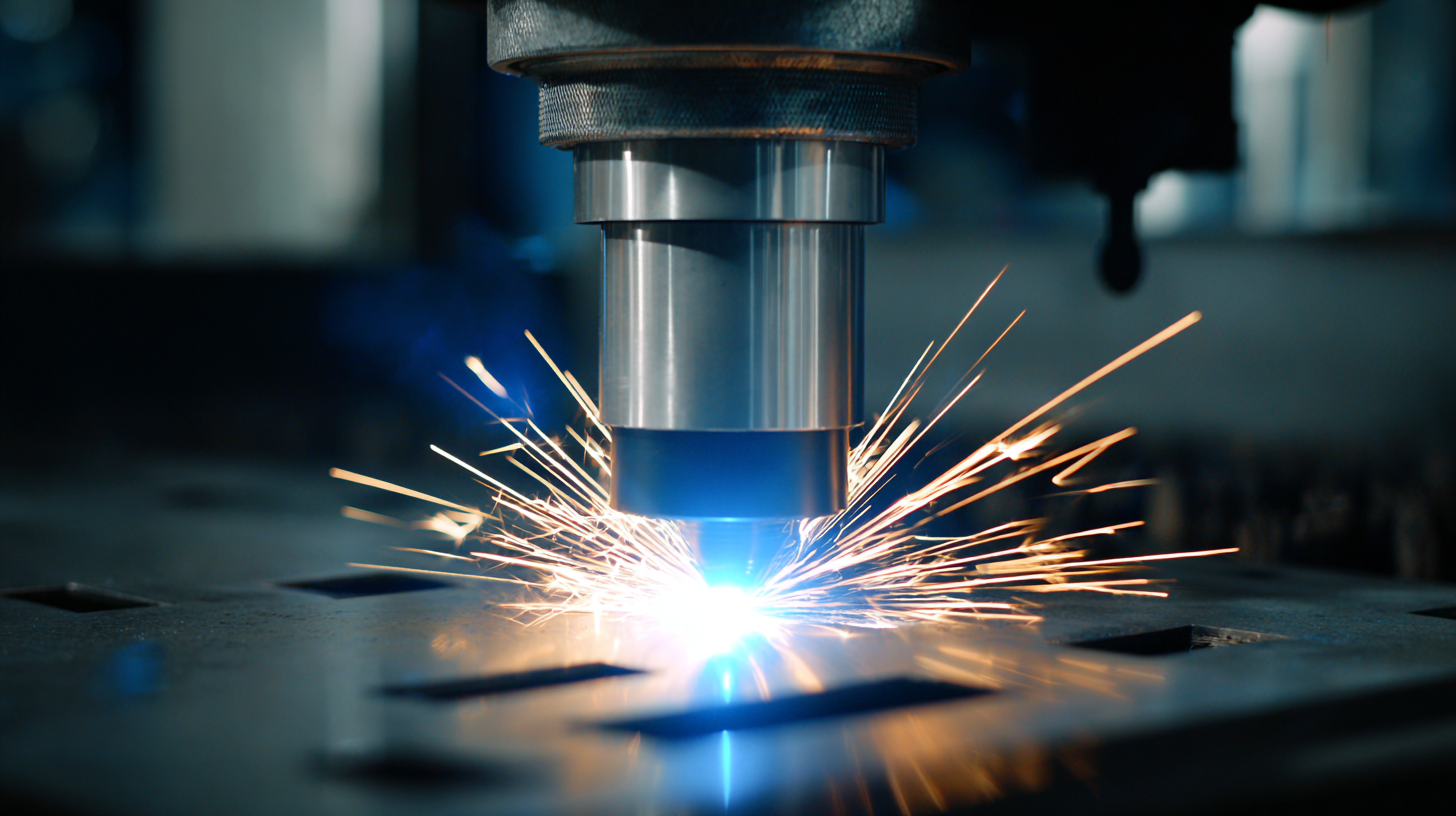

As the manufacturing industry evolves with technological advancements, the demand for precision and efficiency leads to a significant shift towards innovative solutions. One such breakthrough is the Laser Pipe Cutting Machine, which has gained traction due to its ability to deliver high-quality cuts with minimal material wastage. According to a recent report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 4.9 billion by 2025, growing at a CAGR of 5.3%. This growth is fueled by the increasing need for advanced manufacturing techniques across sectors such as automotive, aerospace, and heavy machinery. The introduction of laser cutting technology not only enhances production speed but also reduces operational costs, making it an indispensable tool for modern manufacturers. As we explore the future of this technology, it is essential to recognize its transformative potential in elevating manufacturing standards to unprecedented levels.

Laser pipe cutting technology has been a game-changer in modern manufacturing, offering precision and efficiency that traditional methods struggle to match. This advanced technique utilizes high-powered laser beams to cut through various materials, including metal and plastics, with exceptional accuracy and minimal waste. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $5.8 billion by 2025, highlighting its growing adoption across industries.

One of the key advantages of laser pipe cutting is its versatility. It can handle complex designs and tight tolerances that other cutting methods cannot achieve. This capability not only enhances the overall quality of the products but also reduces the need for extensive post-processing. For manufacturers looking to optimize their operations, integrating laser cutting technology can lead to significant operational cost savings.

**Tip:** When considering laser pipe cutting for your manufacturing needs, assess the material types and thicknesses you frequently work with. Different laser systems cater to specific materials, and choosing the right technology can dramatically improve efficiency.

Additionally, it's essential to stay updated on the latest advancements in laser technology. Implementing the latest innovations can yield higher productivity rates and improved safety standards within the workspace. Investing in training for your technical team can also maximize the potential of this technology, ensuring smooth operation and maintenance.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Precision Cutting | Utilizes focused laser beams to cut various pipe materials accurately. | Increases accuracy, reduces waste. | Automotive, Aerospace, Oil and Gas. |

| Speed | High-speed cutting capabilities that enhance production rates. | Shorter manufacturing times and increased throughput. | Heavy Industry, Construction. |

| Material Versatility | Can cut through a wide range of materials including metals and plastics. | Flexibility in production, suitable for various industries. | Manufacturing, HVAC systems. |

| Automation Integration | Easy integration with automated systems and robotics for enhanced productivity. | Reduced labor costs and improved safety. | Smart Manufacturing, Robotics. |

| Customization | Can easily adjust designs for custom projects without extensive retooling. | Enables unique designs and one-off production easier. | Furniture, Art, Architectural elements. |

Laser cutting technology has significantly shifted the landscape of pipe fabrication, offering several key advantages over traditional cutting methods. One of the primary benefits is precision. Laser cutting delivers highly accurate cuts with minimal tolerances, ensuring that pipes fit together perfectly in assemblies. This level of precision is difficult to achieve with conventional methods, which often result in inconsistent edges and require additional finishing processes. The elimination of these extra steps not only accelerates production but also reduces waste, making laser cutting a more efficient choice for manufacturers.

Another crucial advantage lies in the versatility of laser cutting. It can easily handle a variety of materials, including metals, plastics, and composites, making it ideal for different industries. Traditional cutting methods often require specialized tools and setups for different materials, whereas laser systems can adapt quickly to various tasks with minimal downtime. Additionally, the ability to perform intricate designs and complex geometries with ease opens up new possibilities in product design, enabling manufacturers to innovate without the constraints imposed by older techniques. This flexibility combined with efficiency is driving a shift toward laser technology in pipe fabrication.

Laser pipe cutting technology is transforming operations across various industries due to its versatility and precision. Key sectors such as automotive manufacturing, aerospace, and construction machinery are adopting advanced laser cutting systems to enhance productivity and reduce waste. The innovative applications of fiber and carbon dioxide laser cutters enable manufacturers to achieve intricate designs and impeccable edges, which are essential for modern engineering standards.

Laser pipe cutting technology is transforming operations across various industries due to its versatility and precision. Key sectors such as automotive manufacturing, aerospace, and construction machinery are adopting advanced laser cutting systems to enhance productivity and reduce waste. The innovative applications of fiber and carbon dioxide laser cutters enable manufacturers to achieve intricate designs and impeccable edges, which are essential for modern engineering standards.

As the market for CNC laser processing systems is projected to grow significantly, reaching an estimated value of $5.45 billion by 2022, the trend indicates a compound annual growth rate of 10.25% from 2024 to 2030. This growth is driven by the increased demand for more efficient and capable cutting solutions that can handle complex geometries and a variety of materials. Furthermore, the emergence of servo-driven laser cutting machines is catering to specific industry needs, ensuring that manufacturers can maintain a competitive edge in an increasingly demanding marketplace.

The integration of automation and artificial intelligence (AI) in laser cutting systems is revolutionizing the manufacturing landscape. This technological advancement not only enhances efficiency but also significantly improves precision in operations. As laser cutting technology evolves, manufacturers are increasingly adopting AI to optimize processes, reduce waste, and ensure consistent quality. The ability of AI systems to analyze data in real-time allows for adaptive cutting strategies, leading to more streamlined production workflows.

In 2024, the laser equipment market in China is projected to reach a remarkable revenue of 91 billion RMB, showcasing a substantial growth compared to previous years. The cutting equipment segment alone is anticipated to achieve a market scale of 36.85 billion RMB. This surge highlights the increasing reliance on innovative laser technologies across various industries. As businesses seek to maintain a competitive edge, the convergence of automation and AI in laser pipe cutting technology will play a pivotal role in shaping the future of manufacturing.

Implementing laser pipe cutting technology can significantly enhance manufacturing efficiency and precision, but success hinges on a few essential strategies. According to a report by Markets and Markets, the laser cutting market is expected to reach $5.33 billion by 2025, growing at a CAGR of 6.7% from 2020. This rapid growth underscores the increasing demand for precise and versatile cutting solutions in various industries, including aerospace, automotive, and HVAC. To stay competitive, manufacturers must focus on training staff to operate advanced laser systems and maintain equipment regularly to avoid downtime.

Implementing laser pipe cutting technology can significantly enhance manufacturing efficiency and precision, but success hinges on a few essential strategies. According to a report by Markets and Markets, the laser cutting market is expected to reach $5.33 billion by 2025, growing at a CAGR of 6.7% from 2020. This rapid growth underscores the increasing demand for precise and versatile cutting solutions in various industries, including aerospace, automotive, and HVAC. To stay competitive, manufacturers must focus on training staff to operate advanced laser systems and maintain equipment regularly to avoid downtime.

Another critical factor is the integration of automation within laser cutting operations. A study by Grand View Research indicates that automated laser cutting systems can increase productivity by up to 20% compared to manual cutting processes. By utilizing advanced software for design and cutting path optimization, manufacturers can minimize waste and improve material yield. Additionally, investing in real-time monitoring technologies can provide valuable data insights, allowing for proactive adjustments and greater overall efficiency in production workflows.