In the realm of precision metal fabrication, the ability to cut tubes with accuracy and efficiency is paramount. The demand for reliable Tube Cutting Machines has surged, driven by advancements in manufacturing technologies and the increasing complexity of metal fabrication projects. According to a report by MarketsandMarkets, the global market for tube cutting machines is projected to reach over $1 billion by 2025, reflecting a compound annual growth rate (CAGR) of approximately 5% from 2020 to 2025. This growth can be attributed to the expanding applications of tube cutting in various industries, including automotive, aerospace, and construction.

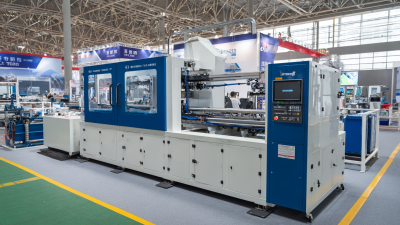

As we delve into the top 10 Tube Cutting Machines of 2023, it becomes evident that these machines are not just tools; they embody the innovation that is reshaping the fabrication landscape. Modern tube cutting technologies offer enhanced precision, reduced waste, and increased productivity. For instance, the integration of automation and advanced cutting techniques is enabling manufacturers to meet stringent quality standards while simultaneously lowering operational costs. This overview aims to highlight the most effective solutions available today, ensuring that professionals in the field can make informed decisions when selecting the right equipment for their cutting needs.

When selecting a tube cutting machine for precision metal fabrication, several key considerations come into play. Firstly, the type of material you will be cutting is crucial. Different machines are designed to handle various metals and thicknesses. Understanding the specifications of the material, including tensile strength and composition, will help ensure that you choose a machine capable of producing clean, accurate cuts.

Additionally, the cutting method is an essential factor to consider. Machines may employ techniques such as laser cutting, plasma cutting, or saw cutting. Each method has its advantages, depending on the desired precision, speed, and overall finish. It’s vital to assess the technology that best meets your project requirements while considering factors like operational costs, maintenance, and the skill level of your operators.

**Tips:** Always assess the machine's cutting speed and efficiency, as this can significantly impact your production timeline. Moreover, consider the machine's versatility for future projects; a multifunctional tool can save you time and resources. Finally, don't overlook the importance of customer support and availability of spare parts, as these factors can affect your long-term satisfaction and machine uptime.

| Model | Cutting Method | Max Tube Diameter (inches) | Cutting Speed (in/min) | Power Supply (V) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | Laser | 6 | 60 | 220 | 500 |

| Model B | Plasma | 8 | 50 | 240 | 600 |

| Model C | Saw | 4 | 40 | 110 | 450 |

| Model D | Water Jet | 10 | 30 | 380 | 700 |

| Model E | Oxy-Fuel | 12 | 25 | 220 | 800 |

| Model F | Laser | 5 | 70 | 240 | 550 |

| Model G | Plasma | 7 | 55 | 200 | 650 |

| Model H | Saw | 3 | 20 | 110 | 400 |

| Model I | Water Jet | 9 | 35 | 380 | 750 |

| Model J | Oxy-Fuel | 11 | 28 | 220 | 800 |

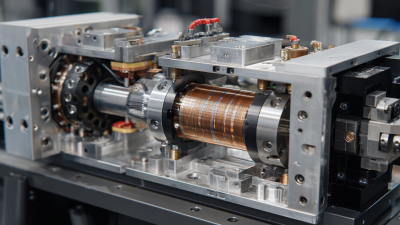

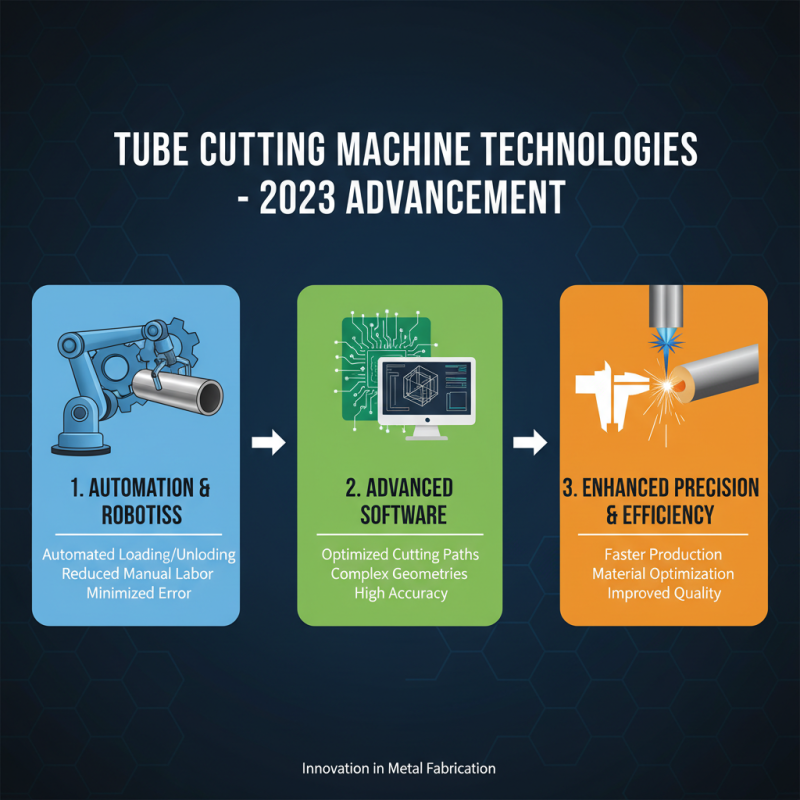

In 2023, tube cutting machine technologies have advanced significantly, incorporating innovative features that enhance precision and efficiency in metal fabrication. One of the most notable trends is the increased integration of automation and robotics. These systems enable automated loading and unloading of materials, significantly reducing manual labor and minimizing the risk of human error. Additionally, advanced software solutions offer improved cutting path optimization, allowing for more complex geometries to be executed with high accuracy.

Another major development is the enhancement of cutting methods, such as laser, plasma, and waterjet technology. These processes provide clean cuts with minimal thermal distortion, which is crucial for ensuring the integrity of the metal being processed. Furthermore, the incorporation of smart sensors and IoT applications into tube cutting machines allows for real-time monitoring and data collection, leading to predictive maintenance and less downtime. As a result, manufacturers can achieve better productivity and maintain superior quality in their operations, reflecting a growing trend towards smart manufacturing solutions in the metal fabrication industry.

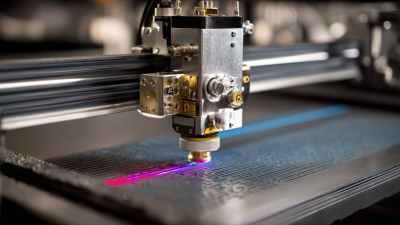

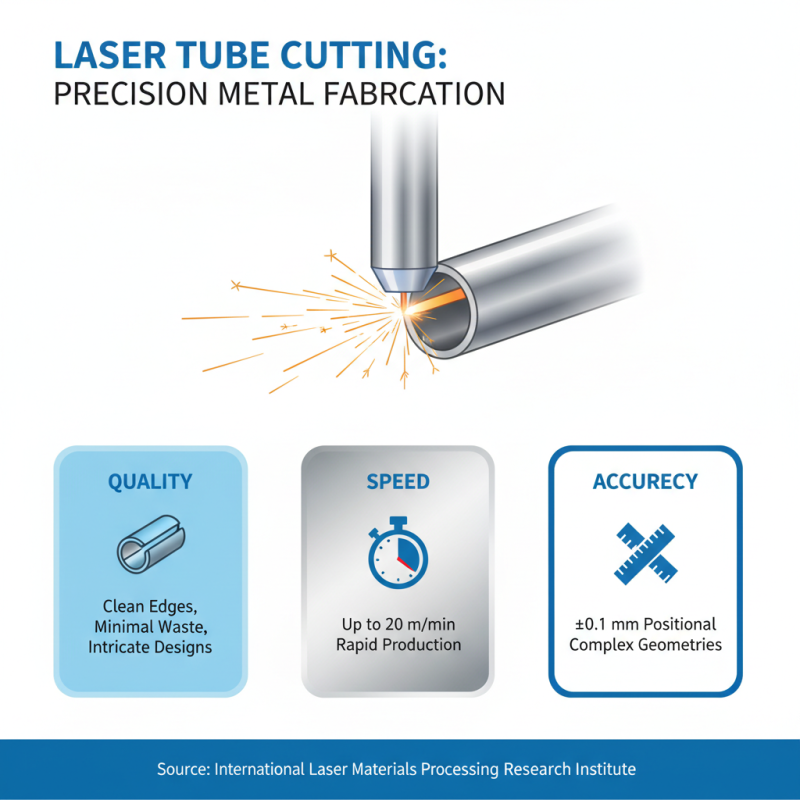

When it comes to tube cutting in precision metal fabrication, the choice of cutting method significantly influences the quality, speed, and cost of production. Laser cutting has emerged as a leading technology due to its ability to provide clean edges and intricate designs with minimal material waste. According to a report by the International Laser Materials Processing Research Institute, laser cutting can achieve a cutting speed of up to 20 meters per minute, with a positional accuracy of ±0.1 mm, making it ideal for complex geometries often required in high-precision applications.

In comparison, plasma cutting serves as a robust alternative, especially for thicker materials. It operates by using an active plasma stream to melt and expel metal, resulting in a rougher edge finish compared to laser cutting. A survey conducted by the Fabricators & Manufacturers Association indicates that plasma cutting can handle materials up to 50 mm thick, making it a popular choice for heavy-duty applications like construction and shipbuilding. The speed of plasma cutting can surpass that of laser cutting on thicker materials, thus providing a cost-effective solution when precision is less critical.

Waterjet cutting is another viable method, known for its versatility and ability to cut through a wide range of materials without introducing thermal distortion. According to the Waterjet Technology Association, this method can cut materials up to 300 mm thick with an accuracy of ±0.5 mm, making it suitable for applications where material integrity is paramount. Additionally, waterjet cutting is environmentally friendly, as it does not produce hazardous fumes or solid waste, making it an attractive choice for companies looking to maintain sustainable practices in their manufacturing processes.

When selecting precision tube cutting machines for metal fabrication, certain key features should not be overlooked. Firstly, the cutting accuracy is paramount. According to a report by the Fabricators and Manufacturers Association, machines with a precision rate of ±0.2 mm are preferred in high-stakes settings, ensuring tighter tolerances and superior quality. Additionally, the ability to handle various material types—such as stainless steel, aluminum, and carbon steel—expands operational flexibility, making the machine more versatile for diverse applications.

It's also essential to consider the operational speed of the machine. Recent industry surveys indicate that machines capable of cutting 30 meters per minute without compromising precision significantly enhance productivity. Moreover, technology integration, such as CNC capabilities, has become vital. CNC machines allow for automated, programmable cuts, increasing efficiency and minimizing human error.

Tips: When evaluating options, ensure the machine features customizable cutting settings for different tube diameters and wall thicknesses. Another tip is to look for machines equipped with onboard software for real-time monitoring and diagnostics to minimize downtime during production.

When it comes to precision metal fabrication, the choice of tube cutting machines plays a crucial role in achieving optimal results. According to a recent industry report by MarketsandMarkets, the global market for tube cutting machines is expected to grow at a CAGR of 6.5% from 2023 to 2028, driven by advancements in automation and demand for high-precision components across various industries. The right tube cutting machine can enhance production efficiency, reduce waste, and improve the overall quality of fabricated parts.

In 2023, the top tube cutting machines feature advanced technologies such as laser cutting, plasma cutting, and abrasive water jet cutting. These machines offer unparalleled precision, capable of achieving tolerances as tight as ±0.1 mm, which is critical in sectors like aerospace, automotive, and medical device manufacturing. An analysis from Technavio highlights that companies investing in automated tube cutting solutions are reporting significant reductions in cycle time, improving operational efficiency by up to 30%. With the ongoing trends towards digitalization and smart manufacturing, the adoption of these advanced machines is becoming increasingly integral to maintaining competitive advantage in the metal fabrication market.