In today's competitive landscape, businesses are constantly seeking innovative solutions to enhance operational efficiency and reduce production costs. One such technology that has emerged as a game-changer is Metal Laser Cutting. This advanced method not only offers precision and speed but also minimizes material waste, allowing companies to optimize their manufacturing processes. By leveraging Metal Laser Cutting, businesses can achieve intricate designs and complex geometries that were previously challenging with traditional cutting methods. In this article, we will delve into various insights and techniques to harness the full potential of Metal Laser Cutting, exploring how it can streamline workflows, improve product quality, and ultimately drive profitability. Whether you are a seasoned manufacturer or a newcomer to the industry, understanding these strategies will empower you to elevate your business efficiency through the cutting-edge capabilities of Metal Laser Cutting.

Metal laser cutting technology has become a pivotal component in enhancing business efficiency across various manufacturing sectors. As the global fiber laser cutter market is projected to grow from USD 2.16 billion in 2025 to USD 3.35 billion by 2034, appreciating a compound annual growth rate (CAGR) of 5%, it is evident that industries are recognizing the benefits of adopting advanced laser cutting techniques. This growth is not solely about investment; it underscores the importance of understanding the foundational elements that contribute to laser cutting quality, which significantly impacts production outcomes.

Metal laser cutting technology has become a pivotal component in enhancing business efficiency across various manufacturing sectors. As the global fiber laser cutter market is projected to grow from USD 2.16 billion in 2025 to USD 3.35 billion by 2034, appreciating a compound annual growth rate (CAGR) of 5%, it is evident that industries are recognizing the benefits of adopting advanced laser cutting techniques. This growth is not solely about investment; it underscores the importance of understanding the foundational elements that contribute to laser cutting quality, which significantly impacts production outcomes.

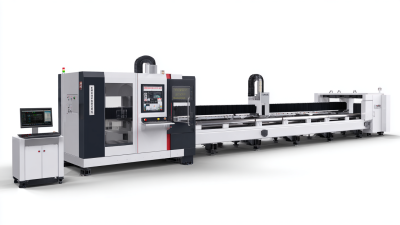

At the heart of optimized metal cutting lies operator skill and proficiency in laser cutting principles. Even in automated environments, the understanding of fundamental concepts is crucial for achieving desired results. Workers must be well-versed in techniques that balance the cutting speed with the load-bearing strength of the machine beds to ensure precision and efficiency in fabrication. Moreover, the integration of additive manufacturing in conjunction with traditional CNC machining processes can provide a progressive pathway for companies to enhance their manufacturing capabilities, leveraging existing competencies to innovate in an increasingly competitive market.

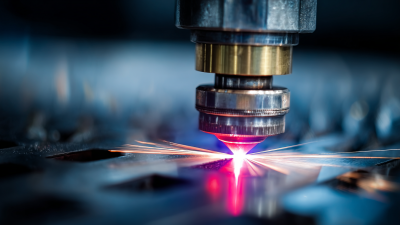

Metal laser cutting technology offers significant benefits for businesses looking to enhance their operational efficiency. One of the key advantages is precision; laser cutting provides highly accurate cuts, reducing material waste and minimizing the need for rework. This precision allows manufacturers to achieve intricate designs and complex geometries that are often difficult or impossible to accomplish with traditional cutting methods. As a result, companies can optimize their production processes and improve overall product quality, leading to increased customer satisfaction and loyalty.

Another important benefit of metal laser cutting is its speed and flexibility. Laser cutting machines can rapidly process a range of materials, enabling manufacturers to increase their output while maintaining high levels of quality. This flexibility allows businesses to quickly adapt to market changes and customer demands, reducing lead times and improving responsiveness. Moreover, advancements in laser technology, coupled with projected growth in the industrial laser market, indicate that businesses embracing this cutting-edge technology are well-positioned to thrive in an increasingly competitive landscape. By investing in efficient laser cutting solutions, companies can not only enhance their productivity but also drive long-term success.

Metal laser cutting has emerged as a cornerstone technology in the manufacturing sector, particularly in enhancing precision and quality. According to a report by IBISWorld, the metal fabrication industry has seen a significant transformation, with laser cutting accounting for a substantial portion of the market, projected to grow at an annual rate of over 5% through 2025. To optimize this process, businesses can implement several techniques that not only enhance accuracy but also improve operational efficiency.

One critical technique is the use of advanced nesting software, which maximizes material utilization by intelligently arranging cut patterns. This method can reduce waste by up to 15%, translating into significant cost savings. Additionally, the adoption of high-quality laser heads and lenses allows for finer edge quality and reduced post-processing, enabling manufacturers to achieve tolerances as tight as ±0.01 mm. Furthermore, regular maintenance and calibration of laser systems ensure optimal performance, prolonging equipment life and avoiding unexpected downtime, contributing to an overall increase in production efficiency. By leveraging these insights and embracing modern technologies, businesses can elevate their metal cutting operations while maintaining the highest standards of quality.

In today's competitive landscape, optimizing business efficiency through metal laser cutting can significantly enhance workflow processes. By integrating advanced laser cutting technologies, companies can streamline operations, reduce production times, and minimize material waste. According to recent studies on lean manufacturing concepts, businesses adopting these methodologies have seen efficiency improvements of up to 30%, alongside substantial waste reduction. This synergy of laser cutting and lean principles not only accelerates production cycles but also allows resources to be allocated more effectively, resulting in overall operational cost savings.

Moreover, the incorporation of automated laser cutting solutions can further drive efficiency. Recent advancements in automation technologies have revolutionized traditional manufacturing practices, allowing for precision and consistency that human operators cannot always achieve. For instance, the latest innovations in laser automation can reduce setup times by as much as 50%, facilitating the swift transition between different production runs. As industries increasingly embrace digital transformation, leveraging laser cutting techniques in conjunction with automation will undoubtedly empower businesses to enhance their operational frameworks and adapt swiftly to market demands.

To maintain optimal efficiency in metal laser cutting operations, it’s crucial to focus on the regular upkeep and upgrading of your laser cutting equipment. Routine maintenance checks can help identify wear and tear on critical components such as lenses, mirrors, and the cutting head. By ensuring these parts are clean and functioning effectively, businesses can significantly reduce downtime and ensure consistent cutting quality. Implementing a structured maintenance schedule allows companies to preemptively address issues, thereby extending the equipment's lifespan and enhancing overall productivity.

Furthermore, upgrading laser cutting technology and software is essential for keeping pace with industry advancements. Newer models often feature improved precision, speed, and energy efficiency, which can result in lower operational costs and higher output. Incorporating advanced software can also streamline processes, enabling better integration with design systems and automating various tasks. Regularly investing in both hardware and software upgrades not only boosts efficiency but also keeps your business competitive in a rapidly evolving market.