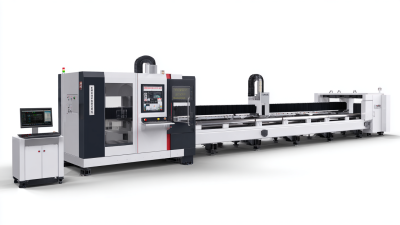

The manufacturing landscape is rapidly evolving, with precision and efficiency becoming paramount to meet the demands of modern industries. Iron Laser Cutting Machines have emerged at the forefront of this transformation, enabling manufacturers to achieve unmatched accuracy and speed in their production processes. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 6.8 billion by 2026, driven largely by innovations in iron laser cutting technology. These machines not only enhance productivity but also substantially reduce waste and operational costs. As industries strive for higher quality standards and lean manufacturing practices, the role of Iron Laser Cutting Machines becomes increasingly critical, positioning them as the future of precision manufacturing. Leveraging advanced laser technology, they offer versatile applications across sectors such as automotive, aerospace, and metal fabrication, making them an indispensable asset for forward-thinking manufacturers.

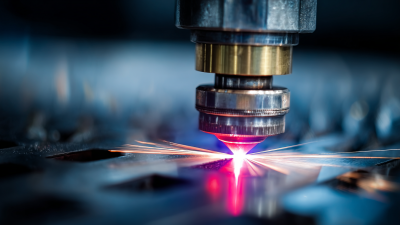

Iron laser cutting machines are revolutionizing precision manufacturing by offering unmatched benefits that cater to the demands of modern production. One of the primary advantages of these machines is their exceptional accuracy. With laser technology, manufacturers can achieve intricate designs and specifications that would be challenging to replicate using traditional cutting methods. This precision not only enhances the quality of the final products but also reduces material wastage, optimizing overall production efficiency.

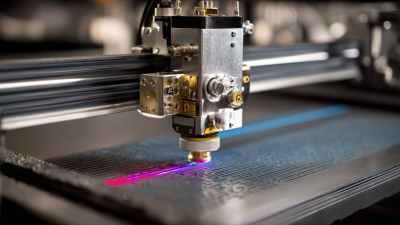

Moreover, iron laser cutting machines contribute to enhanced flexibility in manufacturing processes. They can easily adapt to varying project requirements, allowing for quick changes in design without the need for extensive retooling or setup. This adaptability is especially beneficial in industries where customization and rapid prototyping are essential. Additionally, the speed of laser cutting minimizes downtime, enabling manufacturers to meet tight deadlines while maintaining high standards of quality. Ultimately, the integration of iron laser cutting technology into precision manufacturing paves the way for more innovative and sustainable production methods.

Modern iron laser cutting technology stands at the forefront of precision manufacturing, driven by several key features that enhance its capabilities. One significant aspect is the type of laser used in these machines, with fiber lasers gaining popularity due to their efficiency, superior beam quality, and versatility in cutting various materials. In contrast, CO2 and solid-state lasers still hold a notable market share, catering to specific applications that leverage their unique properties, particularly in industries requiring high-powered cutting solutions.

The market dynamics have shifted as industries adopt automation and robotics, further enhancing production efficiency and precision. Semi-automatic systems offer flexibility for smaller production runs, while fully automated robotic cutting systems ensure high throughput in large-scale operations. Additionally, the COVID-19 pandemic showcased the resilience of the laser cutting sector, as manufacturers adapted to new operational challenges and maintained production continuity, illustrating the technology's pivotal role across various end-user industries, including automotive and electronics, especially in advancements such as silicon carbide semiconductor wafers. This innovation underscores the transformative potential of laser cutting machines in meeting the evolving demands of precision manufacturing.

Implementing iron laser cutting technology in your manufacturing facility can significantly enhance precision and efficiency. The first step in this process is to assess your current production methods and identify areas where laser cutting could provide benefits. According to a recent report by MarketsandMarkets, the laser cutting market is expected to grow from $4.0 billion in 2020 to $7.2 billion by 2026, reflecting an increasing trend toward automation and precision manufacturing. This data underscores the urgency for facilities to innovate and adopt cutting-edge technologies, like laser cutting, to stay competitive.

Once you've assessed your needs, the next step is to invest in suitable equipment that aligns with your production goals. Laser cutting machines offer various specifications based on power, speed, and accuracy. A comprehensive analysis by IBISWorld highlights that businesses using laser cutting machinery have seen a 30% reduction in material waste due to the precision of cuts, making it an environmentally friendly solution as well. Training your staff in operating these machines is crucial as well, ensuring they have the skills to maximize the benefits of this advanced technology. The integration of iron laser cutting not only streamlines processes but positions your manufacturing facility at the forefront of industry innovation.

The increasing reliance on laser cutting machines in precision manufacturing underscores their importance in optimizing production processes. To maintain the effectiveness of these machines, adopting best practices for maintenance is crucial. Regular cleaning of the optics, ensuring proper alignment, and monitoring the cooling system can significantly enhance the lifespan and performance of laser cutting equipment.

Tips: Always follow the manufacturer's guidelines for maintenance schedules and procedures. Invest in training for operators to recognize early signs of wear and tear, which can prevent costly downtime.

Optimization of laser cutting machines also involves leveraging advanced technologies. For instance, incorporating data analytics and machine learning can help fine-tune cutting parameters for improved efficiency and precision. Integrating these technologies not only streamlines operations but also reduces material waste, which is a key factor in modern manufacturing.

Tips: Consider using monitoring software to track machine performance in real-time, enabling quick adjustments to keep operations running smoothly. Regularly review and update cutting strategies based on material types and production demands for optimal results.

The rapidly evolving landscape of precision manufacturing is witnessing a transformative shift with the increased adoption of iron laser cutting machines. According to a report by MarketsandMarkets, the global laser cutting market is projected to grow from $4.3 billion in 2020 to $6.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.2%. This significant growth can be attributed to the efficiency and accuracy that laser cutting technology provides, particularly in the processing of materials such as iron.

As industries strive for greater operational efficiency, the precision offered by laser cutting systems is becoming indispensable. Laser cutting not only enables intricate designs with minimal material waste but also reduces the time required for cutting operations, which, as per a study by PwC, can lead to up to a 30% reduction in manufacturing costs. The ability to automate and customize the cutting process allows manufacturers to meet the increasing demands for complex components in various sectors, including automotive and aerospace. This trend positions iron laser cutting machines as a pivotal factor in enhancing manufacturing efficiency and competitiveness in the global market.

| Feature | Description | Benefits | Impact on Efficiency |

|---|---|---|---|

| Speed | Laser cutting machines operate much faster than traditional methods. | Increased production rates, reduced lead times. | Overall reduction in manufacturing time. |

| Precision | Offers high precision and accuracy in cutting. | High-quality cuts minimize material waste. | Improved product quality and consistency. |

| Flexibility | Can cut various shapes and materials with minimal adjustments. | Adaptability to various design requirements. | Faster response to design changes. |

| Cost-Effectiveness | Lower operational costs due to reduced material waste. | Better ROI for manufacturers. | Lower operating expenses enhance profitability. |

| Automation | Easily integrated with automated systems. | Reduces the need for manual intervention. | Streamlines operations and reduces labor costs. |