderstood parameter can lead to significant issues. The importance of reviewing settings cannot be overstated.

**Tip:** Create a checklist for your CNC setup process. This will help you catch potential mistakes early. Regularly updating your skills through online resources and workshops is advisable.

When setting up software for CNC cutting, precision is key. Many beginners overlook this vital step. Proper configuration can prevent costly errors. According to industry reports, about 30% of CNC issues arise from software misconfigurations. This statistic highlights the need for meticulous setup.

Design preparation is equally important. Always verify your CAD files before sending them to the CNC machine. Simple mistakes can lead to major setbacks. For instance, an improper scale can result in parts not fitting together. In fact, it's been found that nearly 25% of revisions stem from overlooked design errors.

Take time to review your designs. Small details, like line weights and dimensions, can make a big difference. Many beginners feel overwhelmed by software interfaces. It's a learning process, and it's okay to make mistakes. Reflect on what went wrong and adapt. Embrace ongoing learning to refine your skills. Each project is a chance to improve.