Selecting the right Fiber Laser Cutter for your business is a crucial decision that can significantly impact your operations, productivity, and overall competitiveness. As industries increasingly adopt advanced manufacturing technologies, the demand for efficient and precise cutting solutions has surged. A Fiber Laser Cutter stands out due to its speed, precision, and versatility, making it a preferred choice for various applications, from metal fabrication to intricate design work. However, with numerous models and features available, navigating the selection process can be overwhelming.

When choosing a Fiber Laser Cutter, it’s essential to assess your specific business needs. Factors such as material types, thicknesses, and desired cutting speeds play a critical role in identifying the most suitable machine. Additionally, understanding the capabilities of different laser technologies can help you make an informed choice. It’s not just about the initial investment; considering the long-term operational costs and maintenance requirements will also ensure that you select a reliable tool that aligns with your growth and production goals. This guide aims to provide a structured approach to help you identify the best Fiber Laser Cutter that fits your unique business requirements, empowering you to enhance your production capabilities while optimizing efficiency and cost-effectiveness.

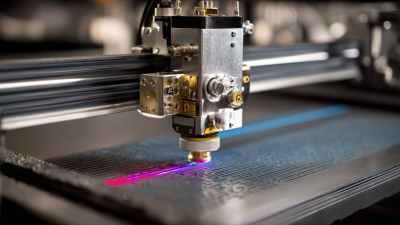

Fiber laser cutting technology has emerged as a game changer in various manufacturing sectors due to its precision and efficiency. Unlike traditional cutting methods, fiber lasers use solid-state laser sources to generate high-intensity light that can easily cut through a wide array of materials including metals, plastics, and composites. According to a report by MarketersMedia, the fiber laser cutting market is projected to reach USD 6.69 billion by 2026, growing at a compound annual growth rate (CAGR) of 7.9%. This rapid growth underscores the technology's increasing adoption in industries such as automotive, aerospace, and metal fabrication.

The applications of fiber laser cutting are vast and versatile. Its ability to provide clean cuts with minimal thermal distortion makes it ideal for intricate designs and high-precision parts manufacturing. A report by ResearchAndMarkets highlights that the automotive sector, in particular, is expected to significantly drive the demand for fiber laser cutters due to their capability to enhance productivity and reduce operational costs. Moreover, fiber lasers are better suited for cutting thick materials compared to CO2 lasers, making them a superior choice for heavy industry applications, with studies indicating a cutting speed increase of up to 30% in certain conditions.

As businesses evaluate their cutting needs, understanding the specific advantages and applications of fiber laser cutting technology is crucial. Not only does it allow for faster turnaround times, but it also minimizes waste and energy consumption, aligning with the growing emphasis on sustainability in manufacturing. Industry projections suggest that firms investing in this technology will gain a competitive edge, highlighting the importance of choosing the right fiber laser cutter tailored to specific operational requirements.

This chart illustrates the maximum cutting speeds of various fiber laser cutter power options, showcasing how increased power levels correspond to enhanced cutting speeds. Businesses can use this information to choose the laser cutter that best fits their operational requirements.

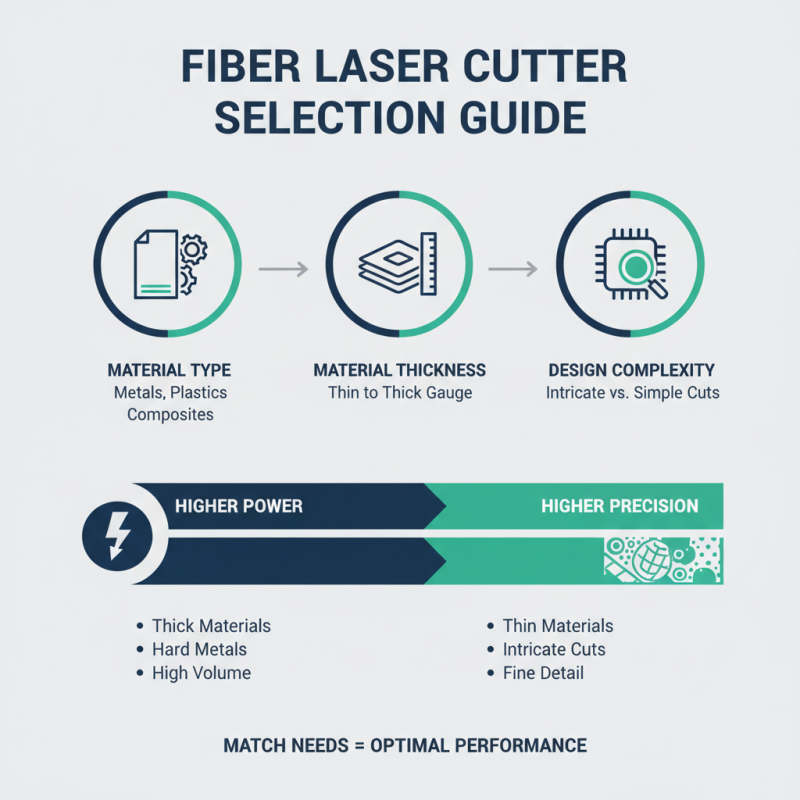

When selecting a fiber laser cutter for your business, it’s crucial to first identify your specific cutting needs and requirements. Consider the materials you commonly use, as different fiber lasers excel at cutting various substances such as metals, plastics, and composites. For instance, if your production involves intricate designs in stainless steel, you may require a machine with higher power and precision capabilities. Assessing the thickness of the materials is equally important; thicker materials may necessitate a cutter with higher wattage to achieve clean cuts efficiently.

Another key factor is the desired cutting speed and production volume. If your business requires rapid prototyping or high-volume production runs, a fiber laser cutter with advanced speed settings and automation features would be beneficial. Additionally, think about the size of the parts you typically work with, as the cutting bed's dimensions should accommodate your largest pieces. Finally, consider any additional functions you might need, such as engraving or marking, which could add versatility to your operations. By thoroughly evaluating these factors, you can make a well-informed choice that aligns with your specific business objectives and enhances your production capabilities.

When evaluating fiber laser cutters for your business, it is crucial to focus on key features that directly impact performance and efficiency. One of the primary aspects to consider is the laser power, typically measured in watts. Higher wattage provides the ability to cut through thicker materials at faster speeds, making it essential for businesses that require high production rates or work with various material thicknesses. It is also important to assess the cutting speed; the faster the cutter can move, the more efficient the operation will be, allowing for greater throughput in a given timeframe.

Another significant factor to consider is the type of cooling system employed by the laser cutter. An efficient cooling system ensures that the machine operates at optimal temperatures, leading to consistent performance and extended lifespan. Additionally, examining the software compatibility and ease of use can significantly affect productivity. User-friendly interfaces allow for quicker training of staff and seamless integration with existing design programs. Overall, a thorough understanding of these features will help businesses select the right fiber laser cutter that aligns with their operational goals and production needs.

| Feature | Description | Importance |

|---|---|---|

| Power Output | The maximum laser power, typically ranging from 1000W to 6000W. | High power is crucial for cutting thicker materials. |

| Cutting Speed | The speed at which the cutter can operate, measured in mm/min. | Faster cutting can enhance productivity. |

| Material Compatibility | The range of materials the cutter can effectively process. | Versatility in materials expands business opportunities. |

| Cooling System | System that maintains optimal temperature for the laser. | Prevents overheating and prolongs equipment life. |

| Software Compatibility | Compatibility with design software and CAD programs. | Ease of integration into existing workflows. |

| Automation Features | Options for automation, such as automatic loading/unloading. | Increases efficiency and reduces manual labor. |

| Maintenance Requirements | Amount of maintenance needed for optimal operation. | Lower maintenance can reduce downtime and costs. |

| Safety Features | Inbuilt safety mechanisms to protect users and equipment. | Essential for compliance and worker safety. |

When choosing a fiber laser cutter for your business, it's essential to compare different brands and models to find the one that aligns with your specific needs. Factors such as cutting speed, material compatibility, and precision should be prioritized. Some models may excel in cutting thicker materials, while others offer advanced features for intricate designs. Researching user reviews and industry comparisons can provide valuable insights into the reliability and performance of various options.

Tips: When evaluating different fiber laser cutters, consider conducting a hands-on demonstration. This allows you to assess the machine's ease of use, setup time, and overall functionality in a real-world environment. Additionally, it's crucial to examine the after-sales support and warranty options provided by each manufacturer, as this can significantly impact your long-term satisfaction and operational efficiency.

Another key aspect to consider is the software compatibility of the fiber laser cutter. Some models come with user-friendly interfaces and design software that facilitate smoother operation and integration with existing systems. Look for machines that offer extensive training resources and community support, which can ease the transition and boost productivity in your business.

When assessing the budget for a fiber laser cutter, it's essential to consider not just the initial purchase price but also the long-term costs associated with ownership. This includes maintenance, operational expenses, and potential upgrades. A lower upfront cost may be enticing, but if the machine requires frequent repairs or uses more energy than anticipated, the savings can quickly evaporate. Evaluating the total cost of ownership over a span of several years will provide a clearer picture of the financial commitment involved.

**Tips:** One effective way to estimate long-term operational costs is to assess the average energy consumption of the cutter. Look for machines that boast high efficiency, as this can significantly reduce electricity bills. Additionally, consider the availability and pricing of replacement parts. Some less expensive models may have costly components that need replacing more frequently.

It's also wise to factor in the potential for scalability. As your business grows, your needs may change, and investing in a model that allows for easy upgrades or modifications can save you money in the long run. Consider options that offer flexible configurations so that you can expand your capabilities without needing another major investment down the line.