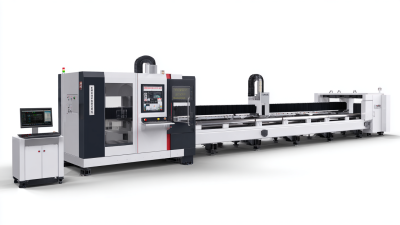

In today's fast-paced manufacturing environment, the adoption of advanced technologies is essential for businesses looking to enhance their productivity and efficiency. One such transformative technology is the Laser Cutting Machine, which has gained traction across various industries for its precision and versatility. According to Dr. Emily Carter, a renowned expert in laser technology, "The integration of a Laser Cutting Machine not only streamlines production processes but also opens new avenues for innovation in design and fabrication."

The benefits of employing a Laser Cutting Machine extend beyond mere accuracy; they encompass cost savings, improved speed, and the ability to work with a variety of materials. This technology allows for intricate designs that would be impossible to achieve through traditional cutting methods, making it a game-changer for companies aiming to stay competitive. With the right investment in a Laser Cutting Machine, businesses can not only enhance their operational capabilities but also elevate their overall product quality, positioning themselves favorably in an increasingly demanding market. As we delve into the top 10 benefits of using Laser Cutting Machines, it becomes clear that those who embrace this technology are not just keeping pace with industry developments; they are setting the stage for future success.

Laser cutting technology has revolutionized manufacturing processes across various industries by offering unmatched precision and accuracy. According to a report by MarketsandMarkets, the global laser cutting market is expected to reach $5.6 billion by 2025, driven significantly by its ability to provide intricate designs with minimal material wastage. This high level of precision not only enhances product quality but also leads to considerable cost savings in terms of both materials and labor.

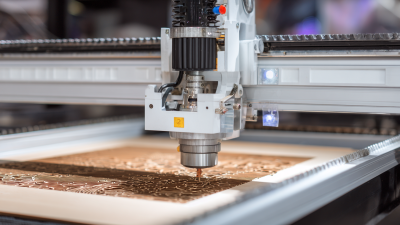

The advantages of precision in laser cutting are multi-faceted. For instance, the kerf width of laser cuts is typically around 0.1 mm to 0.2 mm, which is significantly narrower than traditional cutting methods. This precision allows for tighter tolerances and more complex geometries in the final products. Furthermore, the accuracy of laser cutting machines can reduce the need for extensive post-processing, thereby speeding up production timelines. According to the Fabricators & Manufacturers Association, employing laser cutting can increase production efficiency by up to 50%. With the integration of advanced automation and control systems, manufacturers can now achieve repeatable accuracy, making laser cutting a go-to solution for projects demanding high standards of precision.

Laser cutting machines have revolutionized the manufacturing landscape, particularly in optimizing production speed and efficiency. In a recent industry report, it was found that companies employing laser cutting technology have experienced up to a 30% reduction in production times compared to traditional cutting methods. This speed enhancement arises from the laser’s ability to precisely cut materials without the need for extensive pre-processing or subsequent finishing work, effectively streamlining operations and reducing lead times.

Furthermore, the precision of laser cutting machines translates directly into higher material yield and reduced waste. A study highlighted that organizations leveraging laser technology can achieve material utilization rates exceeding 85%, a significant improvement over conventional methods. This efficiency not only minimizes waste disposal costs but also contributes to a more sustainable manufacturing process. As companies face growing pressure to optimize their operations, the adoption of laser cutting machines stands out as a crucial step towards achieving both efficiency and environmental stewardship in production.

Laser cutting technology has revolutionized the manufacturing sector, providing businesses with unparalleled versatility in material processing. This advanced method can efficiently cut through a wide array of materials, including metals, plastics, wood, glass, and textiles. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach USD 5.41 billion by 2025, driven largely by the technology's ability to handle intricate designs and diverse materials with precision.

The capability to cut various materials not only enhances design flexibility but also allows for more innovative product development. For instance, in the automotive industry, laser cutting enables the production of complex shapes in lightweight metals such as aluminum and titanium, which are essential for improving fuel efficiency. Similarly, in the fashion and textiles sector, lasers can cut fabrics with high accuracy, allowing designers to experiment with unique patterns and styles without compromising on quality. Industry experts emphasize that the adaptability of laser cutting technology to various substrates and thicknesses significantly reduces the time and costs associated with product prototyping, making it an essential tool for businesses aiming to stay competitive in the market.

This chart illustrates the versatility of materials that can be cut using laser technology, showcasing its benefits for diverse industries.

Laser cutting machines have revolutionized manufacturing processes across various industries, significantly contributing to material waste reduction. Traditional cutting methods often produce substantial scrap material, leading to increased costs and environmental concerns. In contrast, laser cutting utilizes focused laser beams to cut materials with exceptional precision, minimizing the kerf—the width of the cut—thereby preserving valuable resources. According to a report by the International Journal of Advanced Manufacturing Technology, laser cutting technology can reduce material waste by up to 30% compared to conventional cutting methods.

Moreover, the adaptive nature of laser cutting allows businesses to optimize the layout of their designs on sheets, leading to a more efficient use of materials. Advanced software can calculate the most efficient nesting patterns, ensuring that every inch of the material is used effectively. A study by the Machining Science and Technology journal highlights that efficient nesting can lead to a further 15% reduction in material waste. The combination of precise cutting and optimized design layouts showcases the potential of laser cutting machines as not only a means to improve product quality but also a sustainable solution that aligns manufacturing practices with environmental responsibility.

| Benefit | Description | Estimated Waste Reduction (%) |

|---|---|---|

| Precision Cutting | Laser cutting provides high precision, reducing excess material removal. | 30 |

| Versatility | Can cut a variety of materials including metals, plastics, and wood. | 20 |

| Less Scrap Material | The focused laser beam minimizes kerf width, producing less scrap. | 25 |

| Reduced Setup Time | Quick adjustments and programming for different designs cut down production time. | 15 |

| Increased Production Speed | High-speed cutting allows for higher output without compromising quality. | 40 |

| Enhanced Safety | Laser cutting minimizes physical contact with materials, enhancing workplace safety. | 10 |

| Lower Energy Consumption | Efficient energy usage compared to traditional methods reduces overall costs. | 18 |

| Less Material Handling | Automation in laser cutting minimizes the need for manual handling of materials. | 12 |

| Quality Edges | Laser cutting produces smooth edges requiring less post-processing. | 22 |

| Customization | Easy to customize designs without the need for extensive tooling. | 5 |

Investing in a laser cutting machine can significantly enhance the cost-effectiveness of your operations in the long run. Unlike traditional cutting methods, laser cutting utilizes highly focused beams of light to cut through materials with precision and efficiency. This level of accuracy reduces material waste and ensures that you achieve the best possible yield from your raw materials. Additionally, the speed at which laser cutting operates means that production time is reduced, leading to lower labor costs and faster turnaround for orders.

Moreover, the maintenance costs associated with laser cutting machines tend to be lower than those for conventional cutting tools. Laser systems typically require less frequent replacements and have fewer moving parts, which translates into fewer breakdowns and repairs. As businesses strive for sustainable practices, the energy efficiency of laser cutting technology also plays a role in reducing overall operational expenses. By minimizing power consumption and maximizing output, companies can see a remarkable return on their investment over time, further solidifying the laser cutting machine's role as a key asset in cost-effective business operations.