In the ever-evolving realm of manufacturing and fabrication, the significance of precision and efficiency cannot be overstated. Laser pipe cutting machines have emerged as vital tools, empowering industries to achieve superior cutting quality while minimizing waste and production time. As noted by industry expert Dr. Alex Thompson, a leading voice in advanced cutting technologies, "The introduction of laser pipe cutting machines has revolutionized the way we approach metal fabrication, providing unmatched accuracy and flexibility in designs."

This technology not only enhances productivity but also opens new avenues for innovation across various sectors. As we delve into the top 10 laser pipe cutting machines available today, we will explore their standout features, pricing considerations, and expert recommendations. Each machine brings its own unique advantages that cater to different needs, from small workshops to large-scale industrial operations.

Join us as we navigate this crucial aspect of manufacturing, highlighting the machines that stand out in the market and the innovative technologies steering the future of the industry. Whether you are a seasoned professional or just beginning to explore the potential of laser pipe cutting machines, this guide aims to serve as an invaluable resource in making informed decisions.

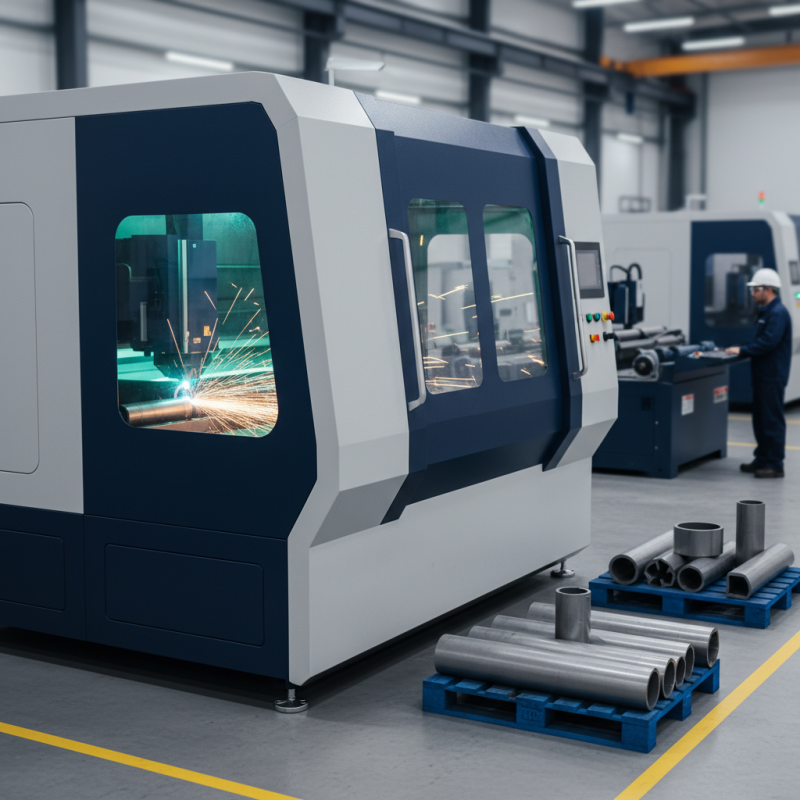

Laser pipe cutting machines have emerged as essential tools in various industries, significantly enhancing productivity and precision in metal fabrication. These advanced machines utilize high-powered lasers to cut through a range of materials with exceptional accuracy, making them indispensable for manufacturing sectors like automotive, aerospace, and construction. The precision of laser cutting minimizes material waste and allows for complex designs that traditional cutting methods cannot achieve.

The importance of these machines extends beyond just efficiency; they also offer versatility and reduce operational costs. Laser pipe cutting machines can adapt to different pipe sizes and materials, making them suitable for diverse applications. Additionally, the automation capabilities enable manufacturers to streamline their processes, decrease labor costs, and increase throughput. As industries continue to embrace advanced technologies, the role of laser pipe cutting machines will undoubtedly grow, positioning them as pivotal assets in modern fabrication environments.

| Model | Cutting Diameter (mm) | Laser Power (kW) | Max Cutting Speed (m/min) | Price (USD) |

|---|---|---|---|---|

| Model A | 60 | 2 | 20 | 10,000 |

| Model B | 80 | 3 | 18 | 12,500 |

| Model C | 100 | 4 | 25 | 15,000 |

| Model D | 120 | 5 | 30 | 18,000 |

| Model E | 50 | 2.5 | 22 | 11,000 |

| Model F | 70 | 3.5 | 21 | 13,000 |

| Model G | 110 | 4.5 | 28 | 17,000 |

| Model H | 90 | 6 | 24 | 20,000 |

| Model I | 130 | 7 | 26 | 22,000 |

| Model J | 140 | 8 | 35 | 25,000 |

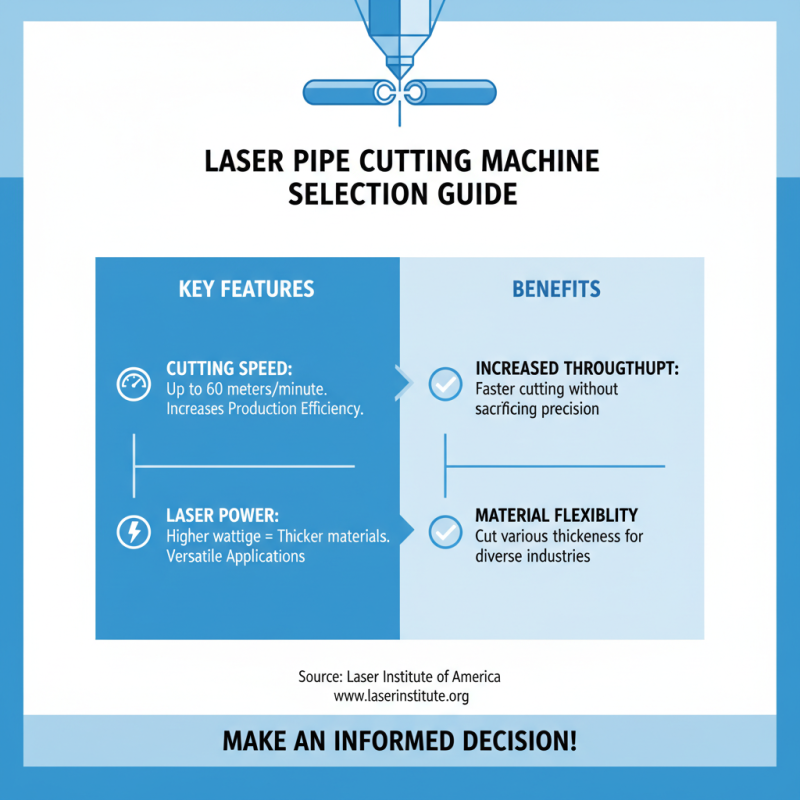

When selecting a laser pipe cutting machine, understanding the key features is essential for making an informed decision. One of the primary considerations is the cutting speed, which significantly affects production efficiency. According to the Laser Institute of America, advanced laser cutting systems can achieve speeds of up to 60 meters per minute, increasing throughput without compromising precision. Additionally, the power of the laser source is critical; machines that offer higher wattage can cut thicker materials more efficiently, catering to various industrial applications.

Another vital feature is the automation capabilities of the machine. Modern laser pipe cutting machines are increasingly equipped with automated handling systems that streamline workflow and minimize manual intervention. A report by MarketsandMarkets indicates that automation in manufacturing can lead to efficiency improvements of up to 30% in operational tasks. Furthermore, consider the cutting capacity in terms of pipe diameter and material types; machines capable of handling a wide range of substrates, such as stainless steel, aluminum, and carbon steel, provide versatility for diverse production needs. These elements contribute significantly to a machine's overall performance and suitability for specific manufacturing environments.

When considering the acquisition of laser pipe cutting machines, understanding the price range is essential for making an informed decision. These machines vary significantly in cost, typically falling into three primary categories: entry-level, mid-range, and high-end. Entry-level machines are often priced between $10,000 to $30,000, offering basic features suitable for smaller operations or occasional use. They may have limited cutting capabilities and lower power, making them ideal for simpler tasks in smaller workshops.

Mid-range machines, usually priced between $30,000 to $70,000, present a balance of performance and advanced features. They often come with enhanced cutting speeds, better precision, and more versatility in material processing. These machines cater to medium-sized businesses that require more robust solutions for a wider range of applications. On the other hand, high-end laser pipe cutting machines can exceed $70,000, offering cutting-edge technology, automation features, and the ability to handle large volumes of complex cuts. These machines are designed for large manufacturing operations where efficiency, speed, and precision are paramount. By understanding these price ranges, buyers can better assess their needs and budget for the right equipment.

When exploring the realm of laser pipe cutting machines, understanding their features and specifications is crucial for making an informed decision. In this comparative review, we delve into the top ten models available in the market, each offering unique capabilities tailored to different industrial requirements. From precision cutting to automation features, these machines vary significantly in terms of speed, power, and operational efficiency, making it essential for manufacturers to select the one that aligns with their production needs.

Price is another vital consideration when evaluating laser pipe cutting machines. The cost of these systems can range considerably, influenced by their technology and functionality. Our review highlights not only the price points of each machine but also provides insights into the value offered at each level, helping potential buyers understand which investment can yield the best returns in terms of productivity and longevity. By comparing these models, buyers can make educated choices that enhance their manufacturing processes while staying within budget.

When it comes to laser pipe cutting machines, customer reviews play a crucial role in guiding prospective buyers toward the best options available. Users often highlight the precision and efficiency these machines offer, allowing for intricate designs and clean cuts with minimal waste. Many reviews emphasize the importance of selecting models with advanced features such as adjustable cutting speeds and built-in software for better control over the cutting process. Feedback also indicates that reliable customer support and ease of operation significantly enhance the overall experience, ensuring that businesses can keep production running smoothly.

Additionally, real-world recommendations provide insights into the long-term performance of these machines. Customers frequently mention the durability and maintenance requirements of their chosen models, which can vary significantly. Reviews often compare initial purchase prices with operational costs over time, emphasizing that investing in a higher-quality machine can lead to better savings and output in the long run. By considering customer experiences and recommendations, potential buyers can make more informed choices, leading to greater satisfaction and productivity in their cutting operations.