In the ever-evolving landscape of manufacturing, the adoption of Laser CNC Machine for Metal is transforming how industries approach precision cutting. According to a recent report by the International Federation of Robotics, the demand for laser cutting technologies has surged, driven by the need for higher efficiency and reduced operational costs in metal fabrication. This surge is projected to grow by 12% annually, underscoring the technology's critical role in shaping the future of metalworking.

Industry expert Dr. Emily Carter, a leading authority in laser cutting technology, emphasizes the significance of this advancement: "The adoption of Laser CNC Machines for metal processing not only enhances accuracy but also streamlines production, enabling manufacturers to meet the ever-increasing demand for customized metal components." As we move into 2025, understanding the capabilities and features of the top Laser CNC Machines for Metal will be essential for businesses aiming to leverage this technology for competitive advantage.

This ultimate buying guide aims to provide insight into the best Laser CNC Machines for Metal cutting currently available, considering factors such as precision, speed, and versatility. By doing so, it equips buyers with the knowledge needed to make informed choices tailored to their specific operational needs.

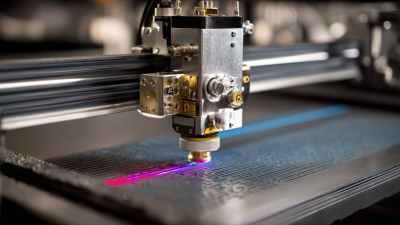

In 2025, the landscape of laser CNC machines for metal cutting is poised for remarkable advancements, driven by innovations in technology and increasing demand for precision manufacturing. These machines utilize high-powered lasers to achieve intricate cuts and shapes in various metals, making them indispensable in industries ranging from aerospace to automotive. With features like automated settings and improved software interfaces, modern laser CNC machines prioritize user-friendliness while maintaining exceptional cutting speeds and accuracy.

Moreover, the emphasis on energy efficiency and environmental sustainability is shaping the design of laser CNC machines. In 2025, manufacturers are likely to emphasize reduced energy consumption, utilizing cutting-edge technologies that not only enhance performance but also adhere to eco-friendly standards. This shift reflects a growing awareness within the industry regarding the importance of minimizing the carbon footprint associated with metal fabrication processes. As a result, the future of laser CNC machines appears bright, promising enhanced capabilities and broader applications across various sectors.

When selecting a laser CNC machine for metal cutting, it's crucial to consider several key specifications to ensure it meets your operational needs. One of the primary factors is the laser power, measured in watts. Higher wattage allows for cutting through thicker materials at faster speeds, making it ideal for industrial applications where efficiency is paramount. Additionally, the type of laser—CO2 or fiber—plays a significant role in determining the machine's effectiveness on different metals, with fiber lasers typically being more effective for reflective materials like aluminum and copper.

Another important consideration is the cutting area. The size of the workpiece you aim to process should dictate the required dimensions of the machine's bed. A larger cutting area allows for more versatility in handling different projects without the need for frequent repositioning. Moreover, advanced features such as autofocus systems, motion control capabilities, and software compatibility can greatly enhance the machine's performance and ease of use. Evaluating these specifications will help ensure that you choose a laser CNC machine that is both efficient and suitable for your specific metal cutting requirements.

The landscape of laser CNC technology is evolving rapidly, driven by innovations that enhance precision and efficiency in metal fabrication. As industries embrace automation and advanced manufacturing techniques, laser CNC machines have become essential tools. These machines offer unmatched precision in cutting various metals, thereby meeting the growing demand for complex designs and intricate details in production processes. The integration of software solutions and IoT capabilities further boosts productivity, allowing for real-time monitoring and adjustments during operations.

Market trends indicate a significant shift towards sustainability and energy efficiency in the design of laser CNC machines. Manufacturers are increasingly focused on developing equipment that not only performs efficiently but also minimizes environmental impact. This includes the use of advanced cooling systems and energy-efficient lasers that reduce power consumption. Additionally, the rise of smart factories and Industry 4.0 is influencing the adoption of more sophisticated laser CNC solutions, enabling seamless integration with other manufacturing technologies and streamlining production workflows. As businesses prioritize these trends, the future of metal fabrication looks set to become more innovative and resource-conscious.

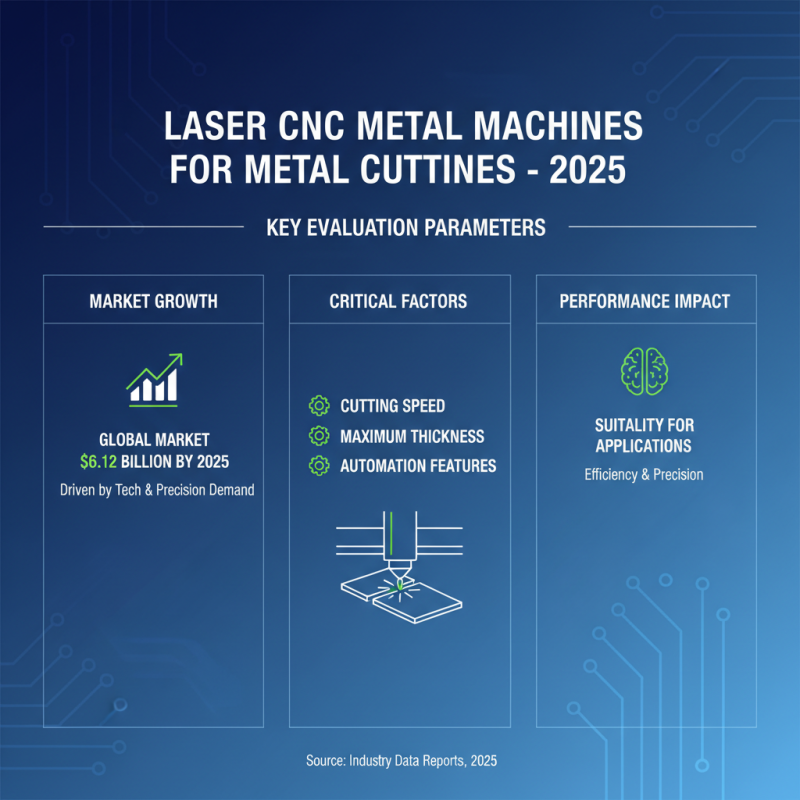

When evaluating the leading laser CNC machines for metal cutting in 2025, it is essential to consider several key parameters that affect performance and efficiency. Recent industry data reports indicate that the global laser cutting market is anticipated to reach $6.12 billion by 2025, driven by advancements in technology and increasing demand for precision cutting in various sectors. The comparative analysis of the best machines reveals that factors such as cutting speed, maximum thickness capacity, and automation features play a significant role in determining a machine's suitability for specific applications.

In terms of cutting speed, top-tier laser CNC machines can achieve rates exceeding 60 meters per minute, which significantly enhances productivity in manufacturing environments. Additionally, the ability to process thicker materials is becoming increasingly vital; machines capable of cutting metals up to 25 mm thick are gaining popularity in industries like aerospace and automotive. Automation features, including adaptive technology that optimizes cutting parameters in real time, have also emerged as a deciding factor, allowing operators to minimize downtime and enhance overall operational efficiency. This detailed comparative analysis aids buyers in making informed decisions tailored to their specific manufacturing needs, ensuring they choose a machine that aligns with the demands of modern metal cutting applications.

As industries increasingly adopt advanced manufacturing technologies, laser CNC machines stand out as a critical investment for metal cutting applications in 2025. The cost-benefit evaluation of investing in laser CNC technology reveals significant advantages, particularly when it comes to operational efficiency and precision. According to a recent market analysis by Research and Markets, the global laser cutting machine market is projected to grow at a compound annual growth rate (CAGR) of 7.4% between 2022 and 2026, indicating a robust interest and reliance on laser technology in various sectors.

One crucial aspect of the cost-benefit evaluation lies in the long-term savings associated with laser CNC machines. These machines offer reduced waste material and lower energy consumption compared to traditional cutting methods. The Fabricators & Manufacturers Association (FMA) reported that businesses using laser cutting technology could see a decrease in material waste by up to 30%, leading to significant cost savings over time. Additionally, laser CNC systems provide higher cutting speeds and improved accuracy, which can enhance productivity levels and minimize labor costs. As such, the initial investment in laser CNC technology is often recouped within a few years through increased output and reduced operational costs.

Moreover, ongoing advancements in laser technology further justify the investment. Enhanced features such as automation and integrated software solutions are streamlining workflows and boosting overall efficiency. According to a 2021 study by Deloitte, companies implementing automated laser cutting solutions can achieve production efficiency improvements of up to 40%. These technological advancements not only fortify a company's competitive edge but also provide a solid return on investment, making laser CNC machines an essential asset for businesses aiming to thrive in the evolving manufacturing landscape of 2025.