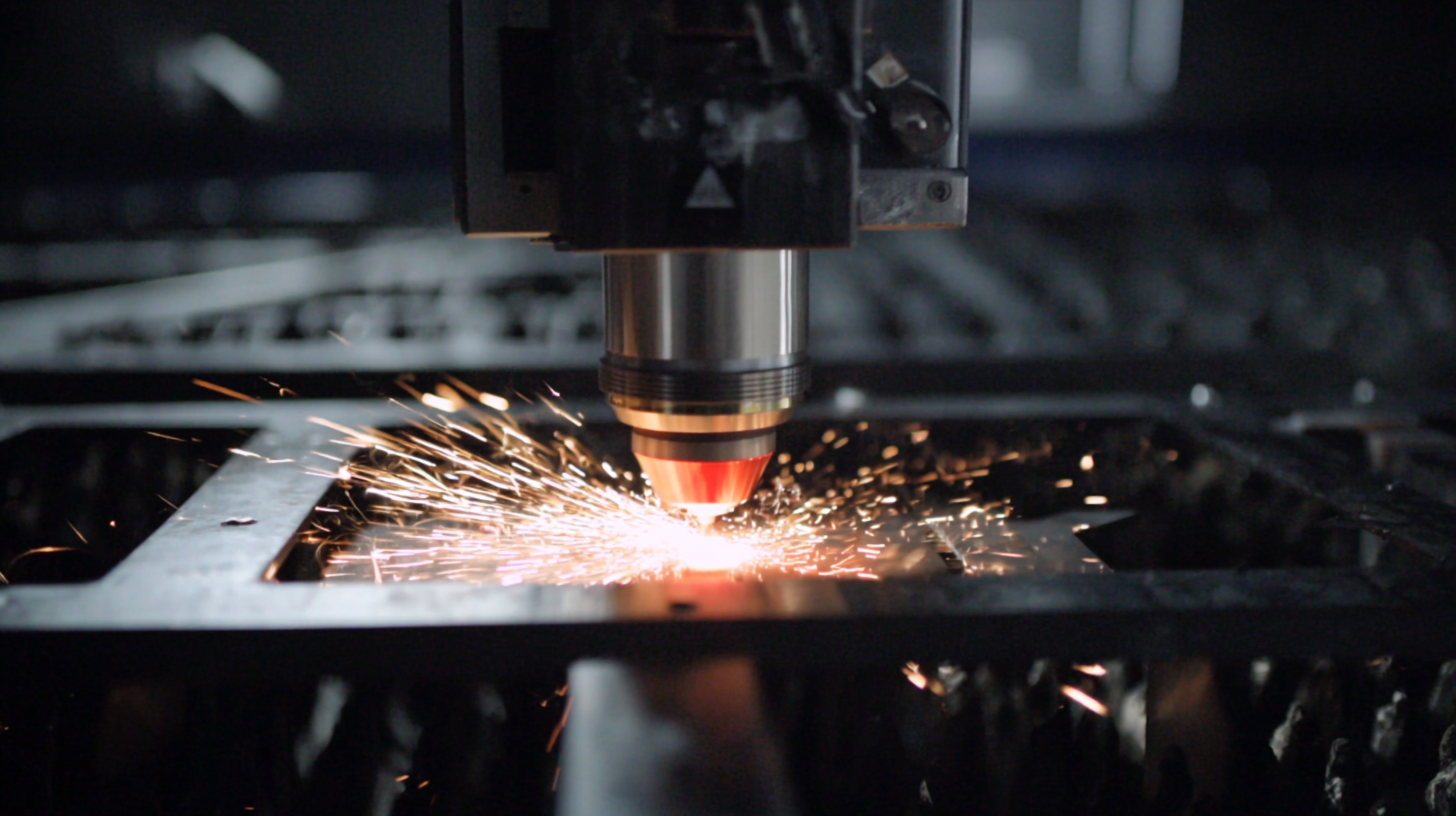

The evolution of manufacturing processes has continuously pushed the boundaries of efficiency and precision, and one of the latest advancements making a significant impact in the industry is

Tube Laser Cutting technology. This innovative technique streamlines metal fabrication, allowing for intricate designs and high-quality finishes that were previously challenging to achieve. As industries demand greater flexibility and speed in production,

Tube Laser Cutting emerges as a game-changer, drastically reducing lead times and material waste while enhancing the overall quality of the finished product.

In this article, we will explore the transformative capabilities of Tube Laser Cutting, shedding light on its operational principles and advantages over traditional fabrication methods. We will delve into how this technology not only simplifies complex cutting tasks but also contributes to a more sustainable manufacturing approach. Whether you are an industry professional seeking to upgrade your processes or a newcomer curious about modern fabrication techniques, understanding the mechanisms and benefits of Tube Laser Cutting will provide valuable insights into the future of metalworking. Join us as we navigate through the intricacies of this revolutionary technology and uncover its potential to reshape the metal fabrication landscape.

Tube laser cutting technology is transforming the landscape of metal fabrication by offering precision and versatility that traditional methods struggle to match. One of the primary advantages of this technology is its ability to produce complex shapes and intricate designs with minimal waste. Unlike conventional cutting methods that may require additional processing to achieve the desired finish, tube laser cutting can create parts with clean edges and high accuracy in a single operation. This not only accelerates the manufacturing process but also significantly reduces material costs.

**Tips:** When implementing tube laser cutting technology, ensure your equipment is regularly calibrated to maintain optimal precision. Additionally, consider investing in dual-tube cutting capabilities, as this can drastically improve your operational efficiency by allowing for simultaneous processing of multiple tube sizes.

Another considerable benefit is the enhanced flexibility it offers. Manufacturers can quickly switch between different projects and easily adjust to varying design specifications, making it ideal for businesses that require quick turnarounds. Furthermore, the ability to integrate with CAD systems allows for seamless transitions from design to production, ultimately enhancing productivity and innovation in metal fabrication.

**Tips:** Incorporate training sessions for your workforce on the latest software and machinery to maximize the benefits of tube laser cutting technology. Staying updated with advancements will ensure you remain competitive in the ever-evolving market.

| Feature | Description | Advantage |

|---|---|---|

| Precision Cutting | Ability to cut complex shapes with high accuracy. | Reduces material waste and improves final product quality. |

| Versatility | Works on a variety of metal types and thicknesses. | Suitable for different applications and industries. |

| Speed | Fast processing times for cutting operations. | Increases production efficiency and reduces lead times. |

| Automation | Integration with automated systems and software. | Enhances workflow and minimizes human error. |

| Reduced Setup Time | Quick changeover between different projects. | Allows for greater flexibility and responsiveness. |

The advent of tube laser cutting technology is transforming the metal fabrication landscape, enabling manufacturers to achieve unprecedented precision and efficiency. Advanced tube laser cutting machines are equipped with features that significantly enhance productivity. According to a recent industry report by MarketsandMarkets, the global laser cutting market is projected to reach $4.5 billion by 2025, highlighting the growing reliance on these advanced systems in fabricating complex structures.

One of the standout features of modern tube laser cutting machines is their ability to handle diverse materials and complex geometries. With high-powered lasers, these machines can cut through materials such as stainless steel, aluminum, and carbon steel with remarkable accuracy. Moreover, they incorporate real-time feedback systems that monitor cutting quality, greatly reducing waste and increasing throughput. A report from IBISWorld indicates that businesses utilizing laser cutting technologies can reduce their operational costs by up to 30% compared to traditional cutting methods, making these machines not only innovative but also economically advantageous for manufacturers.

Additionally, the integration of automation and software advancements allows for seamless operation and quicker changeover times, significantly improving overall workflow. As manufacturers continue to seek innovative solutions to meet increasing demand for customized products, the key features of advanced tube laser cutting machines will play a crucial role in redefining efficiencies within the metal fabrication industry.

Tube laser cutting technology has emerged as a transformative force in metal fabrication, enabling industries to achieve unprecedented levels of precision and efficiency. One notable application is in the automotive sector, where manufacturers utilize tube laser cutting for creating intricate vehicle frameworks and components. This technology allows for complex shapes and designs to be cut with remarkable accuracy, reducing waste and overall production costs. Additionally, the ability to process various materials, including steel and aluminum, makes it a versatile choice for car makers aiming to enhance performance while maintaining structural integrity.

In the construction and architecture industries, tube laser cutting is being harnessed to produce innovative structural elements that challenge conventional design limits. Custom balustrades, handrails, and architectural features can be crafted with intricate patterns that not only enhance aesthetics but also ensure durability. Furthermore, the aerospace sector benefits from this technology by utilizing tube laser cutting for lightweight yet strong components, which are crucial for fuel efficiency and performance in aircraft design. As more industries recognize the benefits of tube laser cutting, its applications continue to expand, driving advancements in design and manufacturing processes across the board.

Tube laser cutting technology is transforming the metal fabrication landscape, offering distinct advantages over traditional methods. In traditional metal fabrication, processes like saw cutting or plasma cutting often result in slower production times and increased material waste. According to a report by MarketsandMarkets, the global laser cutting machine market is expected to reach $5.6 billion by 2025, reflecting a significant shift in industry preference towards laser technology due to its precision and efficiency.

In contrast, tube laser cutting enhances productivity by streamlining the cutting process. This technology utilizes focused laser beams that can cut, engrave, or perforate tubes and pipes with high accuracy, reducing the need for secondary operations. A study published in the Journal of Manufacturing Processes highlights that laser cutting technology can reduce cycle times by up to 75% while decreasing material usage by up to 30% compared to traditional methods. This translates to not only cost savings but also a lesser environmental impact, making tube laser cutting a preferred choice for modern manufacturing needs.

The future of tube laser cutting technology is poised for remarkable advancements, driven by emerging trends that enhance efficiency, quality, and output. As the industry grows, particularly in rapidly developing markets, precision engineering and advanced manufacturing techniques are redefining the standards. The integration of high-power lasers is transforming methods in the tube and pipe sector, allowing for intricate designs and improving the accuracy of cuts, which is critical in producing high-quality products. Innovations presented at major industry events showcase how these technologies are reshaping fabrications and leading to a global competitive edge.