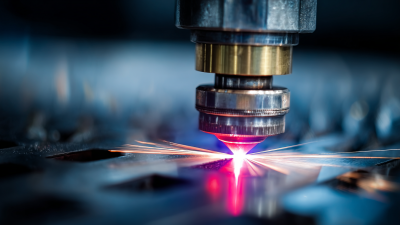

In the ever-evolving landscape of metal fabrication, the integration of advanced CNC laser cutters has marked a significant paradigm shift towards enhanced precision and efficiency. According to a report by MarketsandMarkets, the global CNC laser cutting machine market is expected to reach $4.5 billion by 2025, growing at a CAGR of 5.7% from 2020. This growth underscores the critical role that CNC laser cutters for metal play in optimizing manufacturing processes.

The evolution of CNC laser cutting technology has significantly influenced the metal fabrication industry, driving both precision and efficiency to new heights. The global CNC laser processing systems market was valued at approximately $545 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 10.25% from 2024 to 2030. This rapid growth is fueled by advancements in fiber laser technology, which provides superior cutting quality and speed compared to traditional CO2 lasers.

The evolution of CNC laser cutting technology has significantly influenced the metal fabrication industry, driving both precision and efficiency to new heights. The global CNC laser processing systems market was valued at approximately $545 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 10.25% from 2024 to 2030. This rapid growth is fueled by advancements in fiber laser technology, which provides superior cutting quality and speed compared to traditional CO2 lasers.

In addition to technological advancements, the market for laser cutting equipment is also affected by the increasing demand across various end-use segments, including automotive and jewelry making. For instance, the jewelry manufacturing and precious metals processing equipment market is expected to reach $1.5 billion in 2024, bolstered by a CAGR of 6.3% from 2025 to 2034. As automation and digital design tools gain traction, manufacturers are adopting advanced CNC laser technologies to remain competitive.

Tip: When choosing a CNC laser cutter, consider factors such as the type of laser technology, automation capabilities, and the specific requirements of your projects to maximize productivity and precision.

Tip: Stay updated on industry trends and advancements in CNC technology, as emerging innovations can provide significant advantages in terms of efficiency and cost-effectiveness in metal fabrication.

Advanced CNC laser cutters are transforming the landscape of metal fabrication, offering significant advantages over traditional cutting methods. One of the key benefits is precision. Unlike mechanical cutting techniques, which can introduce variations due to tool wear and operator inconsistencies, CNC laser cutters utilize highly focused beams of light to achieve exact cuts. This technology ensures a high level of accuracy and repeatability, essential for industries where precision is paramount.

Furthermore, the efficiency of advanced CNC laser systems is unmatched. These systems can operate at faster speeds and require minimal setup time, significantly reducing the time from design to production. With the global market for CNC laser processing systems projected to grow at a compound annual growth rate of 10.25% from 2024 to 2030, businesses are increasingly recognizing the value of integrating such technology. The comprehensive supply chain and broad application scope of laser systems further bolster their attractiveness, marking a pivotal shift in how metal fabrication is approached today.

The CNC laser cutting technology is fundamentally transforming the metal fabrication industry by substantially enhancing precision and efficiency. The global CNC machine market is projected to grow from $132.63 billion in 2025 to $229.46 billion by 2032, maintaining a robust compound annual growth rate (CAGR) of 8.1%. This shift towards advanced digital manufacturing methods has resulted in a significant boost in productivity across various sectors, catering to the increasing demand for high-precision and efficiency-driven operations.

Moreover, the CNC laser processing systems market, valued at $545 million in 2022, is anticipated to grow at a CAGR of 10.25% from 2024 to 2030. This growth is indicative of the technology's pivotal role in meeting the industry's stringent requirements. As manufacturers seek greener and more cost-effective solutions, the transition from conventional processes to automated CNC systems is becoming more prevalent. With the global metal manufacturing equipment market expected to rise from $64.64 billion in 2025 to $82.78 billion in 2032, the integration of CNC laser cutters is vital for achieving precision in metal fabrication processes and sustaining competitive advantage in the marketplace.

Modern CNC laser cutting systems are revolutionizing the metal fabrication industry by delivering remarkable efficiency gains that enhance productivity and reduce costs. According to a report by MarketsandMarkets, the global CNC laser cutting machine market is projected to reach $5.08 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 6.5%. This growth is largely driven by the rising demand for precision-based manufacturing in various sectors, including automotive and aerospace.

The advanced technology embedded in modern CNC laser cutters not only improves cutting speeds but also minimizes material waste. For instance, utilizing fiber laser technology can achieve cutting speeds up to 100 inches per minute, which is significantly faster than traditional methods. Additionally, with exceptional precision levels, often reaching tolerances of +/- 0.005 inches, manufacturers can produce intricate designs that were once deemed impossible.

Tip: To maximize the efficiency of your CNC laser cutting operations, maintain a regular schedule for machine maintenance and calibration. This helps in achieving consistently high-quality cuts and prolonging the lifespan of your equipment. Furthermore, consider investing in training for your operators to ensure they are well-versed in the latest techniques and technologies, which can lead to further improvements in your production workflow.

The future of CNC laser technology in metal manufacturing is poised for transformative advancements driven by digitalization, IoT, and AI. According to recent market analyses, the CNC machine market is expected to witness substantial growth, with projections indicating an increase in size to over $18.43 billion between 2024 and 2028. This growth is largely attributed to heightened demand from sectors such as oil and gas, underscoring the essential role of CNC laser systems in enhancing operational efficiency.

Emerging trends also highlight a significant shift towards sustainability in manufacturing. Patent analysis reveals that innovations in electron and laser beam powder bed fusion technologies are paving the way for more sustainable additive manufacturing processes. As the metal cutting tools market is forecasted to reach $113.04 billion by 2030, it is evident that the integration of AI and smart technologies will not only reshape the efficiency and precision of metal fabrication but also ensure that manufacturers meet evolving environmental standards essential for future operations. These advancements indicate a crucial synergy between technology and sustainability that is set to redefine the landscape of metal manufacturing industries.