In the evolving landscape of manufacturing, the Fiber Laser Cutting Machine has emerged as a cornerstone technology. Reports indicate that the fiber laser market is anticipated to grow substantially, reaching $2.9 billion by 2026. This growth highlights the importance of optimizing such machines for improved efficiency and output. The right adjustments can enhance cutting speed, reduce waste, and improve overall product quality.

To fully leverage the capabilities of your Fiber Laser Cutting Machine, understanding key operational aspects is crucial. Regular maintenance, proper calibration, and appropriate material selection can significantly impact performance. However, amidst the complexity of cutting processes, many operators overlook minor yet vital adjustments. A small oversight can lead to subpar results, ultimately affecting production timelines and costs.

Investing in training and technological upgrades is essential. A well-optimized Fiber Laser Cutting Machine can make a substantial difference in productivity. Keep in mind that continuous improvement is a journey. An open mindset towards reflection and adaptation can unveil new opportunities for excellence in laser cutting operations.

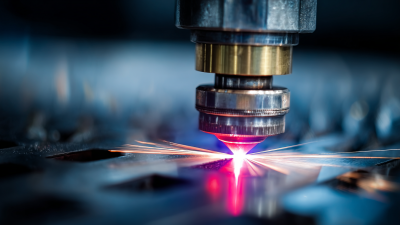

Fiber laser cutting technology has transformed industrial manufacturing by offering precision and speed. This method uses focused light beams to cut through various materials. Metal sheets, plastics, and even wood can be efficiently processed. Understanding its mechanisms is the first step to optimizing performance.

Power settings are crucial. Higher power can cut faster but may burn or warp thin materials. It's a fine balance between speed and quality. Experimenting with different speeds is essential. The wrong speed can lead to poor edges and increased waste. Properly adjusting the focal point is another key aspect. An incorrect focus can lead to inconsistent cuts.

Additionally, maintaining your machine is vital. Regular cleaning and calibration help sustain performance. However, neglecting preventive maintenance can cause issues. Users may overlook the importance of daily checks, which can lead to bigger problems. Reflecting on these aspects enhances efficiency and product quality in the long run. Investing time in understanding the intricacies of fiber laser cutting pays off.

| Tip Number | Tip Description | Expected Impact |

|---|---|---|

| 1 | Maintain optimal focus length | Improved cut quality |

| 2 | Regularly clean lenses and mirrors | Increased efficiency and reduced downtime |

| 3 | Use the correct cutting speed for materials | Enhanced material finish |

| 4 | Optimize gas type and pressure | Better cutting performance |

| 5 | Choose the right lens for the thickness | Optimized energy usage |

| 6 | Control material temperature before cutting | Reduced warping |

| 7 | Enable proper ventilation | Cleaner cuts |

| 8 | Upgrade software for machine control | Enhanced automation capabilities |

| 9 | Perform regular machine maintenance | Increased longevity of the machine |

| 10 | Train operators regularly | Reduced operational errors |

When optimizing fiber laser cutting performance, several key factors come into play. The quality of the laser beam remains paramount. A well-focused beam ensures precision cutting, while a weak beam may lead to poor edge quality. Make sure to regularly check the lens and mirrors for dirt or damage. Clean them often. Remember, a tiny smudge can disrupt the entire cutting process.

Another critical element is the type of material used. Different materials react uniquely to laser cutting. For instance, stainless steel requires different settings than aluminum. Always have a clear understanding of material properties. Incorrect settings can lead to burn marks or incomplete cuts. Experimentation often leads to better results, but be cautious. Overreaching can lead to wasted materials and frustration.

Finally, airflow is often overlooked. Proper gas flow cools the material and improves cut quality. Insufficient airflow can lead to oxidation or warping. Ensure that gas pressure and flow rates are aligned with material requirements. These seemingly small details can profoundly impact your overall productivity and the quality of your cuts. Adjusting these factors may take time and consideration. Stay attentive to the machine's performance and make necessary tweaks for better outcomes.

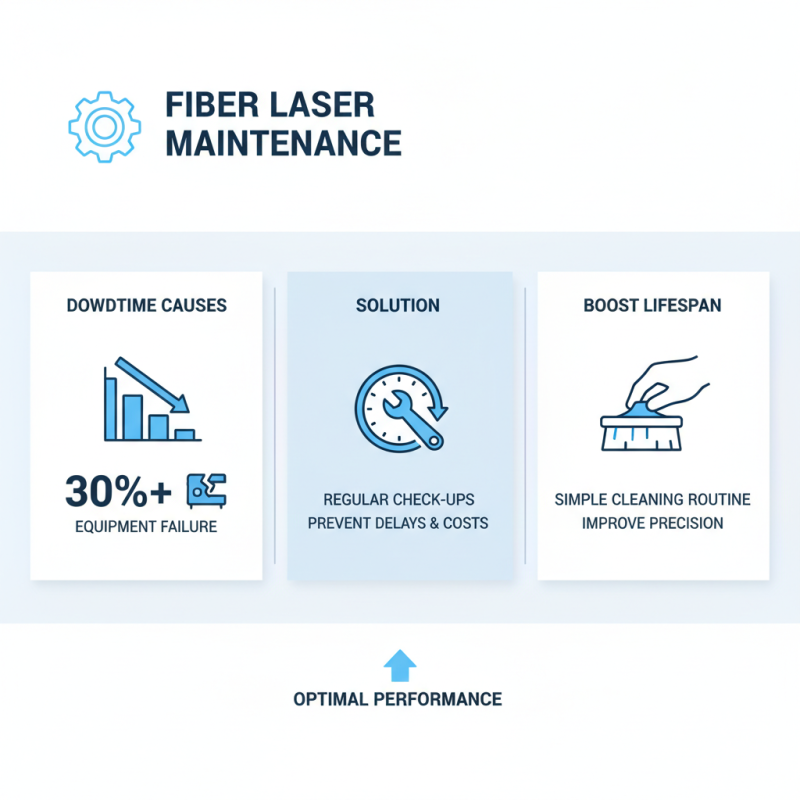

Regular maintenance is crucial for maintaining the performance of your fiber laser cutting machine. According to industry reports, over 30% of production downtime is caused by equipment failure. Regular check-ups can help avoid significant delays and unexpected costs. A simple cleaning routine can significantly increase the lifespan of your machine. Dust and debris can accumulate, affecting precision.

Implementing a maintenance schedule is key. Aim to perform routine inspections monthly. Check for lens clarity, alignment, and proper coolant levels. This practice can improve efficiency and maintain cutting quality. Many operators overlook coolant maintenance. Yet, optimal coolant flow is vital for effective heat dissipation, preventing overheating.

Don’t underestimate the importance of training. Operators should be aware of common issues and basic troubleshooting. Some machines allow for self-diagnostics, which can alert you to potential problems. Neglecting these features may lead to missed opportunities for proactive maintenance. Regularly updating software also plays a role; outdated systems can slow down performance and impact cutting accuracy.

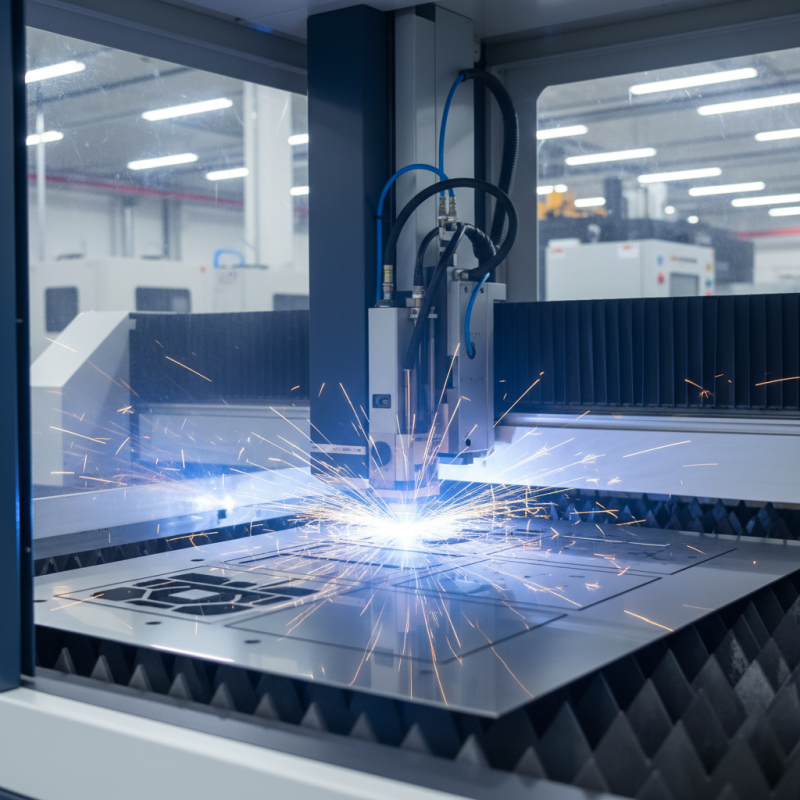

Optimizing cutting parameters is crucial for any fiber laser cutting machine. The right settings can dramatically affect efficiency and output quality. Start with the material type and thickness. Each has unique requirements. Adjusting the feed rate can also help. A faster speed may reduce cut quality, while a slower speed might increase processing time unnecessarily.

Consider focusing on power settings. Too high power can burn edges. Too low can leave uncut material. A balance is key. Experimenting with different gas types, such as oxygen or nitrogen, can enhance the cut. Each gas alters the interaction with the laser, affecting the cut's smoothness and speed. Regular maintenance of the optics can’t be overlooked. Dirty lenses may obstruct the laser, leading to inconsistent results.

Reflecting on your machine’s performance is important. Are there frequent adjustments? Unexpected downtime can indicate an underlying issue. Sometimes, less is more; overly complicated setups can hinder efficiency. Regularly reassess your cutting parameters as materials and projects change. Aim for continuous improvement in your laser cutting processes.

When looking to improve fiber laser performance, advanced techniques play a crucial role. Using the right parameters can significantly impact cutting quality. For instance, optimizing the focus spot size directly affects the kerf width. A smaller focus leads to finer cuts, but it requires precise adjustments. Fine-tuning the lens positioning and beam quality is essential here.

Material processing demands a keen understanding of the substrate being used. For example, mild steel and stainless steel require different cutting speeds and power settings. A report by the Laser Institute of America indicates that proper settings can enhance cutting speeds by up to 40%. However, miscalculations can lead to dross formation, resulting in wasted material and time. It's vital to continuously monitor and adjust these parameters while ensuring consistency across different batches.

Moreover, automation can boost efficiency but comes with its challenges. Learning curves for skilled operators can be steep. The complexity in integrating software solutions for real-time adjustments often leads to temporary setbacks. A focus on staff training can counteract these issues, enhancing overall productivity over time. Balancing advanced techniques with practical application remains a critical consideration for optimizing performance.