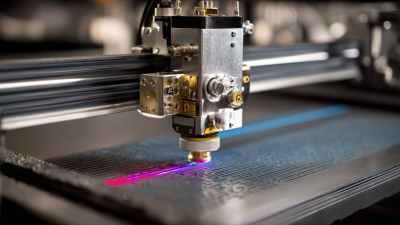

A Laser CNC Machine combines advanced technology with precision engineering. This system uses a focused laser beam to cut, engrave, or etch materials. The versatility of a laser CNC machine makes it essential in various industries, from manufacturing to art.

The process begins with a computer-aided design (CAD) file that outlines the desired pattern. The machine interprets this file and translates it into commands that guide the laser. The laser's intensity and speed can be adjusted, providing different results based on the material. While many operators find the process straightforward, mistakes can occur.

Understanding the limitations of a laser CNC machine is vital. One could underestimate the impact of material thickness or density on the cutting process. Additionally, operator skill can vary, impacting quality. A precise setup is necessary, but even then, outcomes may not always meet expectations. This complexity makes continued learning essential for anyone working with laser technology.

A laser CNC machine is a computer-controlled device that uses laser technology for cutting or engraving. This technology offers precision and speed, making it a popular choice in manufacturing. The laser beam can cut through various materials like wood, metal, and plastic. According to industry reports, the global laser cutting market is projected to reach USD 8.6 billion by 2026, reflecting a strong demand for these machines.

Key characteristics of a laser CNC machine include high accuracy and versatility. They can create intricate designs, making them ideal for industries like automotive and aerospace. Easily programmable, these machines can execute complex tasks with minimal human intervention. However, challenges remain. Some operators struggle with maintenance and calibration, which can affect output quality. Inadequate training can lead to accidents or wastage of materials, highlighting the need for thorough instructional programs.

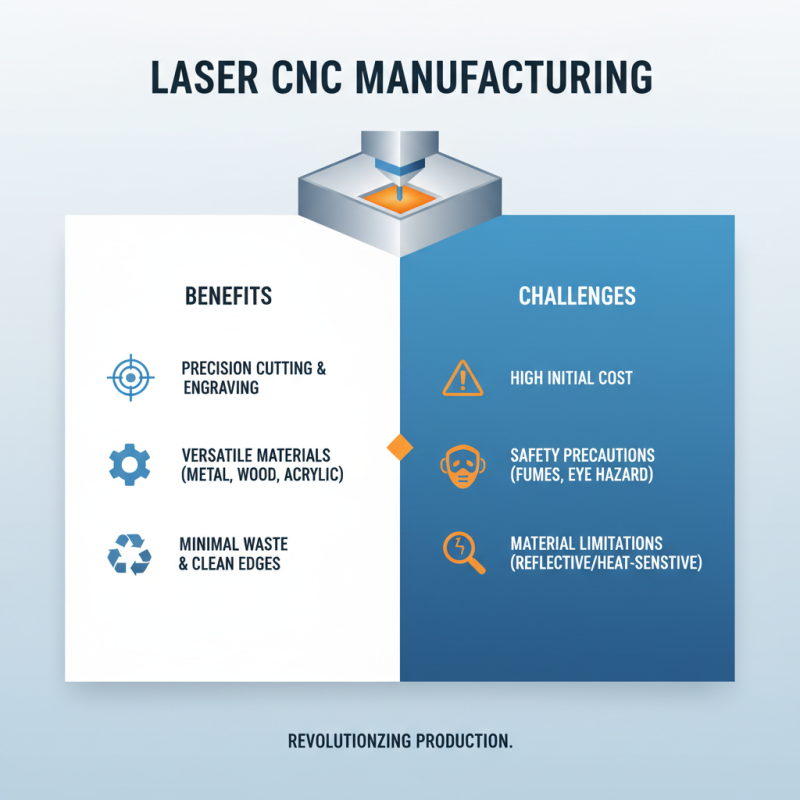

High initial costs can deter some businesses from investing. However, the long-term benefits often justify the expense. Laser CNC machines require proper ventilation due to fumes produced during operation. This aspect often gets overlooked, leading to potential health hazards. Businesses need to balance the extraordinary capabilities of laser CNC machines with these operational realities.

| Dimension | Description |

|---|---|

| Definition | A Laser CNC machine is a type of computer numerical control equipment that utilizes laser technology for cutting, engraving, and marking materials. |

| Key Components | Laser source, CNC controller, motion system, processing head. |

| Materials Used | Metals, wood, plastics, leather, glass, fabric. |

| Applications | Manufacturing, signage, art, prototyping, jewelry making. |

| Advantages | High precision, speed, versatility, minimal material waste. |

| Limitations | Limited thickness for cutting, potential high operational costs. |

| Working Principle | Laser light is focused through lenses to create a narrow, intense beam that melts, burns, or vaporizes material. |

| Control Software | Uses software to create and transfer designs to the CNC controller for processing. |

A Laser CNC machine uses focused light to cut and engrave materials. The process begins with the programming of a design. Software translates these designs into commands for the CNC machine. This is where the magic starts. The laser beam, directed by mirrors, follows the programmed paths.

As the beam moves, it heats the material. The high temperature causes it to either melt or vaporize, depending on the settings. It is crucial to adjust power settings precisely. Too much power can burn the material, while too little may not cut through. Users often spend time fine-tuning these settings.

Cooling systems often accompany laser CNC machines. They help maintain the optimal temperature during operations. This avoids excessive wear and tear. However, this can be a challenge, as users must monitor the machine closely. Parts may need replacement sooner than expected. Understanding the equipment's limitations helps achieve better results. Each project offers lessons in precision and patience.

Laser CNC machines utilize various laser technologies, each with unique capabilities. The most common types include CO2, fiber, and Nd:YAG lasers. CO2 lasers are versatile and work well with non-metal materials like wood and acrylic. They produce an intense beam that can cut and engrave with precision.

Fiber lasers, on the other hand, are known for their efficiency. They excel at cutting metals with high speed and accuracy. Their compact design requires less maintenance than other lasers. Nd:YAG lasers are often used for welding and marking. They can handle thicker materials, but their operational costs can be higher.

Each technology has its pros and cons. For instance, while fiber lasers are incredibly efficient, they might struggle with some thicker non-metal materials. CO2 lasers are great for engravings, but their speed is slower compared to fiber lasers. It is important to choose the appropriate technology based on the materials involved and the desired outcome. Being aware of these differences can lead to better decision-making in a CNC routing project.

This chart illustrates the percentage use of various laser technologies in CNC machines, showcasing the CO2 laser as the most commonly used technology, followed by fiber lasers, Nd:YAG lasers, diode lasers, and solid-state lasers.

Laser CNC machines are revolutionizing various industries. Their precision allows for intricate designs and detailed cuts. In manufacturing, these machines increase efficiency. They help create parts with tight tolerances. This technology is prevalent in aerospace and automotive sectors. These industries rely on accuracy for safety.

In the realm of fashion and interior design, laser CNC machines offer unique possibilities. Designers cut intricate patterns into fabrics and wood. This method enhances creativity. However, there are challenges. Sometimes, materials can burn or warp. The settings must be adjusted carefully.

Tips: Always test on scrap material. Find the right speed and power settings for each material. Regular maintenance is crucial for optimal performance. Ensure your workspace is clean to avoid accidents. Staying organized can help in meeting deadlines.

Laser CNC machines have revolutionized the manufacturing landscape. They offer precision cutting, engraving, and etching on various materials. This technology utilizes a focused laser beam to vaporize or melt the material, creating intricate designs. The result is a clean edge and minimal material waste. However, it’s not without its challenges.

One key advantage of laser CNC machines is their flexibility. They can work with metals, plastics, and wood, adapting based on the project’s needs. Additionally, they allow for complex shapes that traditional methods may struggle to achieve. But, not all materials are suitable. Certain reflective metals can cause issues, leading to poor results.

Moreover, operational costs can be high. Maintenance and power consumption might deter some businesses. Training staff to operate these machines safely and efficiently is crucial. Investing in technology is wise, but it's essential to assess whether the high precision aligns with your manufacturing goals. The learning curve is steep, requiring time and experimentation.