In the rapidly evolving world of manufacturing, the significance of a CNC laser cutter cannot be overstated. Experts have praised these machines for their precision and efficiency. According to John Smith, a leading CNC automation expert, “The right laser cutter can redefine your production capabilities.” This statement echoes the sentiments of many in the industry.

The landscape for CNC laser cutters in 2026 showcases various models that excel in performance. As technology advances, manufacturers strive to develop devices that enhance cutting speed while maintaining accuracy. Innovations in software integration further enable seamless operation, although challenges persist in adapting existing workflows.

Despite notable progress, the quest for the perfect CNC laser cutter is ongoing. Each model comes with strengths and weaknesses. Some machines excel in intricate designs, while others focus on speed. It’s crucial to reflect on your specific needs before making a choice. Balancing cost, efficiency, and capability remains a challenging task for many businesses. The CNC laser cutter industry continues to evolve, pushing the boundaries of what’s possible in precision manufacturing.

CNC laser cutting technology has evolved dramatically over the years. This evolution has focused on increasing precision and efficiency. Some machines now utilize advanced software algorithms. These algorithms enhance accuracy, allowing for intricate designs. The result? Cleaner cuts and less material waste.

However, this progress is not without challenges. Not all operators fully understand the technology. Misinterpretations can lead to inefficiencies. Additionally, proper maintenance of machines is crucial. Neglecting routine checks can reduce precision over time. It’s a reminder that even advanced technology needs human oversight.

Moreover, the impact on industries is significant. Many sectors benefit from enhanced design capabilities. However, adapting to new technology requires training. There’s often a learning curve. Businesses must reflect on how they integrate these systems. Continuous improvement is necessary to fully harness the potential of CNC laser cutting.

| Model | Cutting Area (mm) | Laser Power (W) | Material Types | Precision (mm) | Efficiency (m/s) |

|---|---|---|---|---|---|

| Model A | 1300 x 900 | 150 | Wood, Acrylic | 0.05 | 1.2 |

| Model B | 1500 x 1000 | 300 | Metal, Plastic | 0.03 | 1.5 |

| Model C | 1200 x 800 | 100 | Wood, Leather | 0.07 | 1.0 |

| Model D | 1000 x 600 | 250 | Acrylic, Fabric | 0.04 | 1.3 |

| Model E | 2000 x 1400 | 400 | Aluminum, MDF | 0.02 | 1.8 |

When selecting a CNC laser cutter for 2026, precision is key. Look for machines with high accuracy ratings. A good cutter should have a repeatability of at least 0.01 mm. This small margin can make a big difference in intricate designs. Consider laser power too. More power allows for cutting through thicker materials, but it also requires careful management to avoid damage.

Another important aspect is the software compatibility. Modern CNC laser cutters should seamlessly integrate with design software. This ensures smoother operations and better workflow efficiency. User-friendly interfaces are essential. Operators should spend less time learning, and more time executing projects. Look for machine features that allow for easy adjustments. Some machines may offer auto-calibration functions, which can save you time.

Finally, think about support and maintenance. Regular upkeep is necessary for longevity. Machines with built-in diagnostics can help identify issues early. However, even with advanced technology, occasional breakdowns may still occur. Having access to reliable customer service can make the difference. These factors are essential in ensuring that your CNC laser cutter remains a valuable asset in your workshop.

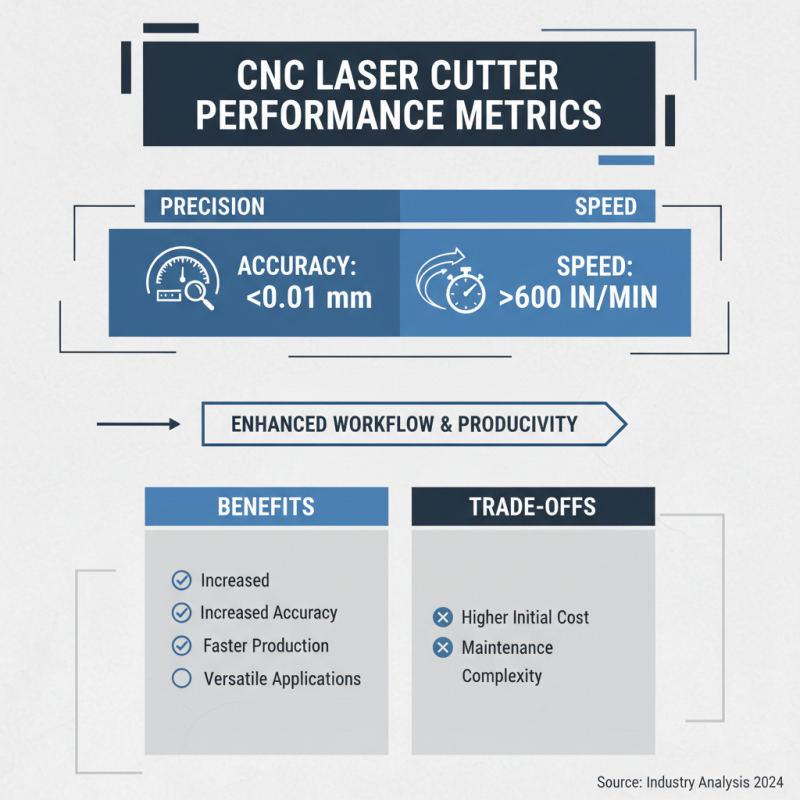

In the world of CNC laser cutters, precision and efficiency are paramount. Recent industry analysis shows that the top models offer accuracy within 0.01 mm and speeds exceeding 600 inches per minute. These parameters significantly enhance workflow and productivity in various applications, from intricate designs to large-scale productions. However, achieving such high performance can come with trade-offs, including maintenance challenges and higher initial costs.

Tip: Always evaluate the total cost of ownership when selecting a CNC laser cutter. Performance isn’t just about the purchase price.

High-precision models typically utilize advanced optics and controls. Reports suggest that these components can lead to a 20% increase in the overall cutting speed. Yet, users must be aware of the learning curve associated with these systems. Not every user will grasp the technology immediately, potentially limiting the return on investment.

Tip: Invest time in training staff on new equipment. Proper understanding can prevent costly mistakes and enhance efficiency.

Overall, manufacturers must balance the allure of cutting-edge technology with practical considerations. The best CNC laser cutters are not just about specs; they should fit within the operational framework of any workshop, ensuring both precision and ease of use.

In 2026, the market for CNC laser cutters is expected to grow significantly. The rise in demand stems from industries looking for precision and efficiency. Reports indicate that the CNC laser cutting market could reach $5.4 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.3%. This growth shows how important laser cutters have become in manufacturing and fabrication.

However, challenges remain. While many companies invest in CNC technology, not all achieve expected returns. According to industry surveys, 30% of firms reported issues with machine setup and calibration. Misalignment can lead to material waste and increased costs. Companies must refine their operational processes to avoid these pitfalls.

As consumer expectations rise, precision in cutting is non-negotiable. In metalworking, for example, small inaccuracies can cause significant quality issues in final products. Experts suggest that firms focus on training and skill development. A well-trained workforce can mitigate some issues. Yet, investing in technology alone is not enough; continuous improvement and adaptations are crucial for long-term success.

Investing in CNC laser cutters can be a game changer for small businesses. These machines offer precision and speed. However, the initial cost can be overwhelming. Weighing benefits against expenses is crucial for smart decision-making.

Consider your production volume. If you need to create high-quality products frequently, a CNC laser cutter may save time. Increased efficiency can lead to higher profits. However, if your needs are sporadic, might a less costly option suffice? Analyze your business model carefully.

Tips: Look for user reviews online. They can provide insights into real-world performance. Also, consider training. Proper operation can prevent costly mistakes. Remember, the best machine isn’t always the most expensive one. Evaluate your specific needs for optimal investment.