Choosing the right CNC laser cutter for metal can be challenging. There are many options in the market, each with its unique features. You need to consider your specific needs. For example, the size of the projects you handle and the materials you use matter significantly.

When looking for a CNC laser cutter for metal, pay attention to its power and speed. Some models excel at cutting thicker materials while others may struggle. Reading customer reviews is essential. It can help you understand each cutter's real-world performance.

Make sure to evaluate your budget, too. High-quality machines often come at a premium price. However, investing in a reliable CNC laser cutter for metal can improve your efficiency and precision. Reflect on what you truly need for your shop. Choosing wisely can lead to better results in your metal fabrication projects.

CNC laser cutting technology has transformed the way metal is processed in various industries. This method employs focused laser beams to cut, engrave, or mark materials with high precision. The versatility of CNC laser cutters makes them suitable for tasks ranging from intricate designs to heavy-duty fabrications. With CNC, a computer controls the laser, ensuring a level of accuracy that traditional cutting methods often struggle to achieve.

Applications of CNC laser cutting are vast. It’s commonly used in automotive, aerospace, and industrial manufacturing. Fine details in metal designs can be produced efficiently. This technology minimizes waste and enhances productivity. However, it is not without its challenges. Operators must consider factors like material type and thickness. User experience plays a significant role in achieving optimal results. Training and knowledge gaps can lead to subpar outcomes. Thus, continuous learning in this field becomes essential.

When selecting a CNC laser cutter for metal, several key factors are crucial. The power of the laser is one of the most important. A higher wattage often means the ability to cut thicker materials more efficiently. Consider the types of metals you will be working with. Different metals require different cutting techniques. Research the suitable power settings for your projects.

Another vital aspect is bed size. A larger bed allows for bigger sheets of metal to be cut, which can save time. However, it may require a larger workspace. Pay attention to the focal length of the lens as well. It affects the quality and precision of the cut. Inconsistent focus can lead to poor edges and uneven surfaces.

Don't overlook the software compatibility. Make sure the cutter supports the design programs you use. Complex shapes require robust software to achieve desired outcomes.

Assessing your budget is also essential. A higher initial cost often doesn’t guarantee better quality. Some low-cost models may surprise users with performance. Reflect on how often you will use the machine. Rushed decisions can lead to frustration down the line.

When comparing different types of CNC laser cutters for metalworking, it's essential to consider several key factors. One significant aspect is the type of laser used. CO2 lasers are great for non-metal materials, while fiber lasers excel in cutting metals. Think about the thickness of the materials you plan to cut. Fiber lasers often deliver better efficiency with thicker metals. However, they might be more expensive.

The cutting speed also varies between different CNC laser cutters. Some models operate faster, which can lead to higher productivity. Yet, faster isn't always better. Sometimes, a slower speed ensures more precise cuts. Reflections on performance should guide your decision. Another factor is the power output, which can influence both cutting depth and speed. A powerful laser is effective but may also lead to more wear and tear.

Lastly, consider the maintenance aspect. Some machines demand regular upkeep, while others are more user-friendly. You'll want a balance between advanced technology and manageable maintenance needs. Researching these differences can help you make an informed choice. Embrace the learning curve; each option has unique advantages and limitations. Consider your specific needs before settling on a choice.

When evaluating laser cutting speed and precision, a few critical factors come into play. Speed is often measured in inches per minute (IPM) or millimeters per second (mm/s). A recent industry report states that a high-end CNC laser cutter can achieve speeds up to 1,200 IPM. However, higher speed may compromise precision. A balance is crucial.

Precision is typically indicated by the kerf width, which is the width of the cut made by the laser. For metals, an optimal kerf width can be as narrow as 0.1 mm. Depending on the material's thickness and type, this can both increase and decrease cutting quality. Engineers often need to test different settings to find the sweet spot.

User experience also matters. Many operators encounter issues when the cutting speed is too high for intricate designs. This oversight can lead to uneven edges and increased waste. It’s essential to assess your projects' requirements against the cutter's capabilities. Careful consideration of these factors can significantly influence outcomes. Reflections on past projects help refine future selections and improve overall cutting efficiency.

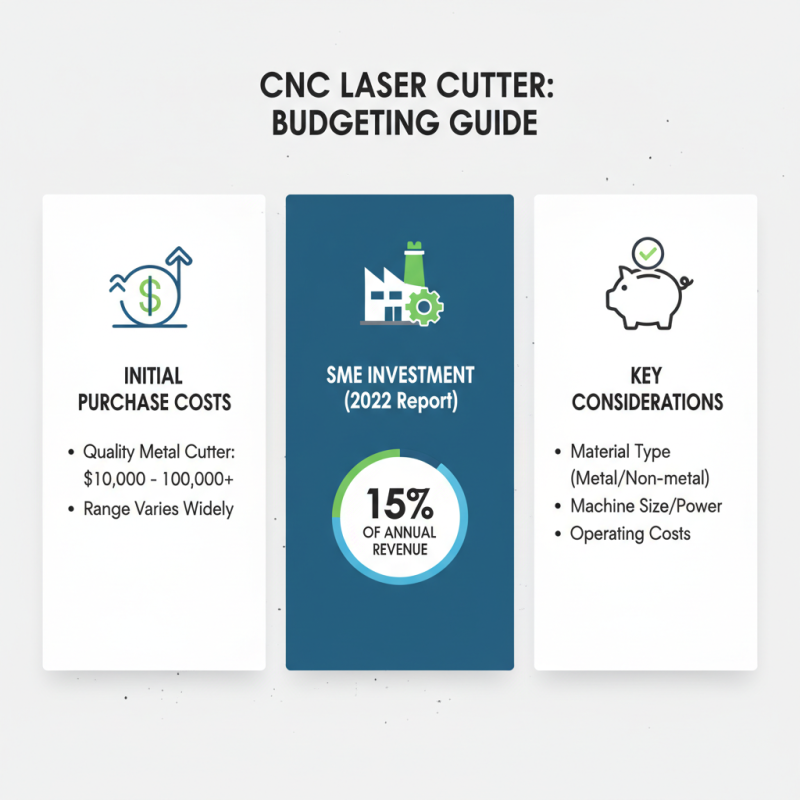

Choosing a CNC laser cutter requires careful budgeting. Initial purchase costs can range widely. For a quality metal cutter, prices typically start at $10,000 and can exceed $100,000. A 2022 industry report indicated that small to medium enterprises often spend around 15% of their annual revenue on such equipment.

Maintenance costs also play a crucial role in budgeting. Regular servicing is essential to ensure the cutter operates efficiently. On average, businesses should allocate about 5-10% of the machine's purchase price annually for maintenance. This includes parts replacement and service fees. Unexpected repairs can strain budgets. A breakdown could lead to costly downtime.

Investing in training for staff is another aspect to consider. Proper training can reduce operational errors and enhance productivity. An industry survey found that companies investing in staff training saw a 20% decrease in errors. Overall, being aware of all costs involved helps in making a more informed choice.