In the realm of precision engineering, the significance of Tube Laser Cutting cannot be overstated. Renowned expert, Dr. Emily Carter, once stated, "Tube Laser Cutting represents the future of accurate and efficient fabrication." Her insights highlight how this technology reshapes manufacturing. As industries demand higher precision and speed, choosing the right laser cutting machine is crucial.

Today, we explore the top five tube laser cutting machines that excel in delivering accuracy and efficiency. Each machine has unique features, catering to diverse industrial needs. However, not every machine may perfectly align with every user's requirements. It's vital to understand the specific applications and limitations of each option before making a decision.

Many engineers overlook subtle differences between the machines. Some may underestimate the importance of cutting speed versus precision. In contrast, others may prioritize cost over quality. Reflecting on these choices can lead to better investments in Tube Laser Cutting technology. The right machine can greatly enhance productivity and create exceptional results.

Tube laser cutting technology has transformed precision engineering. This technology enables manufacturers to cut various metals with extraordinary accuracy. Reports indicate that the global market for laser cutting machines is projected to grow at a CAGR of 6.5% from 2023 to 2028, indicating a robust demand in industries like automotive and aerospace.

Applications of tube laser cutting are vast. It is used in creating structural components, automotive parts, and medical devices. The precision level allows for intricate designs, which enhance product performance. However, businesses sometimes struggle with the initial investment and maintenance costs. This reality can limit accessibility for smaller enterprises. Additionally, improper training can lead to safety risks and inefficiencies.

Efficiency is a key benefit of tube laser cutting, speeding up production times while reducing material waste. Expect a typical scrap rate of about 5%, compared to higher percentages in traditional cutting methods. Nonetheless, not every application suits this technology. It’s essential to evaluate specific project needs before transitioning to tube laser cutting systems.

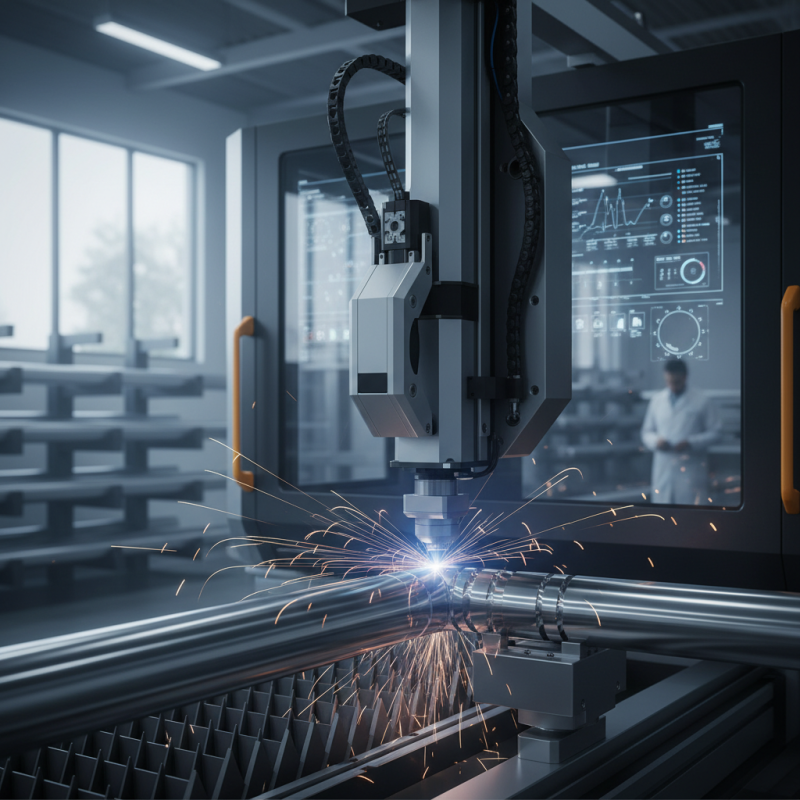

When selecting the best tube laser cutting machines, precision is key. Look for machines that offer high accuracy in cutting. This minimizes waste and maximizes efficiency. In addition to precision, consider the machine's speed. Faster machines can increase productivity, but ensure they maintain cutting quality.

Tip: Inspect the machine's software features. Advanced software can greatly enhance design flexibility. A user-friendly interface can save valuable time during operation.

Check for compatibility with various materials. A versatile machine can handle different tube types and thicknesses. This flexibility can be a game-changer for shops with diverse projects.

Tip: Don't overlook after-sales support. Reliable service and maintenance can prevent costly downtimes.

Finally, evaluate the machine's overall build quality. A robust construction often translates to longevity and consistent performance. But remember, not all high-end machines fit every shop's needs. Reflect on your unique requirements.

When it comes to precision engineering, tube laser cutting machines are essential. These machines offer accuracy and efficiency, leading to better production outcomes. According to a recent industry report, the demand for tube laser cutting technology has increased by 15% over the past few years. This growth is driven by advancements in machine speed and cutting quality.

Precision is crucial in engineering applications. Tube laser cutting machines can achieve tolerances of ±0.1 mm, making them ideal for complex geometries. The ability to cut various shapes and materials offers flexibility in design. However, some machines struggle with certain tube diameters or materials, which may require adjustments or additional processes.

Additionally, the energy consumption of laser machines can be significant. Reports show that modern machines can consume up to 60% less energy than older models. Still, there’s room for improvement. Companies must continuously evaluate efficiency to minimize costs and environmental impact. Balancing performance, energy use, and precision is a challenge many manufacturers face today.

When it comes to tube laser cutting machines, precision is key. These machines excel in cutting various materials with high accuracy. Many models feature advanced technology that ensures clean and burr-free edges. This leads to less time spent on finishing work, directly impacting productivity.

One notable feature is the ability to handle complex shapes and angles. This versatility opens doors for innovative designs in engineering projects. However, it’s worth noting that while these machines offer great benefits, they also require proper maintenance. Users must stay vigilant with routine checks to ensure optimal performance.

Another significant benefit is the speed of operation. Tube laser cutters can process materials quickly, making them suitable for high-volume production. Still, some users find the initial investment daunting. Choosing the right model may seem overwhelming, but extensive research pays off in the long run. A careful approach to selection is essential for achieving the desired results.

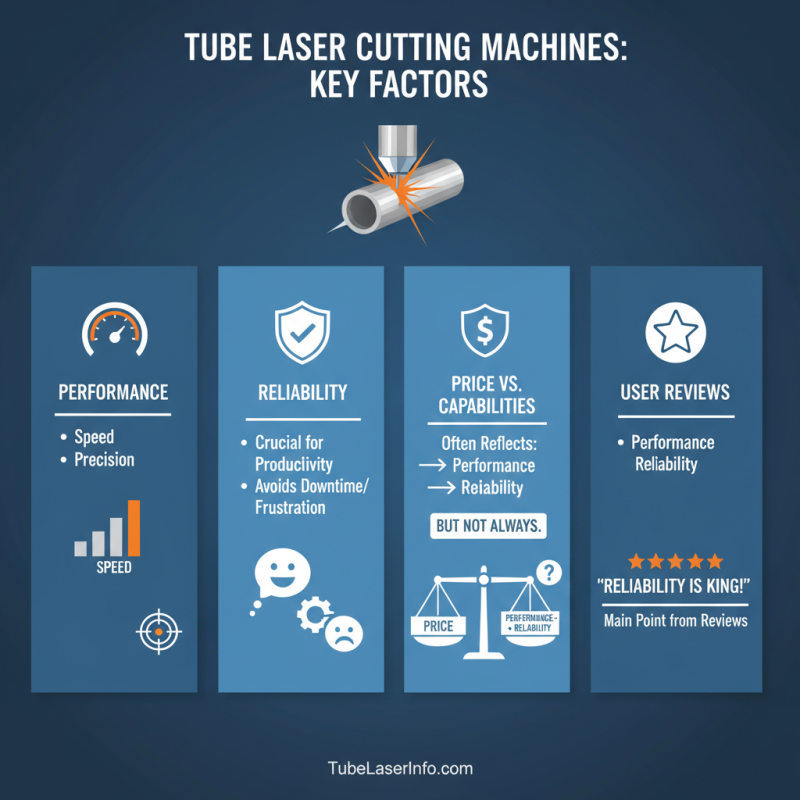

When it comes to tube laser cutting machines, performance is crucial. Many machines offer varying speeds and precision levels. User reviews highlight the importance of reliability. Machines that frequently malfunction can hinder productivity and lead to frustration. Price often reflects these capabilities, but not always.

Tips: Always consider the warranty. A good warranty can save costs long-term. Check customer feedback for real-world insights.

Some machines might promise high speed, yet fail to maintain accuracy. This discrepancy can result in wasted materials and time. Users also mention the learning curve of more advanced models. It’s essential to balance features with employee training needs.

Tips: Invest time in training. A well-trained team maximizes machine efficiency. Don’t overlook maintenance; it ensures longevity.

Evaluating performance and user experiences is vital. Keep an eye on costs, but don’t compromise on quality. Look for machines that offer a balance between price and functionality.