In today's competitive market, manufacturing efficiency can set a business apart. The choice of equipment plays a key role. A Laser Cutting Machine stands out among various options. It offers precision, speed, and versatility.

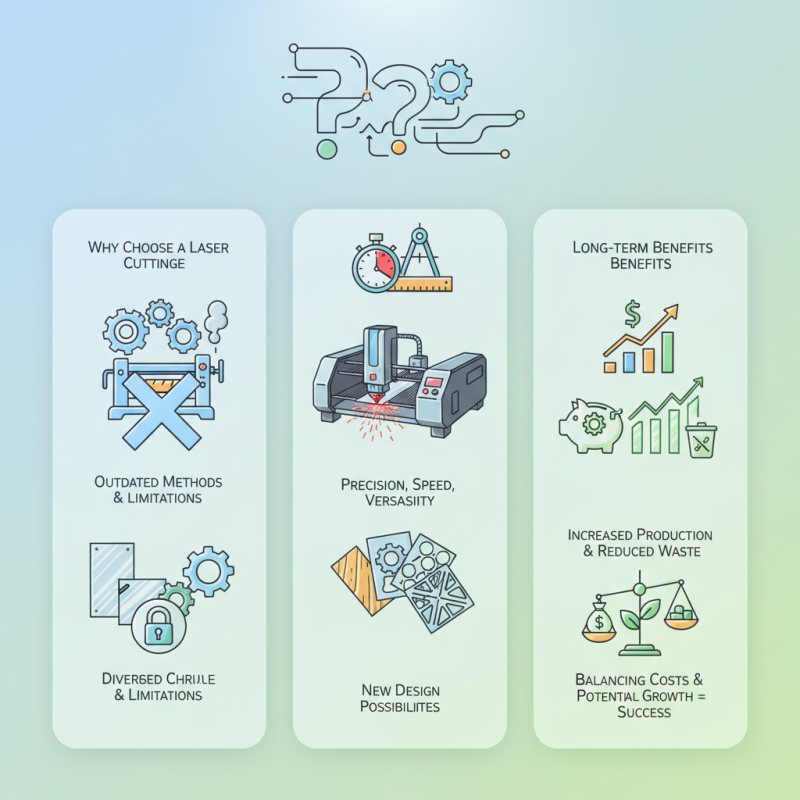

Many businesses today struggle with outdated methods. They often encounter limitations in materials and design. A Laser Cutting Machine can overcome these challenges. It can cut various materials, from metal to wood, with remarkable accuracy. This flexibility opens up new design possibilities.

Additionally, investing in technology requires careful thought. A Laser Cutting Machine presents an initial cost that can seem high. However, the long-term benefits are worth considering. Increased production rates and reduced waste can lead to a significant return on investment. Balancing costs with potential growth is essential for success.

Laser cutting machines have become essential tools for modern businesses. These machines are known for their precision and efficiency. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $5 billion by 2025. This growth indicates a significant shift in manufacturing processes.

One of the major benefits of using laser cutting technology is its accuracy. Laser cutters can produce intricate designs that traditional methods struggle to achieve. This level of detail allows businesses to cater to niche markets, enhancing creativity and innovation. Additionally, laser cutting minimizes waste. The process typically uses less material compared to other cutting methods. A study found that companies using laser cutting reported waste reductions of up to 30%.

However, it's important to note some challenges. Initial costs can be high. Not every business may afford the investment. Training staff also requires time and resources. Some companies may face operational hurdles when integrating this technology into existing workflows. Understanding these challenges is crucial for a successful transition to laser cutting.

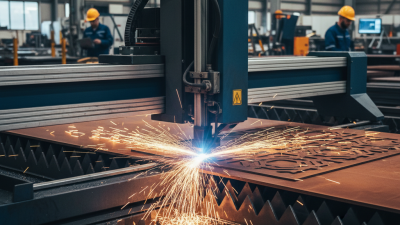

Laser cutting machines are transforming industries. They offer precision and versatility. Various technologies improve their functionality. For instance, CO2 lasers are excellent for cutting non-metal materials. They provide clean edges and minimal waste, which is crucial for businesses aiming for sustainability.

Fiber lasers, on the other hand, excel with metals. They cut quickly, reducing production time. This speed can lead to higher productivity and lower costs. However, it’s important to note that maintenance may be tricky. Proper upkeep is essential to avoid complications.

Additionally, many machines come with advanced software. This software enhances design capabilities and boosts efficiency. However, not every user finds it intuitive. Training time can be a hurdle for some businesses. Companies need to consider their team’s readiness before investing. The technology is impressive, but it requires commitment to fully harness its potential.

Laser cutting machines are increasingly popular in various industries. They offer significant cost efficiency compared to traditional cutting methods. Traditional techniques often involve high material waste. In contrast, lasers provide precision, leading to optimal use of raw materials.

Additionally, laser cutting reduces labor costs. Fewer workers are needed to operate these machines, which can limit expenses. However, the initial investment for laser cutting technology can be high. Many businesses hesitate, unsure if the long-term savings will justify this cost.

Moreover, the speed of laser cutting can sometimes be misleading. Quick output can lead to mistakes if adequate quality control is not in place. Careful planning and monitoring are essential to prevent these issues. Understanding both the advantages and potential pitfalls is crucial for any business considering laser cutting as a viable option.

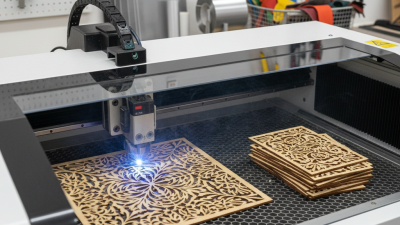

Laser cutting technology has transformed various industries through precision and efficiency. In manufacturing, it allows for intricate designs in metal and plastic. This precision minimizes waste and improves production time. The automotive sector benefits from laser cutting for creating complex parts. The accuracy ensures safer, more reliable vehicles.

In the fashion industry, laser cutting enables unique fabric patterns with clean edges. Designers can experiment with new shapes and styles. This technology also extends to woodworking. It helps artisans create detailed engravings and shapes in wood, enhancing their products' appeal.

**Tips:** When considering laser cutting, evaluate your material types. Different lasers suit specific materials better. Additionally, invest in training for operators to maximize the technology's benefits. Testing prototypes can showcase the machine's capabilities effectively.

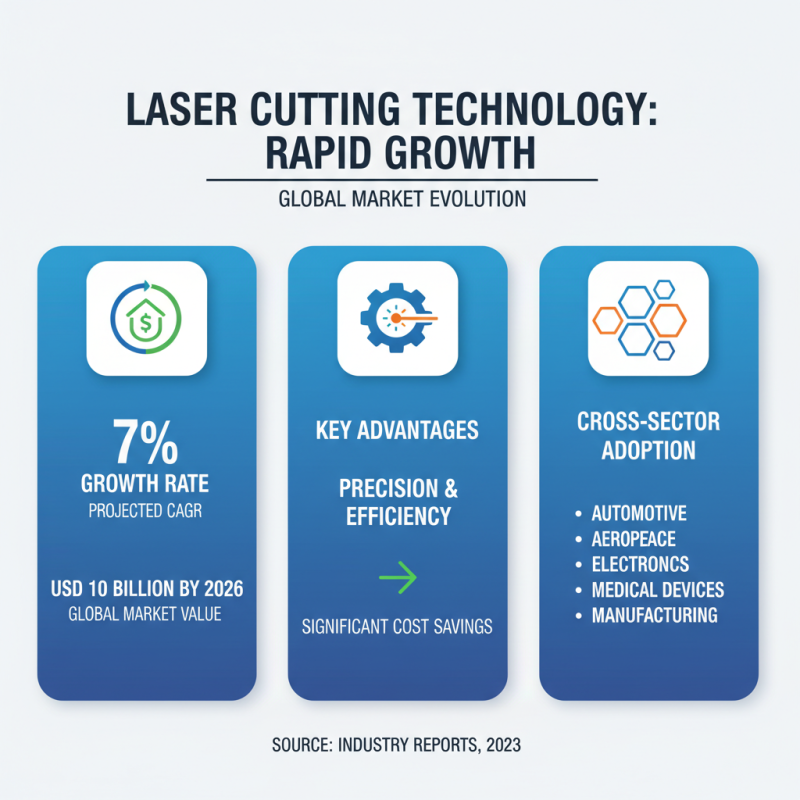

Laser cutting technology is rapidly evolving. Recent industry reports indicate a projected growth rate of over 7% in the global laser cutting market, expected to reach USD 10 billion by 2026. Such statistics highlight the technology's rising importance across various sectors. Businesses are adopting laser cutting for its precision and efficiency, which leads to significant cost savings.

However, companies must remain aware of some challenges. Integrating new laser systems can be costly and complex. There may also be a learning curve for operators unfamiliar with advanced technology. This transition requires training and adaptation, which can initially slow production. Yet, the long-term benefits often outweigh these hurdles.

Future trends suggest that the focus will shift towards automation and AI integration in laser cutting. This can enhance productivity and precision. A report from the International Federation of Robotics indicates that over 80% of companies are considering automation. However, the path to full automation presents its own difficulties. Businesses must balance initial investments with the expected return on investment carefully.