In the evolving landscape of manufacturing, the precision of cutting techniques is paramount. Cnc Fiber Laser systems are at the forefront, revolutionizing how industries operate. Renowned expert Dr. Emily Carter once stated, “Precision in cutting is not just a goal, it’s a necessity in today’s market.”

Today, the demand for efficient and precise cutting solutions has increased. Cnc Fiber Laser technology provides a remarkable edge. It delivers high-quality cuts, minimizing material wastage. This technology is not without its challenges. For instance, the initial investment can be significant. Companies must also consider ongoing maintenance.

As we explore the 2026 Best Cnc Fiber Laser Systems, we must reflect on both advancements and limitations. How can industries adapt to this technology while addressing potential hurdles? The answers will shape the future of precision cutting.

CNC fiber laser systems have transformed precision cutting. In 2026, advancements are crucial for industries that rely on exact dimensions and clean edges. Engineers often face challenges in achieving consistent results. The quality of materials can dramatically affect the final output. Different metals react uniquely under laser cutting, making understanding these variations essential.

Precision cutting involves various factors. Beam quality, cutting speed, and focus play significant roles in the outcome. Users must experiment with settings to find the best balance. That can sometimes lead to frustration when results don’t meet expectations. Regular maintenance of the laser system is necessary. Neglecting this often leads to inefficiencies and unexpected costs.

Looking ahead, new technologies promise even better outcomes. Automation features are increasingly important, reducing human error and allowing for complex designs. Yet, not all innovations yield success on the first try. Each implementation requires careful evaluation and adjustments. The potential for mistakes and learning is always present in this evolving field.

The landscape of CNC fiber laser systems in 2026 emphasizes precision and efficiency. Key features include high cutting speed and superior beam quality. Data from industry reports show that systems can achieve speeds of up to 25 meters per minute. This rapid pace enhances production and reduces downtime. Meanwhile, beam quality impacts cutting thickness and precision. Systems with a higher-quality beam can cut through thicker materials with less distortion.

Adaptability is another crucial feature. The best systems offer versatility in handling various materials like steel, aluminum, and even titanium. However, adaptability comes with a caveat. Operators must be trained adequately to handle different settings and materials. A lack of training can lead to mistakes and compromised quality. Reports indicate that up to 30% of downtime can result from operator errors and insufficient calibration.

Automation in CNC fiber laser systems is also on the rise. Many leading systems now incorporate smart tech for real-time monitoring. This integration helps in predicting maintenance needs. Yet, reliance on automation can sometimes lead to complacency. Operators might overlook manual checks, risking equipment performance. A balanced approach combining automation and human oversight is essential for optimal results.

| Model | Cutting Speed (m/min) | Max Cutting Thickness (mm) | Laser Power (kW) | Precision (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 30 | 20 | 2 | 0.05 | 1500 |

| Model B | 35 | 15 | 3 | 0.03 | 1600 |

| Model C | 28 | 25 | 2.5 | 0.04 | 1450 |

| Model D | 40 | 10 | 4 | 0.02 | 1700 |

| Model E | 25 | 30 | 1.5 | 0.06 | 1400 |

The CNC fiber laser market is evolving rapidly, reflecting the demand for precision cutting in various industries. A recent report indicates that the global CNC fiber laser market is expected to reach $6 billion by 2027, growing at a CAGR of 12.8%. This growth highlights how essential precision cutting technology has become in manufacturing, especially in sectors like automotive and metal fabrication. However, with numerous systems available, choosing the right one can be daunting.

When comparing different CNC fiber laser systems, two critical factors are power efficiency and cut quality. Systems with higher power ratings often deliver faster cutting speeds. However, they may not always provide superior edge quality or lower operational costs. In some cases, systems with mid-range power settings can achieve excellent results while saving energy. Additionally, maintenance is a significant factor. Some systems require frequent servicing, which could lead to increased downtime. According to industry reports, an average laser cutter can incur maintenance costs of up to 10% of its purchase price annually. This presents a crucial reflection point for buyers: the initial savings on purchase may not outweigh the total cost of ownership.

Analyzing user reviews reveals common pain points, such as software compatibility and ease of use. Many operators express frustration when transitioning from older models to new systems. This suggests that while advancements in technology improve cutting precision, the learning curve can be a barrier. An effective system must not only excel in cutting capabilities but also be user-friendly. Ultimately, selecting a system requires careful consideration of these various elements, reflecting broader industry trends and specific operational needs.

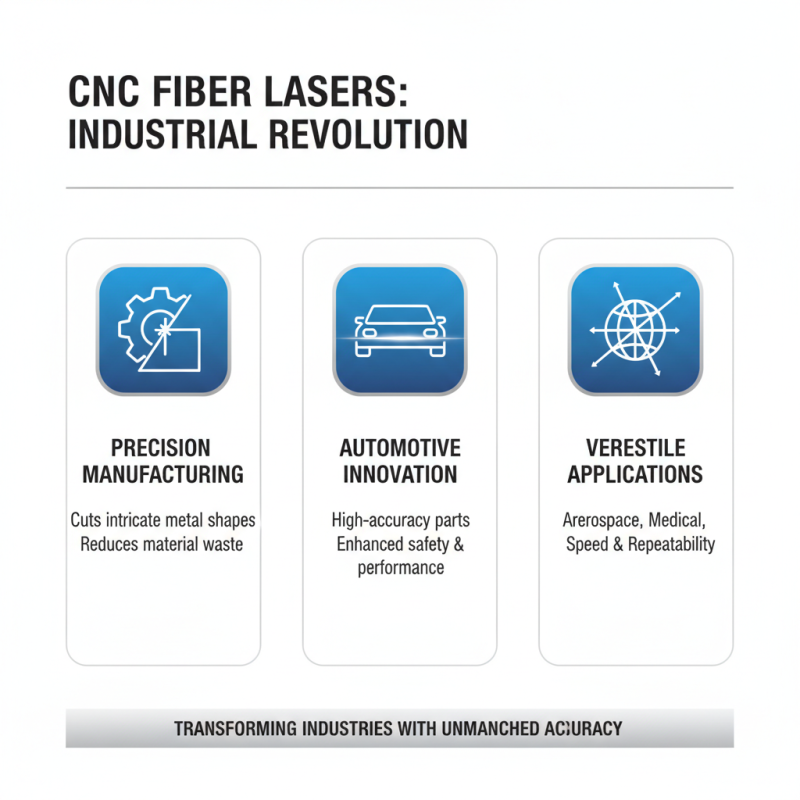

CNC fiber lasers are transforming various industries with their precision cutting capabilities. In manufacturing, these systems excel at cutting sheets of metal into intricate shapes. The automotive sector uses them to create parts that require high accuracy. This not only enhances performance but also improves safety features in vehicles.

In the aerospace industry, CNC fiber lasers play a crucial role. They are used to cut lightweight materials, such as aluminum and titanium. Precision is vital here, as even small errors can lead to serious safety concerns. When implementing these systems, companies need to pay attention to detail to avoid costly mistakes.

Tips: Regular maintenance of your CNC fiber laser system is essential. Check the calibration frequently. This helps maintain cutting quality. Additionally, use the right settings for different materials. Incorrect settings can lead to poor cuts and waste of resources. Always double-check your parameters before starting a new project.

As industries continue to advance, CNC fiber laser systems are becoming essential for precision cutting. The global market for these systems is expected to reach $6.21 billion by 2026, growing at a CAGR of 8.5%. This growth is driven by the increasing demand for high-quality cutting in various sectors such as automotive, aerospace, and metal fabrication.

Future trends show that automation and AI will play crucial roles in enhancing cutting precision. For instance, integrating smart technologies can optimize cutting parameters, leading to improved efficiency. Reports suggest that these innovations may reduce waste by up to 30%, a significant improvement for companies focused on sustainability. However, manufacturers must tread carefully. Adopting new technologies requires extensive training and adaptation, which can be costly and time-consuming.

Furthermore, the materials used in precision cutting are evolving. Advanced composites and exotic metals present both opportunities and challenges. While laser systems can handle these materials effectively, achieving optimal results often necessitates ongoing research and development. Companies must continuously evaluate their equipment and processes to stay competitive. The pursuit of excellence in cutting precision is an ongoing journey, punctuated by challenges that require reflection and adjustment.