Choosing the right laser CNC machine for metal can be challenging. With various options available, it's important to understand your specific needs. A laser CNC machine for metal can significantly enhance your productivity and precision. However, selecting the right model requires careful consideration.

Cost is a major factor. Often, budget constraints can limit your options. This might lead you to compromise on features. Think about the long-term benefits of investing in quality. A good machine can save time and ensure better results.

Size and power also matter. Is the machine suited for your workspace? A compact model may fit but might lack power for heavier tasks. Reflect on what projects you plan to tackle. Ultimately, the right choice can make a huge difference in your metal fabrication journey.

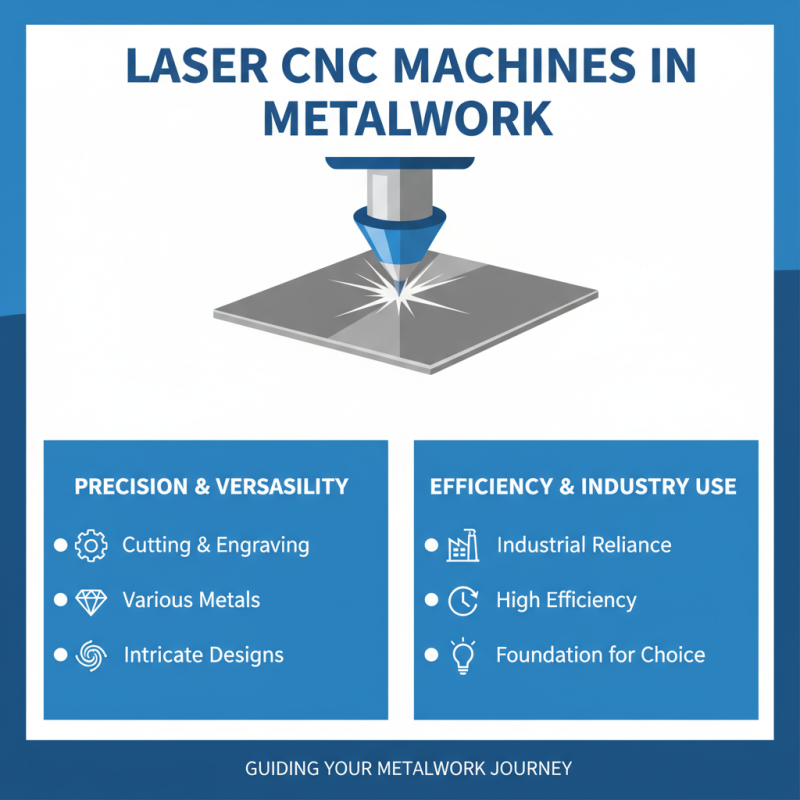

When diving into metalwork, understanding laser CNC machines is crucial. These machines use focused laser beams for precision cutting and engraving. They excel in shaping various metal types with intricate designs. Many industries rely on them for efficiency. Knowing the basics will help guide your choice.

Choosing a laser CNC machine requires careful thought. One key tip is to assess your specific needs. Consider the materials you will use and their thickness. Not all machines handle every metal equally. Another tip involves the machine’s power and speed. A higher wattage usually translates to faster cutting speeds. However, balancing speed with precision is essential.

Don’t forget to look into software compatibility. Some machines have complex software that may require training. Understanding user reviews can also be helpful. Past customers often share useful insights about performance and reliability. Remember, the right fit for your workshop may require experimentation and adjustments.

When selecting a laser CNC machine for metalwork, consider the cutting power. Look for wattage levels that suit your projects. Higher wattage typically means faster cutting and better performance on thicker materials. However, excessive power can burn or distort thinner metals. Balance is key.

Next, evaluate the machine's bed size. A larger bed allows for versatility in handling different workpieces. Smaller machines may limit your options. Think about the projects you plan to undertake. Will you need a machine that accommodates larger sheets? This detail can influence your workflow significantly.

Don't overlook the software compatibility. Many machines require specific software for optimal performance. Ensure the machine you choose can seamlessly integrate with your existing systems. A mismatch can lead to frustration and wasted time. Always prioritize usability and support in your decision-making process. Reflection on past experiences can guide your choices here.

| Feature | Description | Importance |

|---|---|---|

| Laser Type | CO2 laser or fiber laser, each with specific metal cutting capabilities. | High |

| Cutting Thickness | The maximum thickness of metal that can be cut effectively. | Medium |

| Table Size | Dimensions of the work area for accommodating large materials. | High |

| Speed and Power | Rate of cutting and wattage, affecting efficiency. | Very High |

| Software Compatibility | Support for design software to streamline workflow. | Medium |

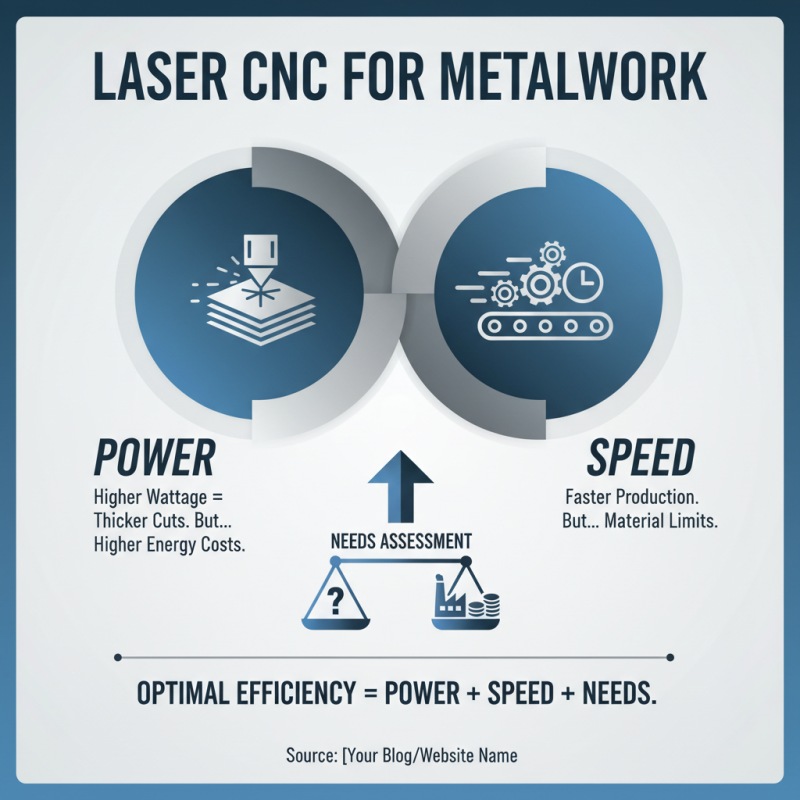

When selecting a laser CNC machine for metalwork, evaluating power and speed is crucial. Power directly influences the machine's ability to cut through various metal thicknesses. A higher wattage means greater cutting capability. However, more power usually comes with higher energy consumption. This can lead to increased operating costs. Therefore, assessing your specific needs is essential.

Speed is another important factor. It determines how quickly the machine can complete a job. Faster machines can increase productivity. But speed should not compromise quality. A balance is necessary. Some metal types require slower cutting for better precision. Evaluating the materials you’ll work with can guide this decision.

In addition, consider that higher power and speed can lead to additional wear on the machine. Maintenance is vital to avoid breakdowns. Understanding the trade-offs is important. It’s not just about choosing the most powerful or fastest option. Think about long-term performance and costs.

When selecting a laser CNC machine for metal, understanding compatibility with various materials and thicknesses is crucial. Different metals behave uniquely under laser cutting. For instance, according to a recent industry report, carbon steel can be cut efficiently up to 20mm thick, while stainless steel poses challenges beyond 15mm due to its thermal properties. Aluminum is even trickier, with a suggested limit of 8mm for optimal results.

Thickness also affects the choice of laser power. A machine with a lower wattage might excel with thin sheets but struggle with thicker materials. Inadequate power can lead to incomplete cuts and poor edge quality. Some users report frustrations with burning and warping when cutting metals like copper and brass at higher thicknesses. This indicates a need for consistent testing and adjustments.

It's essential to review the machine's specifications closely. Not every model is compatible with a full range of metals. Users may mistakenly believe their laser can handle all thicknesses without issues. Proper material testing remains invaluable for achieving the desired outcomes and avoiding costly errors.

When choosing a laser CNC machine for metalwork, budget constraints are a primary concern. These machines can vary widely in price, so it’s crucial to understand the financial implications. Start by assessing your current budget limits. Consider not just the upfront cost but also maintenance and operational expenses. Expect additional costs for accessories and software. Some machines come with hidden fees, so clarify pricing details upfront.

Long-term investment value should also influence your decision. The right machine can generate significant returns if it meets your production needs. Evaluate the machine's reliability and capabilities. Look for units that are easy to upgrade or adapt. An effective machine can last for years, making it a valuable asset. Reflect on how often you will use it and for what types of projects. Consider potential growth in your business and how this machine can facilitate that growth. It’s essential that your choice aligns with future goals, not just immediate needs.