In the world of manufacturing, precision matters. A CNC cutting machine can transform designs into reality with incredible accuracy. These machines are vital for various industries, from automotive to woodworking. With advancements in technology, selecting the right CNC cutting machine is crucial for maximizing efficiency.

When exploring options for 2026, it's essential to consider factors like speed, software compatibility, and material versatility. Each machine offers unique features that can enhance productivity, but not every option suits every business. Reflecting on past choices can help avoid potential pitfalls.

While some machines boast superior capabilities, they may require a steep learning curve. Businesses must weigh the benefits against the challenges associated with implementation. This decision can define the success of your operations. Understanding these nuances will guide you toward making informed choices in your CNC cutting machine investment.

In 2026, CNC cutting machines continue to revolutionize industries. Precision and efficiency are more crucial than ever. According to a recent industry report, 65% of manufacturing processes now rely on CNC technology. This shift highlights how vital these machines are for maintaining competitiveness.

Many brands are leading the market with innovative designs. Estimates show the global CNC cutting machine market could reach $5 billion by 2026. Brands that adapt quickly to new technologies often gain market share. However, businesses must be cautious. Investing in cutting-edge machines without proper training can lead to inefficiencies. Many companies struggle with integration issues, often resulting in unexpected costs.

The demand for eco-friendly options is also rising. Reports indicate that 30% of consumers now prefer sustainable manufacturing practices. Some CNC machines struggle to meet these newer environmental standards. This gap can be problematic for brands aiming to attract eco-conscious clients. Regular assessments of machine performance and environmental impact will be integral to future success.

This chart illustrates the performance ratings of CNC cutting machines in 2026 across various dimensions including Precision, Speed, Efficiency, Durability, and Cost-effectiveness. The ratings reflect the industry's focus on enhancing these key attributes to optimize cutting operations.

When choosing a CNC cutting machine, precision is key. Look for features like accuracy and repeatability. These specifications directly impact the quality of your work. A machine with a high resolution will produce cleaner cuts and finer details. Pay attention to the spindle speed as well. The right speed can enhance the cutting process and material finish.

Tip: Consider the cutting area size. It should match your project needs. A small workspace with limited precision can lead to errors. Ensure the machine can handle various materials. This flexibility is crucial for different tasks.

Efficiency also depends on the machine's software. A user-friendly interface can save time and reduce mistakes. Look for machines that support advanced software solutions. These tools help streamline the workflow. However, keep in mind that complicated software might increase the learning curve.

Tip: Test the machine if possible. Many options come with demo units. This trial can reveal strengths and weaknesses. You may find that the machine isn’t as intuitive as it claims. Evaluating practical performance can guide a better purchase decision.

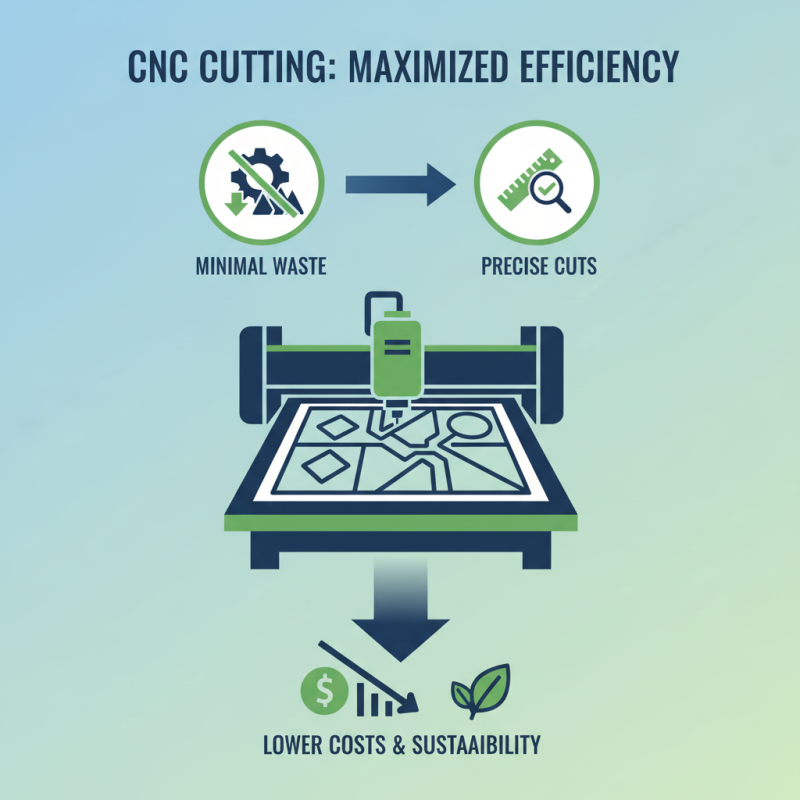

CNC cutting machines deliver unmatched efficiency in manufacturing. They minimize material waste by optimizing cutting paths. This reduces the amount of scrap produced, which is crucial for any production line. Machine operators can input precise dimensions, ensuring each cut is exact. The result? Less wasted material and lower costs.

However, achieving maximum efficiency isn't without challenges. Operators must regularly maintain equipment. Without proper care, machines can produce inaccurate cuts, leading to more waste. Sometimes the software needs updates to keep up with evolving materials. This might be overlooked, resulting in further inefficiencies.

Investing in quality CNC machines is essential, but training operators is equally important. Even the best machines are only as good as their users. Mistakes can happen. These issues highlight the importance of constant learning and adaptation in the ever-evolving manufacturing landscape.

The fast-paced world of CNC machining is evolving rapidly. Recent reports from industry experts indicate that the adoption of AI and machine learning technologies boosts precision by up to 30%. These advancements simplify complex processes, allowing manufacturers to enhance their workflow efficiency considerably. Innovations like adaptive control systems are changing how machines respond to various conditions.

With these changes come the need for continuous learning. It's crucial for operators to embrace new technologies. Regular training ensures that teams are well-prepared. A study shows that well-trained staff can decrease production time by as much as 20%. This readiness to adapt can make a significant difference in the long run.

Tips for enhancing performance include regularly updating software and firmware. Schedule routine maintenance to keep machinery operating at peak performance. Encourage feedback from operators on equipment usability. They often have insights that can optimize processes further. Embrace the idea that improvement is a journey, not a destination. Staying stagnant can lead to missed opportunities.

| Model | Type | Max Cutting Speed (mm/min) | Precision (mm) | Work Area (mm) | Power Consumption (kW) |

|---|---|---|---|---|---|

| Model A | Laser Cutting | 3000 | 0.05 | 1500 x 3000 | 5 |

| Model B | Plasma Cutting | 2500 | 0.1 | 2000 x 4000 | 7 |

| Model C | Waterjet Cutting | 1500 | 0.02 | 1800 x 3600 | 10 |

| Model D | CNC Router | 2000 | 0.1 | 1200 x 2400 | 3 |

| Model E | Oxy-fuel Cutting | 1800 | 0.2 | 3000 x 6000 | 6 |

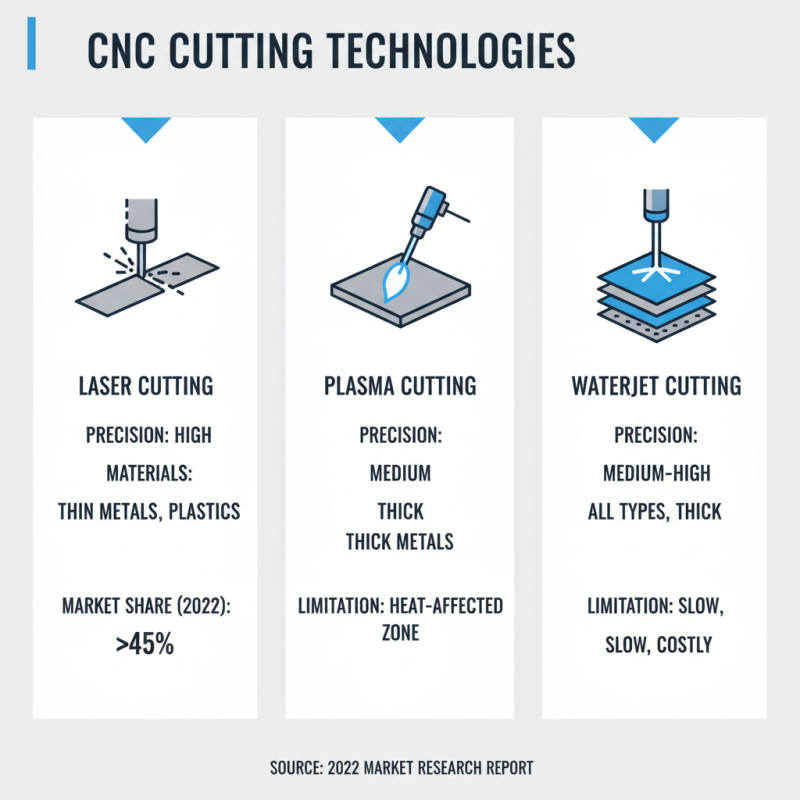

CNC cutting technologies include laser, plasma, and waterjet methods. Each method has unique capabilities, but also limitations. According to a recent market research report, laser cutting systems accounted for over 45% of the CNC cutting market in 2022 due to their precision. However, this method may not be suitable for thicker materials.

Plasma cutting is effective for metals. It offers high speed and lower operational costs. In fact, plasma cutting can be three to five times faster than traditional cutting methods. Yet, the cut quality varies significantly based on material thickness, which can be problematic. Industries relying on precise tolerances may struggle with these inconsistencies.

Waterjet cutting is advantageous for materials that can’t withstand high heat. This method delivers a fine edge without thermal distortion. However, it often requires more maintenance, which can pose operational challenges. A technical study revealed that waterjet systems can be twice as expensive to operate than plasma systems. Balancing these factors is critical for efficiency and effectiveness in CNC cutting applications.