Successful Metal Laser Cutting requires careful consideration and planning. This process involves precision and the right techniques to achieve optimal results. Understanding the intricacies of laser cutting is essential to avoid common pitfalls.

While the technology is advanced, mistakes can still happen. Many operators underestimate the importance of setup. Small errors in alignment can lead to wasted materials and time. Inadequate training can create challenges that are hard to address.

Attention to detail can significantly enhance the cutting process. Regular maintenance of equipment is crucial for reliable performance. Operators should frequently assess their strategies and outcomes. Reflecting on past projects can uncover valuable insights. By focusing on continuous improvement, you can elevate your Metal Laser Cutting success to new heights.

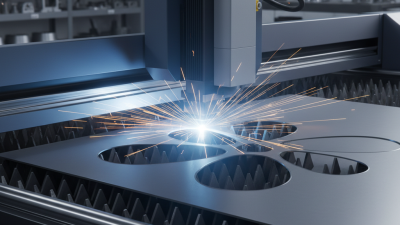

Metal laser cutting is a precise technology used in various industries. Understanding the key concepts behind this technique is vital for success. The process utilizes focused laser beams to cut through metal with exceptional accuracy. According to a recent industry report, the global metal laser cutting market is expected to reach over $5 billion by 2025, highlighting its growing importance.

Techniques such as fiber laser cutting and CO2 laser cutting are popular choices. Fiber lasers offer higher energy efficiency and faster cutting speeds. Meanwhile, CO2 lasers are known for their versatility, handling thicker materials well. A staggering 60% of manufacturers report efficiency gains of up to 30% when switching to laser cutting. However, not every application benefits equally from these methods. It's crucial to evaluate materials and thicknesses to ensure optimal results.

Proper setup and maintenance are often overlooked. Inadequate focus or poor lens quality can lead to subpar cuts. This can result in wasted material and increased costs. Regular inspections and adjustments are essential in maintaining equipment performance. Continuous learning about the latest advancements in laser technology can help mitigate common pitfalls. As laser cutting evolves, staying informed becomes just as crucial as mastering the fundamental techniques.

When engaging in metal laser cutting, having the right equipment is crucial for achieving optimal performance. High-quality laser cutters are designed to handle various thicknesses and materials. Data from a recent industry report shows that machines equipped with higher wattage provide better cutting speeds and precision. For instance, a 3000W laser cutter can cut through metals up to 25mm thick, while lower wattage options struggle with thicker materials.

Additionally, the choice of optics plays a significant role. Using high-grade lenses enhances beam quality, which directly impacts cutting accuracy. Poor optics can lead to asymmetrical cut edges or warp in the metal. Maintenance of the optics cannot be overlooked. Regular cleaning and inspections can prevent costly errors and downtime, as reports indicate that equipment failure often stems from neglecting this area.

Other essential equipment includes cooling systems and exhaust fans. Cooling systems maintain optimal temperatures during cutting operations. Poor temperature management can result in thermal distortion of the materials. Similarly, an efficient exhaust system is necessary to remove fumes and debris. Without proper airflow, particles can settle back onto the cutting surface, causing imperfections and compromising quality. The industry emphasizes the need for regular assessment of these systems to ensure consistent performance.

| Equipment | Optimal Settings | Material Thickness (mm) | Speed (mm/min) | Power (%) |

|---|---|---|---|---|

| Fiber Laser Cutter | Focused Beam | 1.0 | 1000 | 80% |

| CO2 Laser Cutter | Fast Cutting Mode | 2.0 | 800 | 70% |

| YAG Laser Cutter | High Precision | 3.0 | 600 | 85% |

| Plasma Cutter | Standard Mode | 5.0 | 400 | 100% |

Material selection plays a crucial role in metal laser cutting. The type of metal can significantly impact cutting quality and efficiency. Steel, aluminum, and brass each behave differently under the laser. According to industry reports, choosing the right materials can improve cutting speeds by up to 30%.

Using thicker sheets might seem advantageous, but they can lead to higher energy consumption and longer cycle times. For instance, cutting stainless steel requires precise attention. One study noted that cutting stainless steel with a laser increased the kerf width by 15% when the thickness exceeded 5mm.

It’s essential to consider surface finish and alloy composition too. Rougher surfaces can cause blowouts during cutting, leading to wasted materials. One expert emphasizes that poor material choices often result in increased wear on the laser head. It’s critical to test various materials and settings to find the optimal combination. Each project may require different considerations, adding layers of complexity to the process.

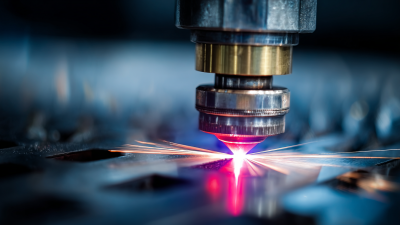

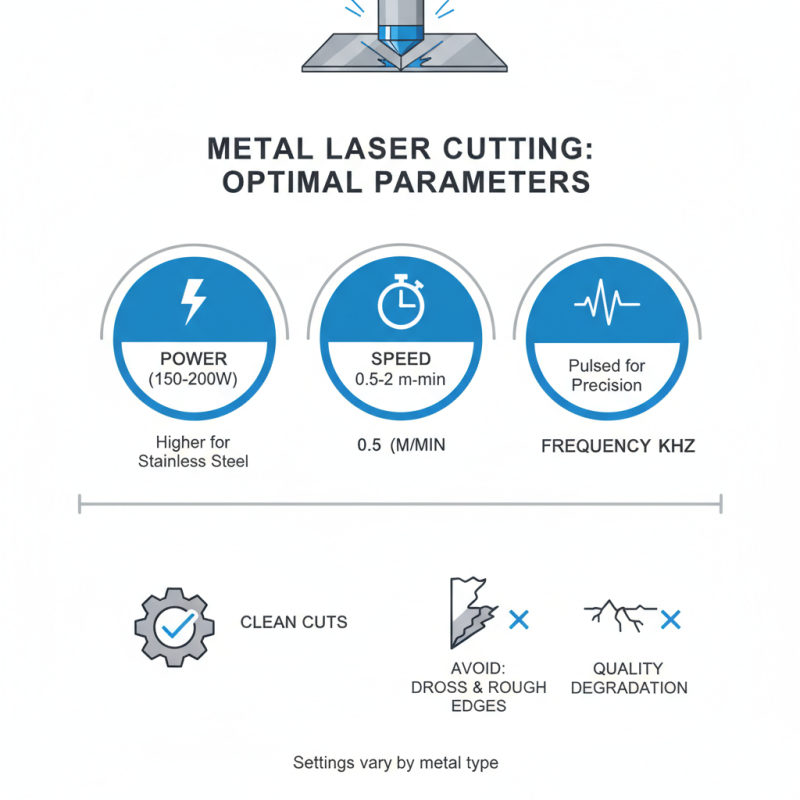

When it comes to metal laser cutting, operating parameters such as speed, power, and frequency are crucial. Each metal type requires specific settings to achieve optimal results. For instance, cutting stainless steel often demands a higher power output, around 150-200 watts, combined with a speed of approximately 0.5–2 meters per minute. Studies indicate that improper settings can lead to issues like dross formation and edge quality degradation.

Frequency plays a vital role in managing the material interaction with the laser beam. Typical fiber lasers operate on a frequency range of 20–100 kHz for cutting metal. However, variations in frequency can produce distinct outcomes. A lower frequency may enhance cutting quality but elongate the cutting time. Conversely, a higher frequency can boost speed but risks compromising edge integrity. Striking the right balance is key yet often overlooked.

Reflecting on these parameters is essential. Operators sometimes overlook the repercussions of gradual adjustments. A small change in speed can result in significantly increased waste or incomplete cuts. The importance of careful monitoring cannot be overstated. It's an area for improvement and requires ongoing learning and adaptation in practices. The interplay of these parameters can make the difference between success and failure in metal laser cutting.

Maintaining laser cutting machines is crucial for their performance and longevity. Regular maintenance can increase machine efficiency by up to 30%. Key tasks include cleaning optical components and checking alignment. Dirty lenses can reduce cutting quality, leading to waste. An annual inspection is advisable.

The cooling system must operate efficiently. Overheating can damage components and lead to significant downtime. A study found that effective cooling extends the lifespan of laser sources. Regularly inspecting coolant levels and replacing filters is essential.

Users often overlook software updates. Outdated software can slow down operations. Keeping the software current ensures compatibility with the machine and enhances performance. A proactive approach to maintenance can save companies thousands in repairs and downtime costs.