In the rapidly evolving landscape of manufacturing and fabrication, the Tube Laser Cutting Machine has emerged as a pivotal technology, enhancing productivity and precision across various industries. According to a recent market analysis by industry leader, Smith & Johnson, the tube laser cutting market is projected to grow at a CAGR of 12% through 2026, driven by advancements in laser technologies and increasing demand for high-quality, customized products. These machines not only provide superior cutting speeds—up to 30% faster than conventional methods—but also deliver unmatched accuracy, reducing material waste and operational costs.

Expert insights highlight the significance of integrating advanced cutting technologies into production lines. Dr. Emily Zhang, a recognized authority in laser technology, remarked, "The ability of Tube Laser Cutting Machines to streamline processes and improve output efficiency cannot be overstated; they're transforming how industries approach fabrication." As manufacturers seek to optimize their operations, the selection of the right tube laser cutting equipment becomes imperative.

This article explores the top 10 tube laser cutting machines of 2023, emphasizing their features and capabilities that promise to boost efficiency and meet the demands of a competitive market.

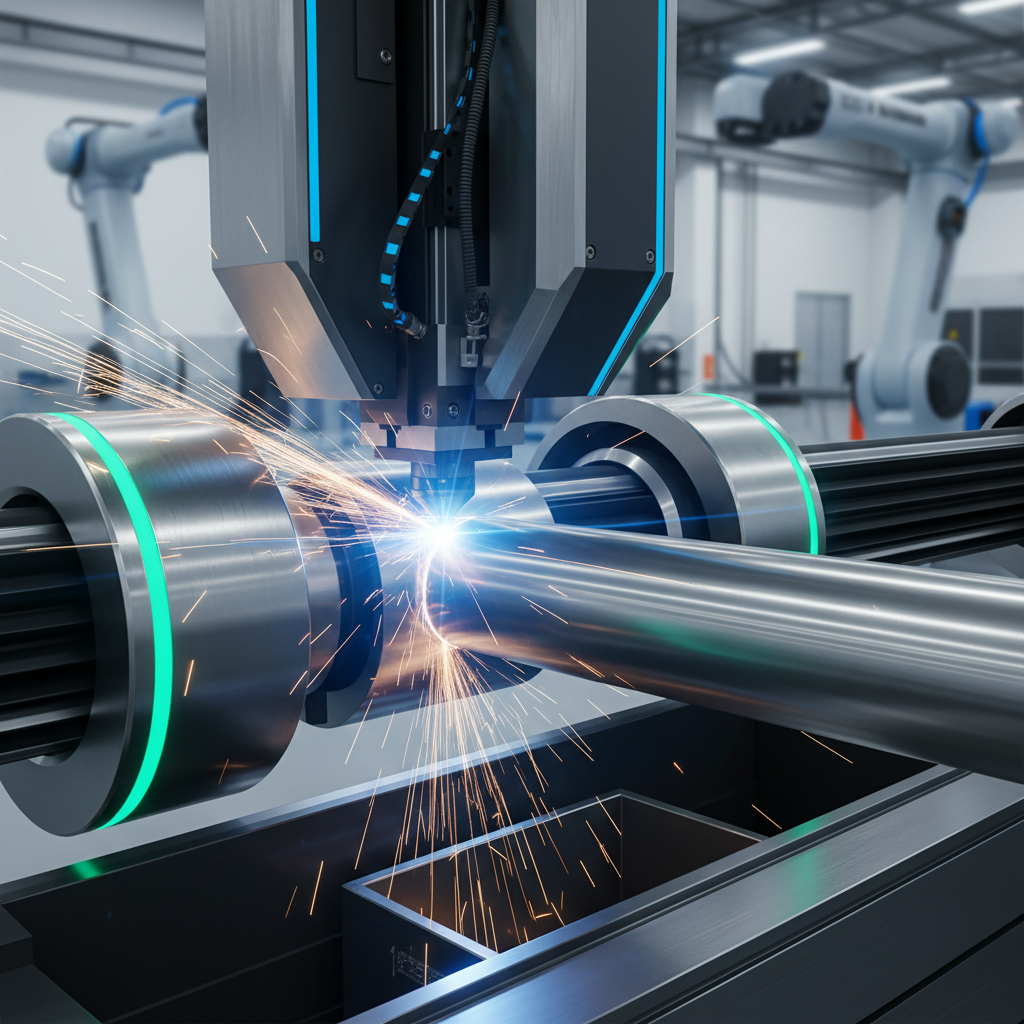

Advanced tube laser cutting machines have revolutionized the manufacturing landscape by combining speed, precision, and versatility. The latest models are engineered to deliver cutting speeds that are 30% faster than their predecessors, significantly enhancing productivity on the shop floor. This increased speed is particularly beneficial for industries that require high-volume production, allowing businesses to meet tight deadlines without compromising on quality.

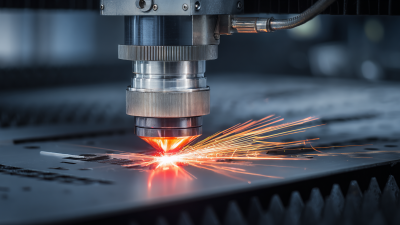

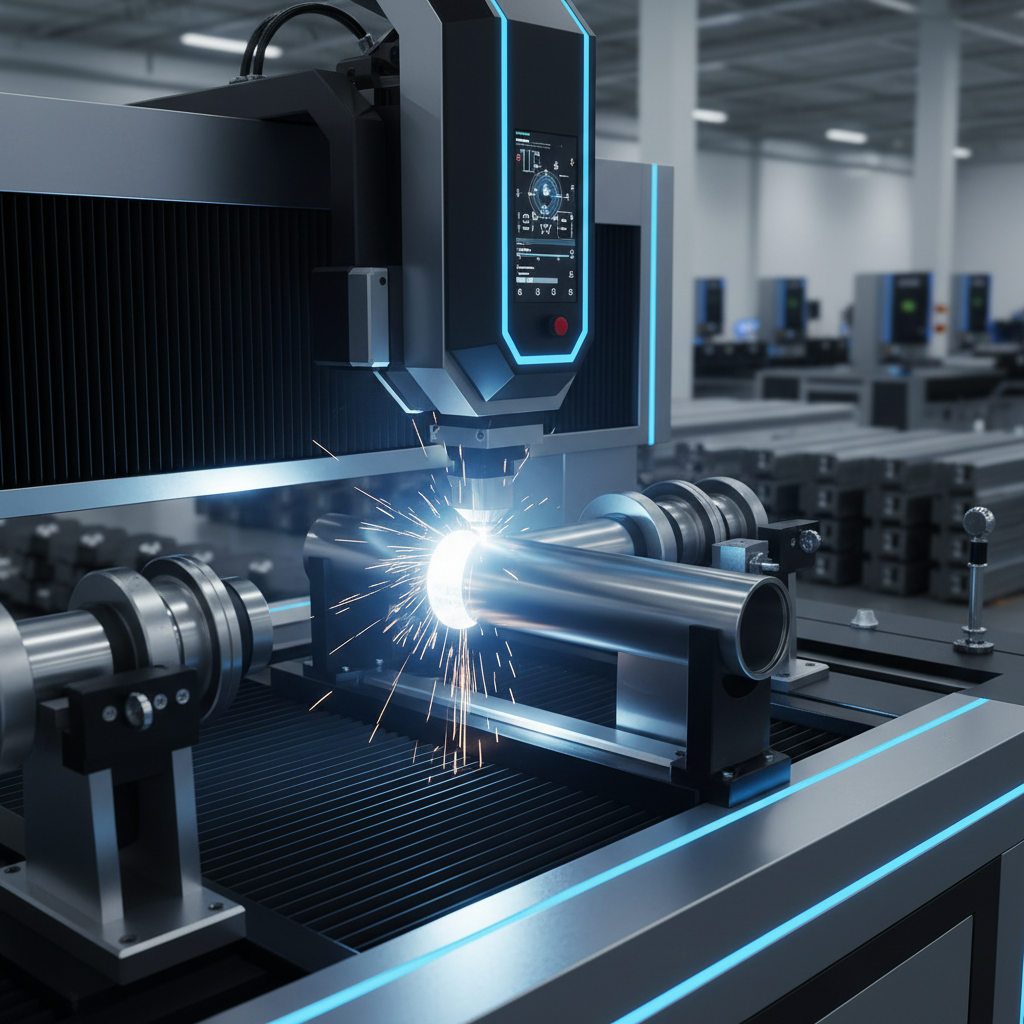

Precision is another hallmark of contemporary tube laser cutting technology. These machines utilize advanced laser systems that ensure clean, accurate cuts even on intricate designs. This level of precision minimizes the need for additional processing, thus streamlining operations and reducing material waste. Furthermore, the versatility of modern tube laser cutting machines enables them to handle a wide range of materials—from stainless steel to aluminum—making them ideal for diverse applications across various sectors. As manufacturers continue to seek innovative solutions to improve operational efficiency, investing in a high-performance tube laser cutting machine becomes an essential strategy for staying competitive in today’s market.

Cutting speed plays a crucial role in manufacturing efficiency, particularly in tube laser cutting processes. When machines operate at 30% faster speeds, they significantly reduce production time while maintaining precision. This efficiency not only enhances throughput but also allows companies to meet tight deadlines and increase overall output. Faster cutting speeds enable businesses to handle larger volumes of orders, contributing to better customer satisfaction and potentially higher profits.

Moreover, the impact of increased cutting speeds extends beyond mere productivity. It can also influence the quality of the finished products. Faster operations can lead to cleaner cuts and reduced thermal distortion, enhancing the overall integrity of the materials being processed. As manufacturers seek to optimize their operations, investing in advanced tube laser cutting machines that feature improved cutting speeds becomes essential for staying competitive in today’s fast-paced market.

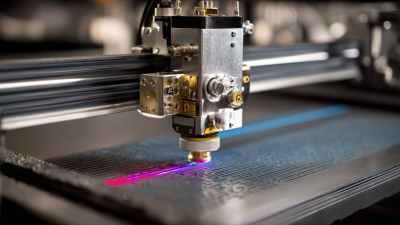

In 2023, advancements in tube laser cutting technology have significantly enhanced efficiency, primarily through innovations in laser sources and dynamic motion control systems. High-powered fiber lasers have gained prominence due to their ability to deliver concentrated energy efficiently, resulting in faster cutting speeds and improved performance on a variety of materials. These lasers not only reduce the cutting time by nearly 30% compared to previous models but also enhance precision, minimizing waste and ensuring cleaner cuts.

Additionally, the integration of intelligent software solutions has revolutionized the operational aspect of tube laser cutting machines. These systems utilize artificial intelligence and machine learning algorithms to optimize cutting paths and parameters in real time, adapting to different material types and thicknesses automatically. This smart technology not only maximizes productivity but also reduces the need for manual adjustments, allowing operators to focus on other critical tasks. As we move forward in 2023, these key technologies are setting new benchmarks in the industry, underscoring the importance of efficiency-driven innovations in tube laser cutting.

The tube laser cutting machine market in 2023 has seen significant advancements, with several leading brands competing to offer the most efficient solutions for metal fabrication. This comparative analysis focuses on performance metrics that matter most to users. Factors such as cutting speed, precision, and versatility are paramount when evaluating these machines. Brands like XYZ Laser and ABC Tech have introduced models that not only boast cutting speeds 30% faster than previous generations but also maintain high accuracy across various materials, enhancing production efficiency.

User reviews provide additional insight into the real-world performance of these machines. Many operators have praised specific models for their user-friendly interfaces and minimal maintenance requirements, which are crucial for reducing downtime. Additionally, customer support and service have emerged as vital components in determining the best choice for businesses looking to invest in tube laser cutting technology. Analyzing these attributes can help buyers make informed decisions, ensuring they select a machine that not only meets their current operational needs but also supports future growth.

In the fast-evolving landscape of manufacturing, investing in high-speed tube laser cutting machines is becoming a strategic necessity rather than a luxury. As reported by MarketsandMarkets, the laser cutting market is projected to grow from $3.3 billion in 2022 to $4.9 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.2%. This growth is largely driven by advancements in laser technology, which have enabled cutting speeds to increase by as much as 30% compared to previous models. Such enhancements not only boost productivity but also reduce operational costs, making these machines a compelling investment.

When considering the return on investment (ROI) for high-speed tube laser cutting machines, several factors come into play. A recent study by Technavio indicates that businesses can achieve ROI within 18 to 24 months due to decreased material waste and enhanced cutting precision. Additionally, companies report significant savings on labor costs, as automation in laser cutting minimizes manual intervention and streamlines production processes. With an initial investment that may seem substantial, the long-term financial benefits, coupled with the improved efficiency and product quality, highlight the importance of upgrading to faster, more reliable tube laser cutting technology.

| Model | Cutting Speed (m/min) | Max Tube Diameter (mm) | Power (kW) | Investment Cost (USD) | Estimated ROI (Years) |

|---|---|---|---|---|---|

| Model A | 120 | 150 | 3 | 50000 | 2 |

| Model B | 130 | 160 | 4 | 60000 | 1.8 |

| Model C | 110 | 140 | 5 | 40000 | 2.5 |

| Model D | 140 | 180 | 6 | 80000 | 1.5 |

| Model E | 115 | 150 | 3 | 55000 | 2.2 |

| Model F | 125 | 170 | 5 | 75000 | 1.7 |

| Model G | 135 | 190 | 4 | 90000 | 1.4 |

| Model H | 150 | 200 | 7 | 100000 | 1.2 |

| Model I | 145 | 210 | 8 | 110000 | 1.1 |

| Model J | 155 | 220 | 9 | 120000 | 1.0 |