In today's world of precision crafting, the Cnc Laser Cutter stands out as a game-changer. This machine allows creators to transform their ideas into reality with unparalleled accuracy and speed. Imagine cutting intricate designs on wood, acrylic, or metal with just a push of a button. The versatility of the Cnc Laser Cutter is remarkable, catering to a variety of projects and industries.

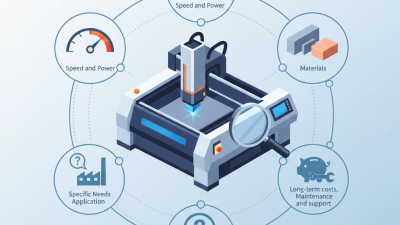

However, it's important to recognize that mastering this technology requires practice. Not every design will turn out perfect on the first try. Learning the ins and outs of settings, materials, and speeds can be a trial-and-error process. Yet, each mistake serves as a lesson, honing your skills and deepening your understanding.

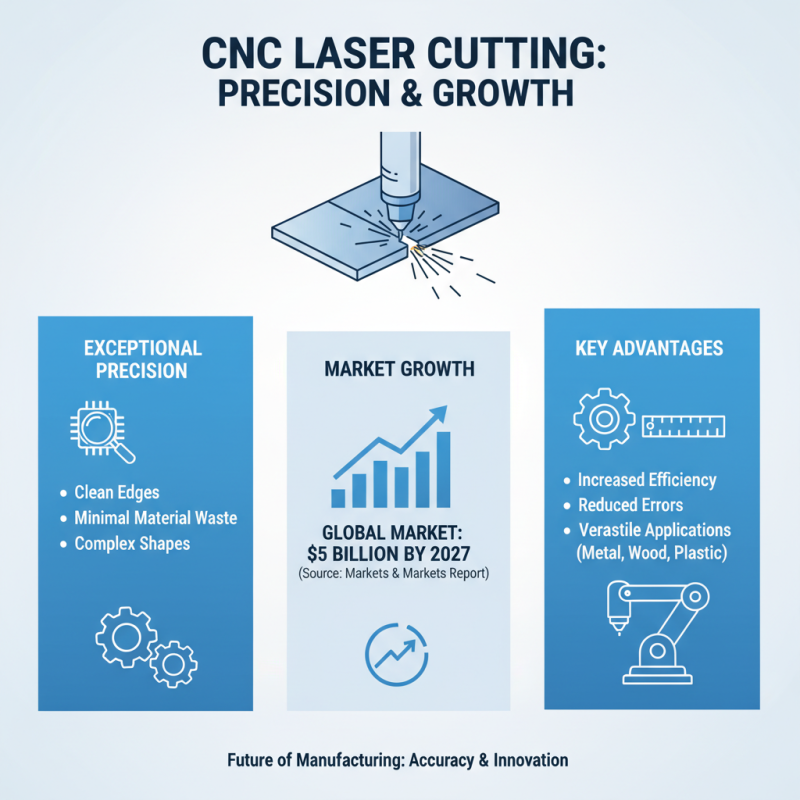

The benefits of using a Cnc Laser Cutter are substantial. Efficiency increases, and waste decreases as this machine uses precise cuts. Projects that once took hours can now be completed in minutes. As creators explore the capabilities of the Cnc Laser Cutter, they unlock new potential for innovation and artistry. Embracing this technology can elevate any project to new heights.

CNC laser cutting technology brings exceptional precision to various projects. According to a report by Markets and Markets, the global laser cutting machine market is expected to grow significantly, reaching $5 billion by 2027. This growth reflects the increasing demand for accuracy. Laser cutters create clean edges with minimal material waste, which is crucial for efficient production.

One major advantage of CNC laser cutting is its versatility. Whether cutting metal, wood, or plastics, the technology performs consistently. A study from the International Journal of Advanced Manufacturing Technology highlighted that laser cutting can achieve tolerances of up to ±0.01 mm. Such precision is vital in fields like aerospace and automotive manufacturing, where every detail counts.

However, relying solely on CNC laser technology may not suit every project. Some materials react poorly to heat. For instance, certain plastics may warp or discolor. Professionals need to consider material behavior to avoid costly mistakes. Balancing precision and material compatibility is essential for successful outcomes.

CNC laser cutters have revolutionized various industries by enhancing cost-efficiency. A key benefit is their ability to significantly reduce material waste. According to a 2021 report from the International Journal of Advanced Manufacturing Technology, laser cutting processes can achieve up to 95% material utilization, compared to traditional methods, which often leave behind a substantial amount of scrap.

This efficiency is crucial for businesses operating on tight margins. Companies can save on raw material costs and disposal fees. However, it is important to note that while this technology minimizes waste, improper programming or machine calibration can lead to inaccuracies and unintended waste. Inadequate training for operators might result in errors that negate cost savings.

Moreover, the investment in CNC laser cutting technology can be substantial. Initial costs include purchasing equipment and training staff. For some businesses, this may be a barrier. Yet, the long-term benefits typically outweigh these upfront expenses. Despite these challenges, the push for sustainability and efficiency makes it a worthy consideration for many projects.

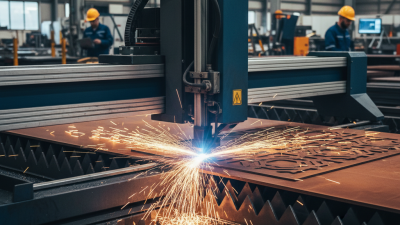

CNC laser systems offer remarkable versatility when it comes to materials. They can precisely cut and engrave various substances, from wood and acrylic to metals like stainless steel and aluminum. According to industry reports, over 70% of manufacturers use laser cutting technology for diverse projects due to its adaptability.

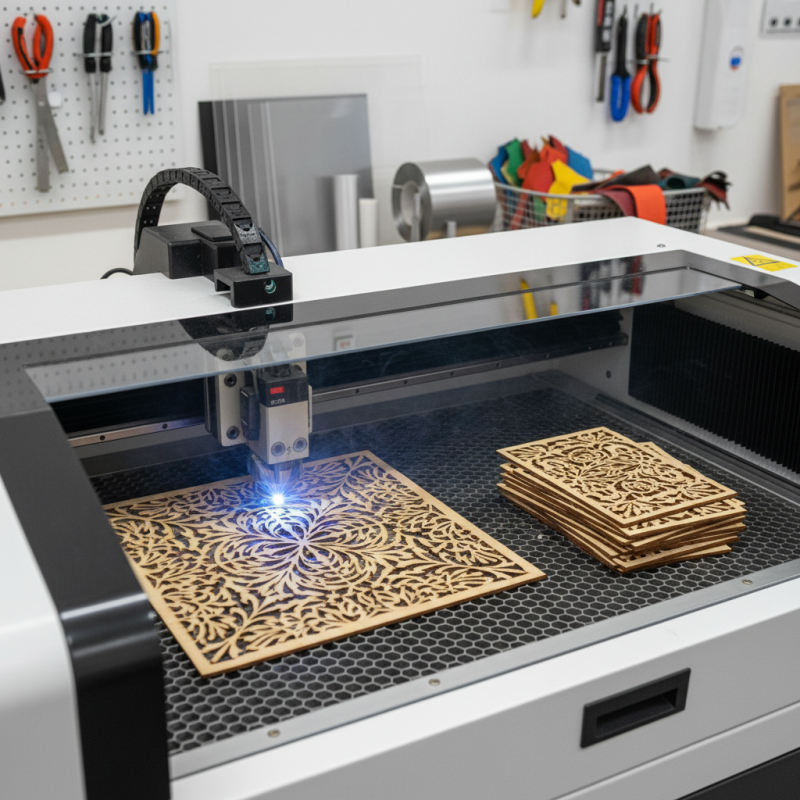

When working with wood, laser cutters create intricate designs quickly. They can cut shapes that would be nearly impossible with traditional tools. Acrylic, on the other hand, melts rather than burns, yielding smooth edges. However, challenges can arise with different thicknesses, leading to varying results.

Metals pose different challenges, but advancements have improved performance significantly. High-powered lasers can easily handle metals up to 20 mm thick. Yet, quality control remains vital. Burn marks and heat distortion require careful management. Each material demands specific settings, making experimentation essential for optimal outcomes. Many users find it a learning process, adjusting parameters through trial and error.

CNC laser cutters offer remarkable enhancements in design capabilities. They enable intricate patterns and designs that traditional cutting methods often struggle with. According to a report by IBISWorld, the laser cutting industry is expected to grow by 5.5% annually. This growth highlights the increasing demand for precision and creativity in various fields.

Designers can create more complex shapes and achieve finer details. The technology allows for quick adjustments during the design phase. As a result, modifications can be implemented on-the-fly, reducing turnaround times. However, this flexibility can sometimes lead to over-complicated designs that may not be practical.

Moreover, CNC laser cutters can work with a variety of materials, including wood, acrylic, and metals. A 2022 survey by Technavio indicated that 40% of users faced challenges in optimizing material choices. It’s essential to assess material compatibility with design objectives. Sometimes, not every material behaves as anticipated when cut by a laser. Therefore, testing and validation become crucial for successful outcomes.

Using a CNC laser cutter can significantly improve production speed and efficiency in various manufacturing processes. The precision of laser cutting allows for intricate designs with minimal material waste. This accuracy reduces the need for extensive post-processing, freeing up valuable resources. Companies can produce parts faster and with greater uniformity.

Tips: Regularly maintain your CNC laser cutter. This helps to ensure optimal performance and longevity. Updating the software can streamline processes like nesting.

Another advantage is the ability to tackle diverse materials. A CNC laser cutter can work on wood, metal, and plastics. Each material requires a different approach. Understanding these nuances can aid in maximizing efficiency. A few users find it challenging at first to adjust settings for different materials. This can slow down initial production until mastery is achieved.

Tips: Start with simple projects to get accustomed to machine settings. Gradually increase complexity as confidence grows. Test new materials with caution.