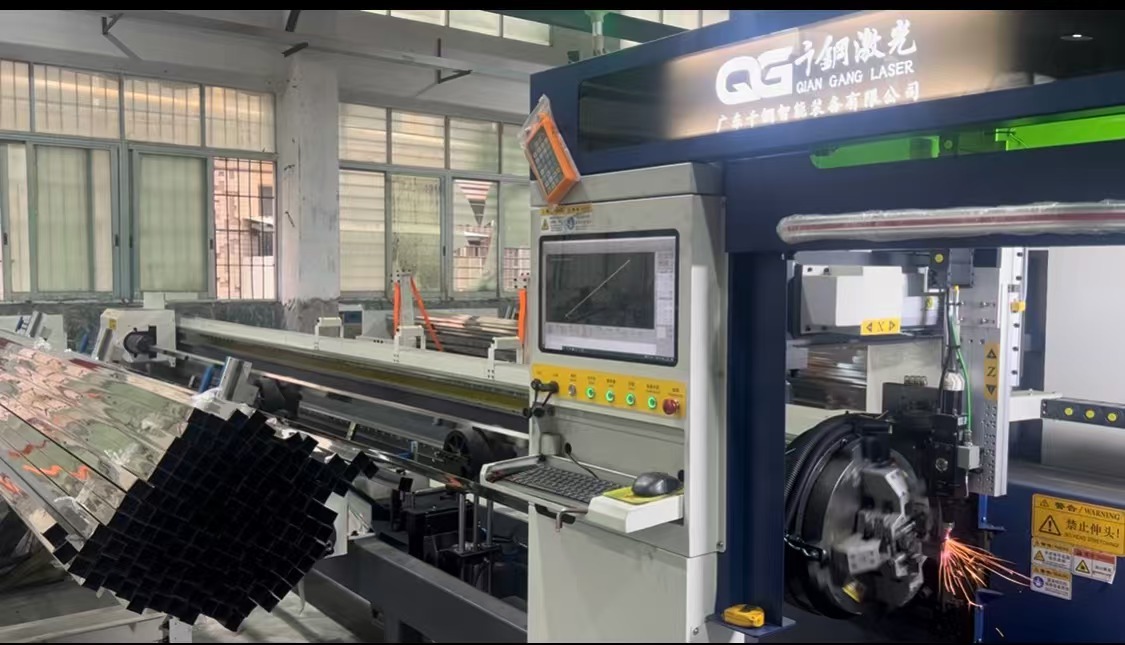

The new type of laser pipe cutting machine leads the industry transformation, and traditional equipment is facing elimination.

In the current era when the manufacturing industry is accelerating towards intelligence and high precision, Laser Pipe cutting technology has become a key force driving the transformation of the pipe processing field. However, while new laser pipe cutting machines are emerging in the market with advanced technologies, some enterprises are still using traditional laser pipe cutting machines. The gap between the two is gradually widening, becoming an important factor restricting the development of enterprises. Please provide the text you want to be translated.

The new type of laser pipe cutting machine has demonstrated an overwhelming advantage in cutting efficiency. After a well-known automotive parts manufacturing enterprise introduced this new type of laser pipe cutting machine, the pipe cutting efficiency achieved a leap, with an increase of up to 80%. This equipment is equipped with a high-speed motion control system and a high-power laser, and the cutting speed can reach several meters per minute. In contrast, traditional laser pipe cutting machines, due to technical bottlenecks, have a slow cutting speed and are difficult to meet the demands of large-scale and high-efficiency production, thus being at a disadvantage in the fierce market competition. Please provide the text you want to be translated.

In terms of cutting accuracy, the outstanding performance of the new laser pipe cutting machine is beyond the reach of traditional equipment. Its accuracy can be precisely controlled within ±0.02mm. Whether it is complex irregular pipe materials or precision pipe materials with strict accuracy requirements, it can handle them with ease, ensuring the consistency and stability of product quality. In contrast, traditional laser pipe cutting machines have relatively large cutting accuracy errors, resulting in uneven product quality. This not only increases the rate of defective products but also raises production costs, gradually losing their foothold in the high-end market competition. Please provide the text you want to be translated.

Intelligence and ease of operation are also significant advantages of the new type of laser pipe cutting machine. Operators only need to draw graphics on the computer through CAD/CAM software or import design files, and the equipment can automatically complete the cutting task, running intelligently throughout the process, which greatly reduces the professional skills required of operators. At the same time, the intelligent monitoring system equipped on the device can monitor the cutting process in real time. Once an abnormality occurs, it will immediately alarm and stop the machine, effectively avoiding production accidents and ensuring the smooth progress of production. Traditional laser pipe cutting machines are complex to operate, rely on manual experience, and lack intelligent functions. They are difficult to respond and adjust quickly during the production process and cannot adapt to the rapidly changing production demands of modern manufacturing. Please provide the text you want to be translated.

In addition, the new type of laser pipe cutting machine also performs well in energy conservation and environmental protection. Its advanced laser generator has a high energy conversion efficiency, significantly reducing energy consumption. Meanwhile, the efficient smoke and dust collection and treatment system effectively reduces environmental pollution, conforming to the development trend of green manufacturing. In contrast, traditional equipment not only has high energy consumption but also has limited capacity to handle the waste gas and residue generated during processing. With increasingly strict environmental protection requirements today, they are under great pressure to upgrade and transform. Please provide the text you want to be translated.

Nowadays, the new type of laser pipe cutting machines have been widely applied in numerous high-end manufacturing fields such as automotive manufacturing, aerospace, and medical devices, becoming an important engine to drive the high-quality development of the industry. Enterprises that still adhere to traditional laser pipe cutting machines should quickly recognize the technological gap and accelerate the pace of equipment upgrading; otherwise, they will become increasingly passive in the fierce market competition and gradually be eliminated from the market. Please provide the text you want to be translated.

Contact us

Our address and contact details

Address:Workshop No.2., Longzhen Road, Xincheng Industrial Zone, Shapu Village Committee, Jun’an Town, Shunde District, Foshan City, Guangdong Province(Laser machine Production base)

Contact Mobile: +8619886141247

Website: http://www.qglasermachine.com

Long Press Recognition Long Press Recognition Long Press Recognition

Follow Our Official Account Add WhatApp to Know More Add WeChat to Know More