In the world of DIY and home projects, selecting the right Metal Laser Cutting Machine for Home can be a daunting task. Expert John Smith, a well-known authority in laser technology, once stated, "Choosing the perfect laser cutter is about understanding your needs and the machine's capabilities." This perspective is crucial for homeowners looking to elevate their crafting experience.

When considering a Metal Laser Cutting Machine for Home, various aspects should be evaluated. Factors include power, precision, and user-friendliness. A machine powerful enough to cut through metal yet simple enough for home users can be rare. Many buyers overlook this balance, leading to unmet expectations.

Additionally, cost is a significant concern. High-quality machines can be pricey. Yet, cheaper options may compromise on performance. It's essential to reflect on how often you plan to use the equipment. Investing wisely can lead to impressive results, while poor choices can result in frustration. This journey requires thoughtful consideration to find the perfect fit for your home workshop.

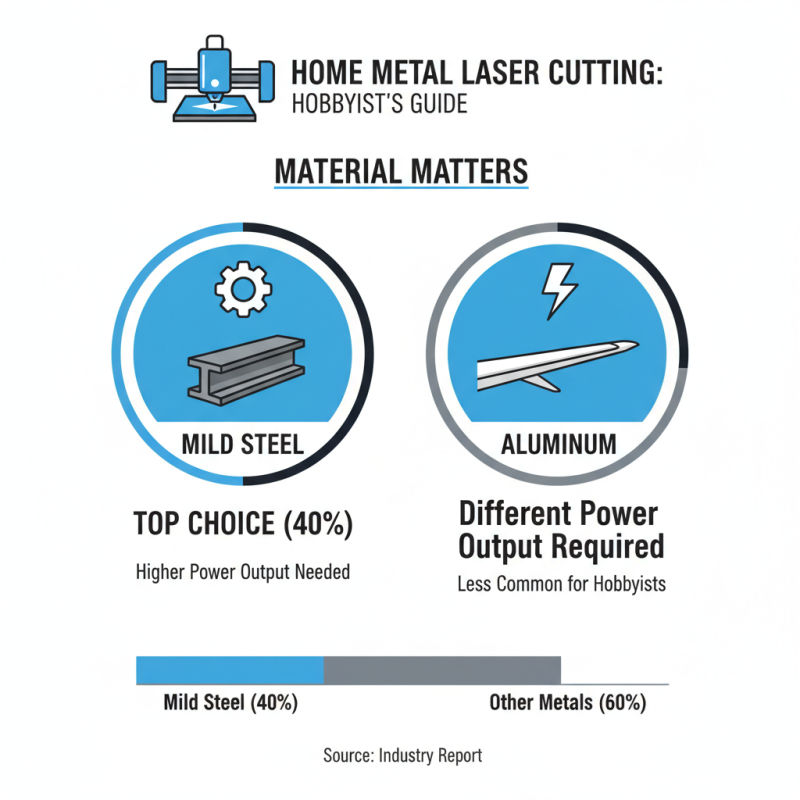

When choosing a metal laser cutting machine for home projects, understanding your specific cutting needs is essential. The material type plays a crucial role in this process. For instance, mild steel requires a different power output than aluminum. A recent industry report highlighted that mild steel is often the top choice for hobbyists, making up approximately 40% of home metal projects.

The thickness of the material is another vital consideration. Typically, machines can handle metal thicknesses ranging from 0.5 mm to 20 mm. However, many home users find that a maximum thickness of 10 mm is sufficient for crafting and DIY tasks. This helps in selecting a machine that balances power and efficiency.

Additionally, consider the intricacy of your designs. More complex patterns may require machines with advanced features, such as higher precision and faster processing speeds. Many entry-level machines might struggle with detailed work, showing inconsistencies. Ultimately, knowing what materials you’ll work with and their properties is your best guide to making the right choice. Researchers note that unexpected cuts can arise from improper machine settings. Thus, pay attention to both your needs and the limitations of the equipment.

When choosing a metal laser cutting machine for home use, power and speed specifications are crucial. The power level directly affects the cutting thickness and efficiency. A machine with higher wattage can cut through thicker materials quickly. However, it often comes at a higher price. Finding a balance is essential. If you only plan to cut thin sheets, a lower watt model could suffice.

Speed is another key factor. Faster cutting speeds can save time during projects. Yet, too much speed might sacrifice precision. It’s vital to consider what you will cut most frequently. Slower speeds can provide cleaner edges on intricate designs, while higher speeds work well for simpler cuts.

Keep in mind that specifications alone do not guarantee performance. There might be discrepancies between advertised power and actual output. User reviews can help gauge real-world performance. Experimenting with different settings is fundamental to achieve the best results. Adjusting speed and power based on the material type can lead to better finished products.

When exploring metal laser cutting machines, it's vital to compare various types. Fiber laser machines are widely recognized for their efficiency and precision. They use a highly focused beam, making them perfect for cutting thin materials. According to a recent industry report, fiber lasers can cut up to 30% faster than CO2 lasers. They offer minimal waste and reduced operational costs, which appeals to many users.

On the other hand, CO2 laser systems are versatile and can handle a range of materials. They're often preferred for thicker metals. Despite their capability, they may require more maintenance due to lens changes and other factors. An industry statistic indicates that CO2 lasers can have a lower upfront cost but may incur higher long-term expenses because of energy consumption.

Another type to consider is hybrid laser machines. These combine attributes of fiber and CO2 technologies. Their flexibility can be beneficial for hobbyists looking to work with different materials. However, they may not excel in specific tasks compared to dedicated machines. Users often find that a hybrid setup doesn’t always provide the precision needed for intricate designs.

When selecting a metal laser cutting machine for home use, assessing safety features is crucial. According to industry reports, about 30% of accidents in workshops occur due to inadequate safety measures. A machine equipped with an emergency shut-off switch can prevent serious injuries. Look for features like protective housing and laser safety interlocks. These elements ensure that the machine are only operational when safe to use.

Maintenance requirements are another vital aspect. Regular maintenance can significantly extend the lifespan of your machine. A 2022 report by the National Institute for Occupational Safety and Health highlights that poorly maintained equipment increases malfunction chances by 40%. Schedule monthly checks for lens cleaning and mechanical adjustments. This not only ensures precision but can also mitigate risks, as a well-maintained machine runs more reliably.

While it’s tempting to overlook the manual, doing so can lead to costly errors. Many users avoid reading it, assuming they can figure it out. This often results in misunderstanding safety protocols. The need for regular maintenance may seem daunting. However, neglecting these steps can create safety hazards and costly repairs.

Budgeting for a metal laser cutting machine is crucial for home projects. Industry reports show that entry-level machines typically range from $2,000 to $10,000. This price can increase based on cutting capabilities and features. It's essential to identify what is necessary for your needs. A higher price often signifies better precision or speed. However, sometimes, it can simply reflect brand reputation without substantial quality improvement.

Maintenance costs should also be considered. Some machines may require expensive parts or specialized service. Reports indicate that users can spend 10-20% of the initial investment annually on maintenance. This number varies depending on usage. Understanding future costs can prevent facing unexpected financial burdens.

It's easy to overlook these expenses. No one wants to face a budget shortfall later. Consider starting with a basic model and upgrading as skills improve. This approach allows for hands-on learning without a significant financial commitment. Reflecting on your budget can reveal different paths to success in metal cutting.