In recent years, the demand for CNC laser cutters has surged significantly, driven by advancements in manufacturing technologies. According to a report by MarketsandMarkets, the CNC laser cutting machine market is projected to reach $4.4 billion by 2025. This growth highlights the importance of precision and efficiency in various industries, including automotive, aerospace, and metal fabrication.

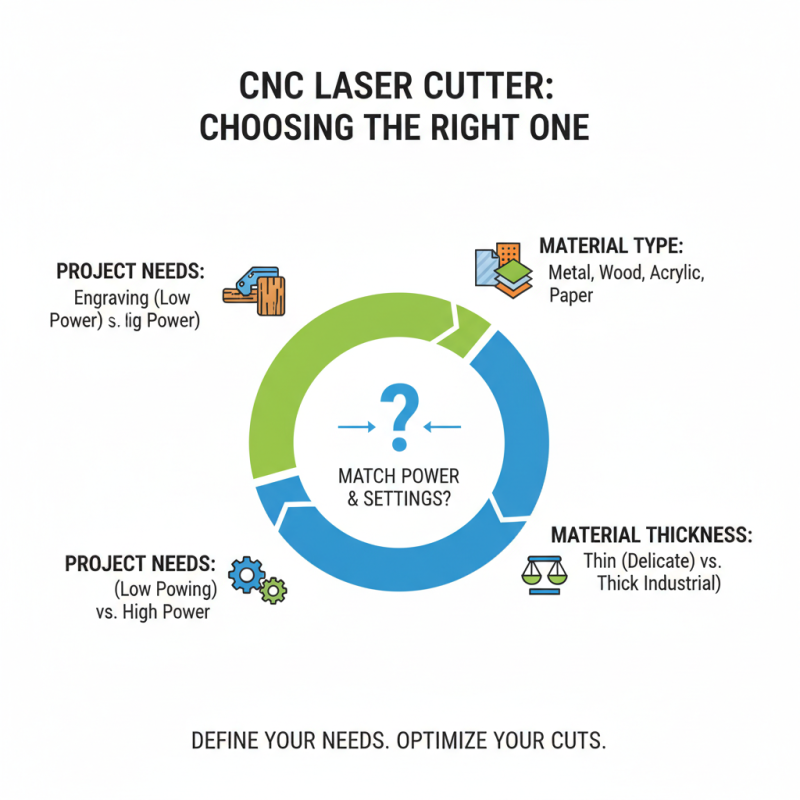

Choosing the best CNC laser cutter requires careful consideration. You must assess your specific needs, like material type and thickness. Lasers vary in power and capability. Factors such as speed, accuracy, and maintenance also play vital roles. It is crucial to find a machine that balances quality and cost-effectiveness.

However, the decision is not always straightforward. Many buyers overlook the importance of after-sales support and training. The practical application of cutting can differ from what is promised in specifications. Understanding your requirements can avoid costly mistakes. A thoughtfully selected CNC laser cutter can enhance productivity and drive innovation in your operations.

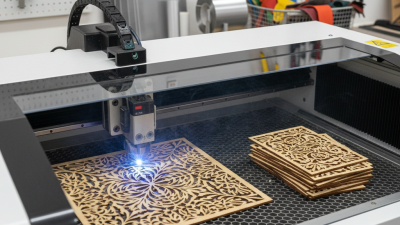

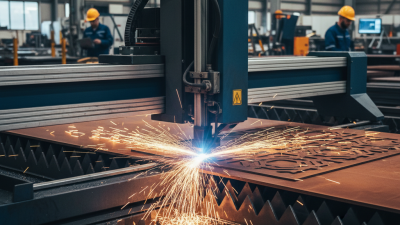

CNC laser cutting technology is a game-changer in many industries. It uses focused laser beams to cut through materials with precision. This method is popular for its speed and accuracy. Common materials include wood, metal, and plastic. The versatility of CNC laser cutters is impressive. They can create intricate designs that traditional cutting methods often struggle with.

Understanding the mechanics behind CNC laser cutting is crucial. The machine operates based on computer numerical control. This means that designs are programmed into the system. The laser cutter follows these designs accurately. However, not all machines are the same. Some may have limitations in material thickness or cutting speed. It's important to assess your needs carefully.

Despite its efficiency, laser cutting has challenges. Material types can affect the quality of cuts. Some materials may produce harmful fumes. Proper ventilation is necessary. Additionally, achieving the desired finish might require adjustments. Learning to operate and maintain the machine takes time. Mistakes can happen, but they are part of the learning curve. With careful consideration, CNC laser cutting can meet various manufacturing needs effectively.

| Specification | Details |

|---|---|

| Laser Type | CO2, Fiber |

| Cutting Area (mm) | 3000 x 2000 |

| Max Cutting Thickness (mm) | 20 (steel), 40 (acrylic) |

| Speed (m/min) | 20-100 |

| Power (W) | 100-4000 |

| Cooling Method | Water, Air |

| Software Compatibility | AutoCAD, CorelDRAW |

| Control System | DSP, USB |

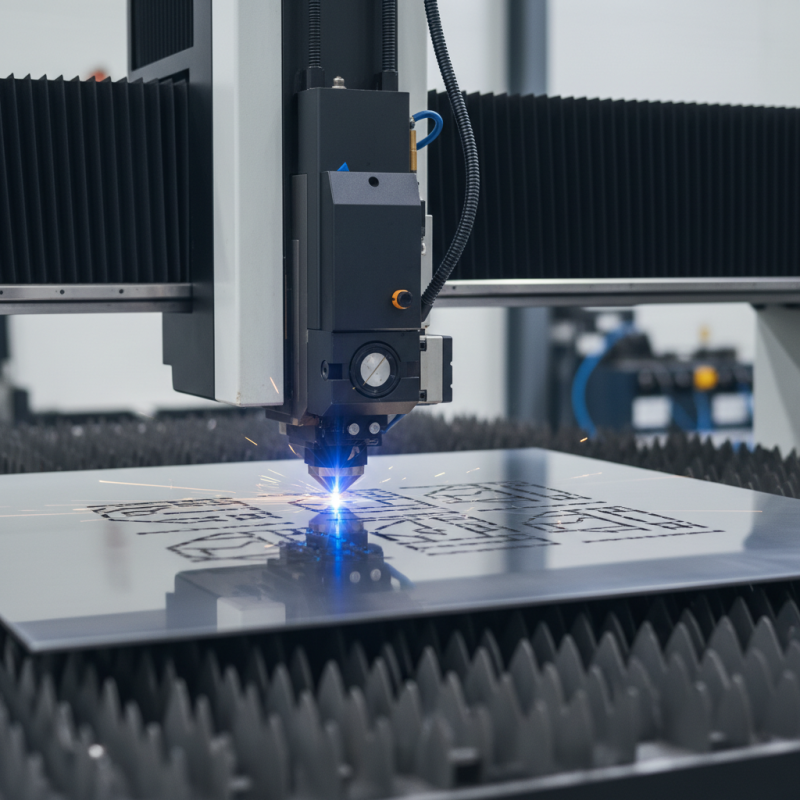

Choosing the right CNC laser cutter involves several key factors. Power is crucial. For example, a 100W laser cutter is suitable for materials like wood and acrylic. If you are working with metal, a higher wattage, such as 200W or more, may be necessary. The output power affects cutting speed and depth. Research shows that cutting speed increases linearly with power.

Another important factor is the bed size. Larger workpieces require more significant cutting areas. A 40" x 28" bed is common in many operations, but specific tasks may demand larger capacities. Consider your projects carefully. A mismatch here can lead to inefficient workflows.

Software compatibility also matters. Some CNC laser cutters come with proprietary software, which may not integrate well with your existing systems. Stay informed about the software capabilities. The correct software can significantly enhance productivity. Data indicates that companies with optimized software integration see a 20% increase in efficiency. Balancing these factors will lead to a more informed decision, ultimately affecting your production quality and speed.

When selecting a CNC laser cutter, understanding the types available is crucial. There are several styles to consider, including CO2, fiber, and diode laser cutters. CO2 lasers are versatile. They work well with materials like wood and acrylic. Fiber lasers, however, excel with metals. Their speed and efficiency make them popular for heavy-duty tasks. Diode lasers are compact and good for hobbyists.

Tips for choosing the right type include evaluating your primary materials. If you mostly cut wood, a CO2 laser would be a good fit. For metals, opt for a fiber laser. Consider the thickness of materials you'll use. Thicker materials require more powerful machines.

Another point to assess is the machine's features. Some models offer advanced software for easy design. Others provide better cooling systems. This can impact your workflow and project outcomes. Always think about your workspace. Larger machines need more room. Limited space could hinder your operations, or even result in accidents. Reflecting on your needs now can save trouble later.

When evaluating costs for CNC laser cutting, it’s essential to consider your budget carefully. The initial investment is key. Prices can vary widely based on machine features and capabilities. A lower-cost machine might seem appealing, but it may lack precision or durability. This could lead to higher long-term costs due to repairs or replacement.

Tips: Always think about the material you will use and its impact on pricing. Different materials have different cutting speeds and requirements, which can affect overall costs. Factor in not just the machine, but also maintenance costs.

Consider the additional expenses involved. Think about software, training, and setup. Unexpected costs can quickly add up. It's worth acknowledging that sometimes, saving upfront can lead to regret later. A more expensive machine might save you money in the long run by reducing waste and downtime.

Tips: Create a detailed budget. Track all potential expenses closely. Adjust your plans as needed; don’t be afraid to reassess your choices. Are you making the right investment? Regularly reflect on your needs and how well the technology serves them.

When choosing a CNC laser cutter, identifying your cutting needs is essential. Different projects require different approaches. For example, engraving wood demands lower power than cutting acrylic. Assessing materials is crucial. Do you need to cut thick metal or delicate paper? Each material has specific requirements.

Understanding your application's scope can help narrow options. If you plan to do intricate designs, a machine that offers high precision is necessary. Consider speed too. A faster cutter may improve efficiency, but accuracy shouldn't be sacrificed. Some projects might require slower speeds for detailed work.

Think about your workspace and budget as well. Not all machines fit comfortably in every shop. A larger machine may not work if space is tight. Costs can add up quickly when including software and maintenance. It’s worth reflecting on what you can realistically manage. Ultimately, aligning your needs and machine capabilities is key to making an informed decision.