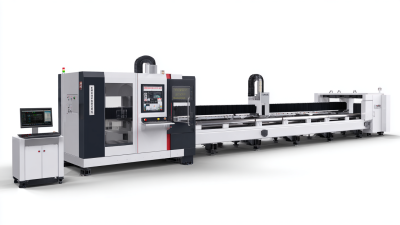

In the rapidly evolving landscape of metal fabrication, the efficiency of a Steel Laser Cutter is paramount for enhancing productivity and reducing operational costs. According to a report by the International Laser Display Association, the global market for laser cutting machines is projected to reach USD 5.14 billion by 2025, underscoring the increasing reliance on advanced laser technology in manufacturing. As companies strive to leverage this powerful tool, optimizing the performance of Steel Laser Cutters becomes essential to stay competitive in a demanding market. By implementing strategic tips geared towards maximizing efficiency, businesses can not only streamline their processes but also significantly enhance output quality and reduce waste, ultimately leading to improved profitability. In this blog, we will explore five essential strategies that industry professionals can adopt to optimize their Steel Laser Cutter operations.

When optimizing your steel laser cutter's efficiency,

understanding material thickness is crucial.

According to a report by the Fabricators & Manufacturers Association, different thicknesses of steel

require specific laser settings to achieve optimum results. For instance, a fiber laser with a power output

of 3000 watts is ideal for cutting materials up to

12 mm thick, while thicker materials, such as

25 mm steel, may necessitate a higher power output

or a controlled cutting speed to prevent thermal distortion.

When optimizing your steel laser cutter's efficiency,

understanding material thickness is crucial.

According to a report by the Fabricators & Manufacturers Association, different thicknesses of steel

require specific laser settings to achieve optimum results. For instance, a fiber laser with a power output

of 3000 watts is ideal for cutting materials up to

12 mm thick, while thicker materials, such as

25 mm steel, may necessitate a higher power output

or a controlled cutting speed to prevent thermal distortion.

One essential tip is to fine-tune your laser’s focal point

based on material thickness. A well-adjusted focal point can enhance the cutting quality and speed, reducing the chances of

dross formation. Additionally, consider experimenting with different gas assist types,

such as nitrogen or oxygen, depending on the thickness being cut. Nitrogen typically provides a cleaner edge

for stainless steel, while oxygen can increase cutting speed for mild steel.

Moreover, staying informed about advancements in laser technologies can significantly impact efficiency. Regularly reviewing

industry publications can help you adopt new techniques, such as utilizing advanced motion systems that can increase throughput.

Applying these strategies in conjunction can lead to significant productivity gains, helping you maximize output in your

steel processing operations.

Regular maintenance is crucial to ensuring your steel laser cutter operates at peak efficiency. According to a recent report from the Laser Institute of America, regular upkeep can improve laser cutter performance by up to 30%. This not only prolongs the lifespan of your equipment but also significantly enhances production output. Key steps include regularly checking and replacing filters, ensuring lenses are clean, and lubricating moving parts to avoid unnecessary wear and tear.

Incorporating routine inspections can help identify potential issues before they escalate. A well-maintained machine minimizes downtime, which is essential in today's fast-paced manufacturing environment. Research indicates that companies that prioritize equipment maintenance save an average of 15% on operational costs annually. To optimize your steel laser cutter, schedule monthly maintenance checks to inspect alignment, calibration, and software updates.

Moreover, keeping a maintenance log can be incredibly beneficial. Documenting every service and part replacement provides insight into your equipment's performance trends and can inform future maintenance strategies. Leveraging technology, such as predictive maintenance software, can enhance your ability to anticipate issues, ensuring that your operations remain smooth and efficient. Prioritizing these maintenance tasks not only boosts your productivity but also reduces the risk of costly repairs down the line.

| Maintenance Task | Frequency | Description | Impact on Efficiency |

|---|---|---|---|

| Lens Cleaning | Daily | Remove dust and debris from the lens to ensure optimal cutting quality. | Prevents failed cuts and improves beam focus. |

| Mirror Check | Weekly | Inspect mirrors for cleanliness and alignment. | Maintains beam integrity and cutting precision. |

| Software Updates | Monthly | Ensure machine software is up-to-date for optimal performance. | Enhances operation features and stability. |

| Lubrication | Monthly | Apply lubricant to moving parts to minimize wear. | Reduces mechanical failure and prolongs lifespan. |

| Calibration | Quarterly | Ensure the machine is correctly calibrated for accurate cuts. | Improves cutting accuracy and reduces material waste. |

When it comes to enhancing the efficiency of a steel laser cutter, selecting the right lens is critical for achieving optimal cutting precision and speed. According to a report by the Laser Institute of America, the lens quality can influence the beam profile and focus, impacting the cut edge's quality and overall machining speed. The right lens can improve focus, leading to sharper cuts and a smoother finish, while the wrong choice may result in subpar performance and increased operational costs.

Different lens focal lengths cater to specific material thicknesses and cutting applications. For instance, a shorter focal length lens can create a more concentrated beam, making it suitable for thin materials, while a longer focal length lens provides a wider focal area, ideal for thicker steel. The National Institute of Standards and Technology suggests that optimizing the lens choice according to these parameters can enhance efficiency by up to 30%, significantly reducing the time spent on setup and adjustments. This precision not only accelerates production processes but also minimizes the risk of waste associated with cutting errors. As such, investing in the correct lens based on material specifications is an essential step in maximizing your steel laser cutter's performance.

In the world of metal fabrication, optimizing the workflow of your steel laser cutter can significantly impact productivity and output quality. A streamlined cutting process begins with proper planning and preparation. Take the time to organize your materials and ensure that all necessary tools and components are easily accessible. Implementing a systematic approach to loading and unloading materials can drastically reduce downtime and keep your cutter running efficiently.

Furthermore, incorporating advanced software for workflow management can help in scheduling jobs, tracking performance, and identifying bottlenecks in the cutting process. Utilizing nesting software can maximize material usage by minimizing waste, while also contributing to faster cutting times. Regular maintenance of the laser cutter is essential; ensuring that the equipment is in peak condition prevents unexpected failures and sluggish performance, allowing for a seamless operation.

By focusing on these key areas, you can create an environment where efficiency thrives. Ultimately leading to higher output and better quality finishes in your laser cutting projects.

In the world of metal fabrication, software solutions play a crucial role in enhancing the performance of steel laser cutters. By integrating advanced software programs, users can optimize cutting paths, minimize material waste, and automate process adjustments in real time. These tools allow operators to input specific parameters and achieve precise cuts, significantly reducing the time spent on manual adjustments and enhancing overall production efficiency.

Modern software solutions also offer capabilities such as predictive maintenance, which ensures that the laser cutter operates at peak performance. By analyzing machine data, these applications can forecast potential issues before they occur, allowing for timely interventions and minimizing downtime. Additionally, advanced features like remote diagnostics and real-time monitoring empower shop managers to oversee operations from anywhere, ensuring that any inefficiencies can be quickly addressed. With technology continuously evolving, leveraging these software solutions is essential for anyone looking to maximize their steel laser cutter’s productivity and longevity.