The advent of advanced manufacturing technologies has profoundly transformed the industry landscape, with the Iron Laser Cutting Machine emerging as a pivotal tool in this revolution. Recent studies indicate that the global laser cutting market is projected to reach USD 5.83 billion by 2026, growing at a CAGR of 5.4% from 2021. This growth is largely driven by the demand for precision, efficiency, and versatility in cutting materials such as iron, which is critical in various sectors, including automotive and aerospace. The Iron Laser Cutting Machine not only enhances the speed and accuracy of cutting processes but also significantly reduces material waste, aligning with the industry's shift toward more sustainable practices. As manufacturers increasingly adopt these machines, the impact on productivity and operational costs becomes evident, highlighting the importance of laser technology in modern manufacturing.

The evolution of laser cutting technology in manufacturing has dramatically transformed how industries approach metal fabrication. Initially, traditional cutting methods relied heavily on mechanical processes, which often resulted in significant material wastage and longer lead times.

However, the introduction of laser cutting machines revolutionized this landscape, offering precision and efficiency that were previously unattainable. Today, these advanced systems utilize high-powered lasers to deliver clean cuts with minimal thermal distortion, making them an optimal choice for iron and other metals.

Tips for optimizing your laser cutting process include maintaining your laser cutter regularly to ensure optimal performance and investing in quality software that can effectively manage cutting paths and materials. Additionally, utilizing the right type of gas—such as oxygen for ferrous materials—can enhance cutting speed and quality.

On the manufacturing floor, continuous training for operators on the latest technology and techniques can also lead to improved efficiency and productivity in laser cutting applications.

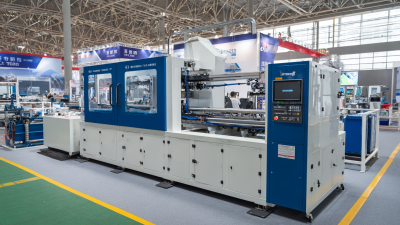

Iron laser cutting machines represent a significant advancement in manufacturing technology, leveraging the principles of optics and heat to achieve precision cuts. These machines operate by directing a highly focused beam of light generated from a laser through a series of lenses. The focused beam is then aimed at the iron surface, where its energy is concentrated to produce extreme heat. This heat melts or vaporizes the metal, allowing for intricate designs and fine tolerances that traditional cutting methods struggle to achieve.

Understanding the operation of iron laser cutting machines requires a grasp of key scientific principles, including the properties of laser light and material interaction. The wavelength of the laser light plays a crucial role in how it interacts with iron, determining both cutting speed and quality. Moreover, the type of laser—commonly CO2 or fiber—also influences performance, with fiber lasers offering advantages in cutting speed and efficiency. As the machine executes movements guided by computer-aided design (CAD) software, it seamlessly combines speed, accuracy, and versatility, thereby transforming the manufacturing landscape and improving overall production efficiency.

The advent of laser cutting technology has significantly transformed the manufacturing landscape, particularly in comparison to traditional methods. Traditional cutting techniques, such as saws and plasma cutting, often involve more extensive mechanical contact with the material. This not only leads to greater wear and tear on tools but also results in more substantial material loss due to the kerf, or the width of the cut.

In contrast, laser cutting machines employ highly focused beams of light, allowing for precise cuts with minimal material wastage. This precision is especially beneficial in industries where material costs are high, such as aerospace and automotive.

In contrast, laser cutting machines employ highly focused beams of light, allowing for precise cuts with minimal material wastage. This precision is especially beneficial in industries where material costs are high, such as aerospace and automotive.

Moreover, the speed of laser cutting far surpasses that of conventional methods. Laser machines can execute complex designs and cut through thick materials in a fraction of the time it would take traditional methods. This rapid processing reduces production timelines, allowing manufacturers to respond more swiftly to market demands. The automation of laser cutting also minimizes human error and enhances safety, as operators are distanced from intense heat and risks associated with traditional cutting methods. Ultimately, the comparative efficiency of laser cutting over traditional techniques underscores its vital role in modern manufacturing practices.

The advent of iron laser cutting machines has dramatically transformed the manufacturing landscape, particularly enhancing speed and precision in production processes.

According to a recent industry report by MarketsandMarkets, the global laser cutting machine market is projected to reach $3.53 billion by 2027, highlighting the increasing reliance on this technology. This surge can be attributed to the ability of laser cutting machines to achieve intricate designs at a speed far exceeding traditional methods, ultimately reducing lead times and improving overall efficiency.

Incorporating laser technology not only propels productivity but also increases accuracy. A study by Research and Markets indicates that laser cutting systems can enhance precision by up to 10 times compared to conventional cutting techniques. Manufacturers adopting this technology experience fewer errors and waste, leading to considerable cost savings. This efficiency is particularly crucial in sectors like automotive and aerospace, where component precision is paramount.

Tips:

To maximize the benefits of laser cutting, manufacturers should invest in operator training to ensure optimal machine utilization. Regular maintenance of laser equipment also plays a crucial role in maintaining consistency and performance, allowing for sustained high-speed production over time. Embracing these practices will further enhance the advantages that iron laser cutting machines offer in modern manufacturing.

The future of laser cutting machines is being shaped by innovative technologies that aim to enhance efficiency and sustainability within the manufacturing sector. As countries like China accelerate their manufacturing upgrades, the demand for high-performance laser equipment is witnessing a significant rise. Innovations in laser technology are not only improving precision and speed in cutting processes but also reducing waste and energy consumption, aligning with global sustainability efforts.

Moreover, trends indicate a strong push towards the localization of manufacturing, which is driving the development of sophisticated laser cutting systems that can manage diverse materials and complex designs. The industry is experiencing a shift towards automated systems that incorporate artificial intelligence and machine learning, further optimizing production processes. As environmental concerns become more pressing, manufacturers are investing in eco-friendly laser cutting technologies, ensuring that growth in this sector aligns with sustainable practices. This synergy between innovation and sustainability is poised to revolutionize manufacturing, paving the way for more efficient and responsible production methodologies in the coming years.