What factors affect the speed of laser tube cutting?

In the vast field of laser Tube Cutting, the importance of cutting speed is self-evident. So, what factors will affect the cutting speed of laser tube cutting?

1. Laser power

Generally speaking, the higher the power, the faster the cutting speed, just like a more powerful engine can make a car fly at lightning speed, and high-power lasers can penetrate pipes more quickly.

The Qiangang laser pipe cutting machine has multiple power options to choose from, which can perfectly meet different cutting speed requirements. Moreover, our pipe cutting machine adopts advanced lasers (Chuangxin/Kerui) with stable and reliable power, ensuring efficient cutting while greatly extending the service life of the equipment.

2. Material of pipes

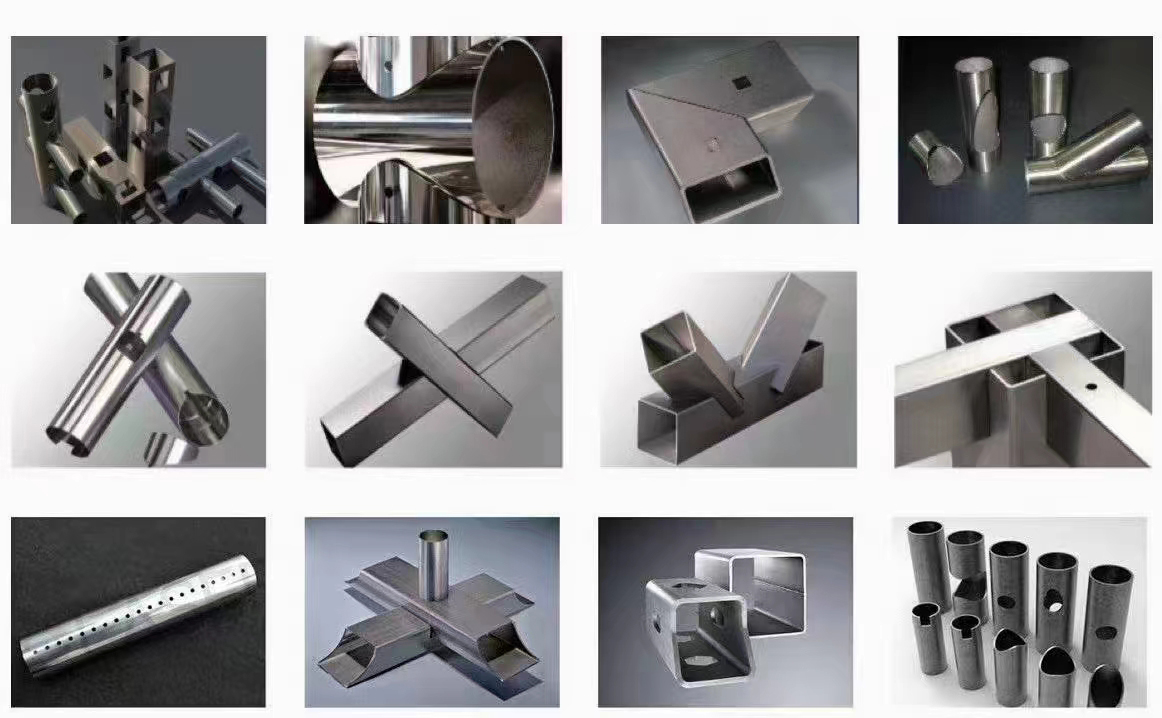

Different materials of pipes have varying degrees of absorption and reflection of laser. For high reflectivity metal materials such as copper and aluminum, the energy absorption of laser is relatively less, and the cutting speed may be slower than low reflectivity materials such as carbon steel; Compared to aluminum, stainless steel may require higher power and slower cutting speed. Moreover, the hardness of the material also affects the cutting speed, and harder materials usually require slower cutting speeds to avoid a decrease in cutting quality.

The Qiangang laser pipe cutting machine has been carefully optimized for different materials, and with its intelligent control system, it can automatically adjust parameters to ensure the best cutting effect.

3. Pipe thickness

Cutting thickness is undoubtedly a crucial factor, as thicker pipes naturally require more time for cutting.

The Qiangang laser pipe cutting machine has an incredibly powerful cutting ability, which can always maintain stable and efficient cutting speed for both thin-walled and thick walled pipes. Its high-precision transmission system can effectively ensure cutting accuracy and minimize errors to the greatest extent possible.

Auxiliary gas

The pressure and type of auxiliary gas will affect the cutting speed. Appropriate auxiliary gas pressure can effectively blow away slag, promote the cutting process, and improve cutting speed. Different types of auxiliary gases also have an impact on cutting speed, for example, oxygen can increase cutting speed for certain materials, but may cause oxidation of the cutting surface.

Focus position

The accuracy of the focal position is crucial for cutting speed. If the focal position is not accurate, the concentration of laser energy will decrease, thereby reducing the cutting speed. Generally speaking, when the focus is on the surface or slightly below the pipe, better cutting speed and quality can be achieved.

Equipment performance

The stability, accuracy, and response speed of the motion control system of laser cutting equipment all affect the cutting speed. Equipment with good performance can execute cutting instructions more quickly and accurately, thereby improving cutting speed.

Choosing Qiangang Laser means choosing peace of mind. We rely on excellent technology, professional services, and reliable product advantages to carefully create efficient laser cutting solutions for you, helping your enterprise stand out in fierce competition.