In today's fast-paced manufacturing landscape, the adoption of advanced technologies is critical for maintaining competitive advantage. Innovative Tube Cutting Machines are at the forefront of this evolution, drastically altering how manufacturers approach tube processing. According to a recent industry report by MarketsandMarkets, the global metal cutting machine market is projected to reach $8.3 billion by 2025, with tube cutting technologies playing a significant role in this growth. This surge is propelled by the rising demand for precision and efficiency in manufacturing processes across various sectors, including automotive, aerospace, and construction. As companies strive to reduce production time while enhancing quality, Tube Cutting Machines are becoming indispensable, offering capabilities such as automated cutting, increased speed, and reduced waste. This article will explore the transformative impact of these machines and provide a comprehensive guide on how to effectively implement them in modern manufacturing settings.

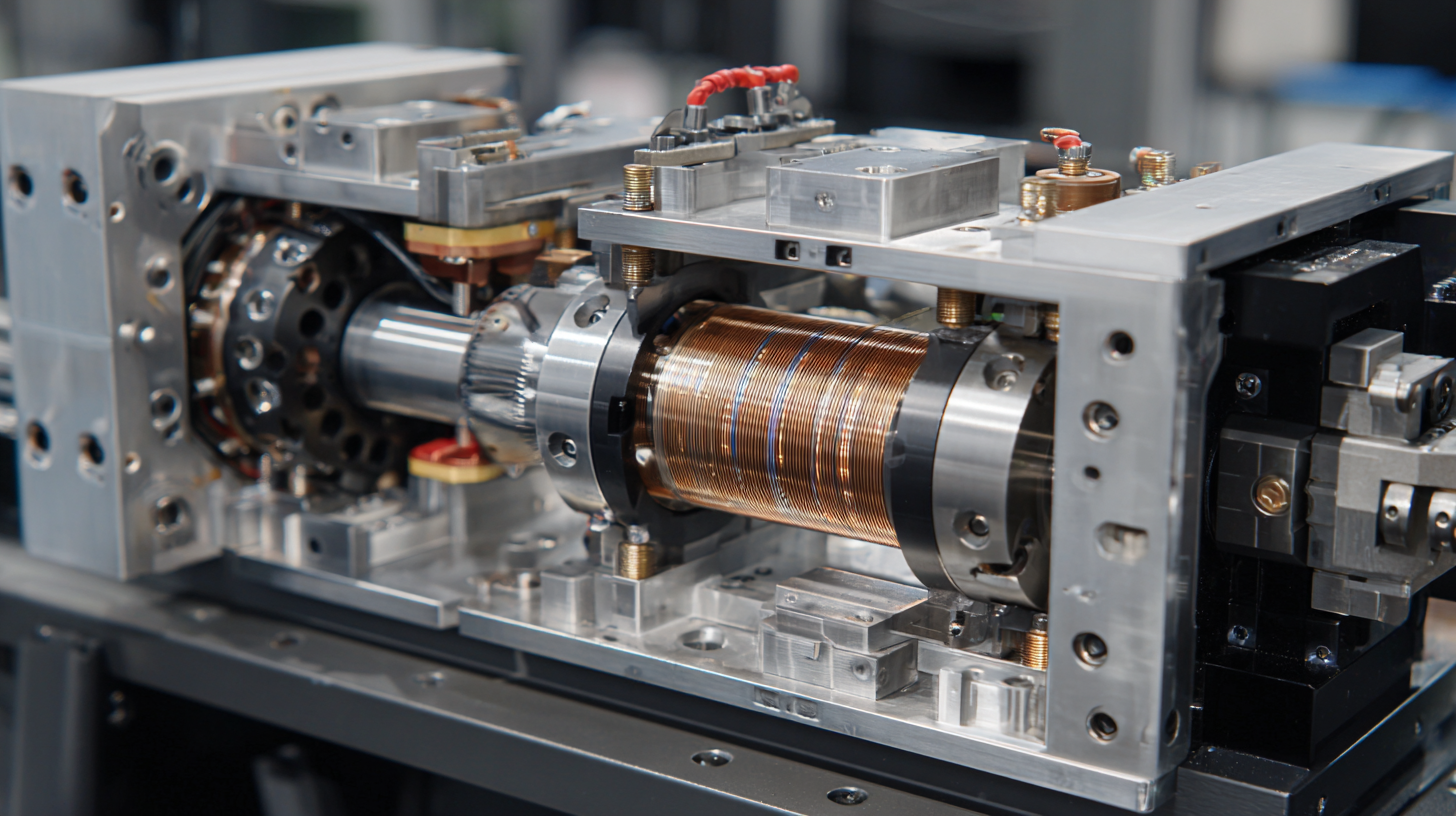

The emergence of smart technology has marked a significant turning point in the evolution of tube cutting machines, enhancing efficiency and precision in modern manufacturing processes. According to a recent report by MarketsandMarkets, the global market for smart manufacturing is expected to reach $600 billion by 2026, fueled by advancements in automation, big data analytics, and the Internet of Things (IoT). These innovations are enabling tube cutting machines to optimize their operation through real-time data analysis, predictive maintenance, and adaptive control systems, consequently reducing downtime and improving productivity.

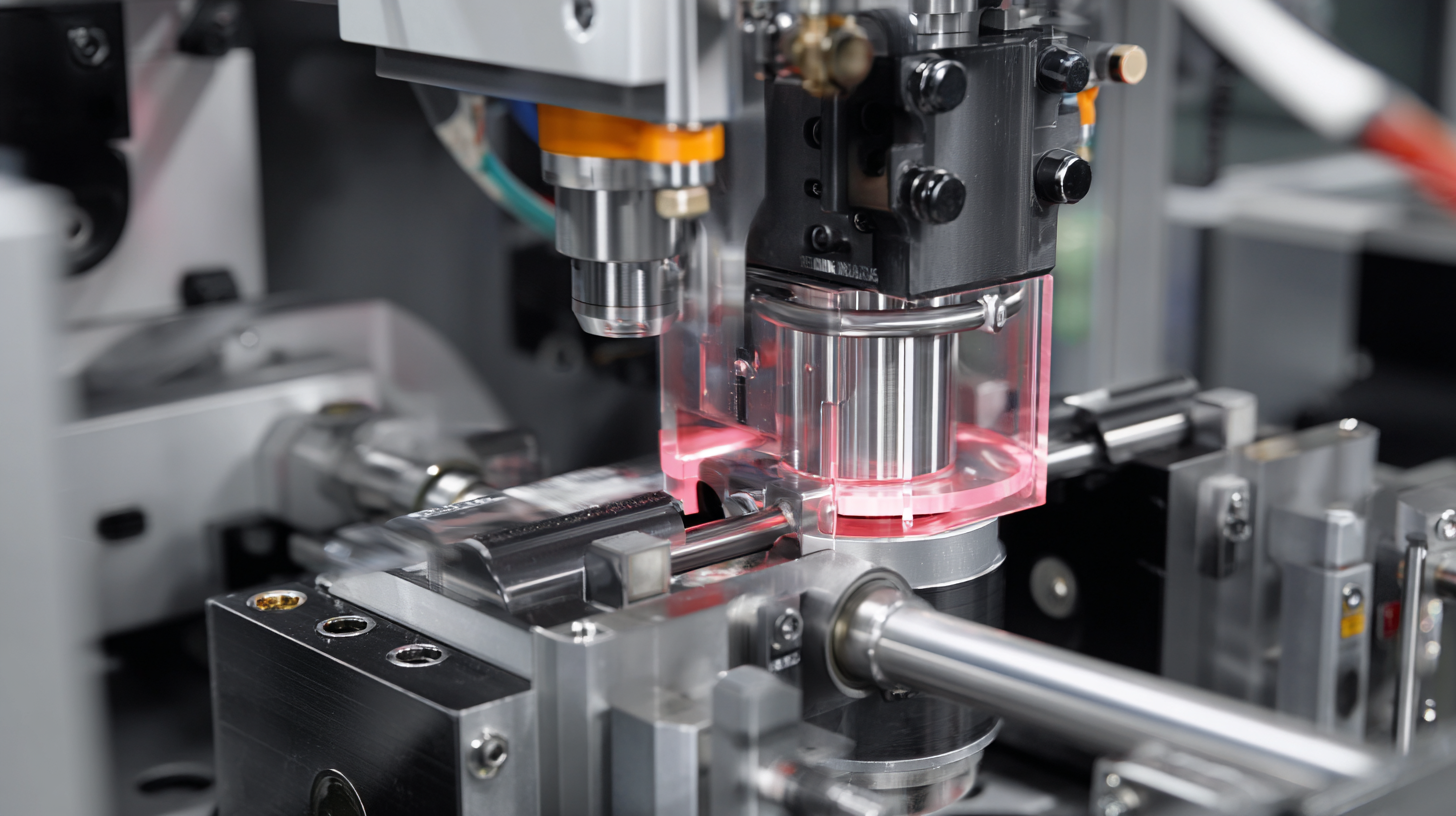

One of the hallmark features of the latest tube cutting machines is the integration of IoT capabilities, which allows for remote monitoring and control. A study by Grand View Research indicates that IoT-enabled machinery can increase operational efficiency by up to 30%. This technology not only streamlines the process but also enhances quality control through continuous feedback loops that can adjust cutting parameters on-the-fly. The result is not just faster manufacturing processes but also a drastic reduction in material waste—data shows that smart tube cutting can minimize scrap rates by as much as 15%, contributing to more sustainable manufacturing practices.

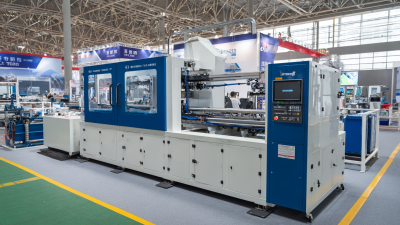

Innovative tube cutting machines are transforming the landscape of modern manufacturing by enhancing precision, efficiency, and flexibility in production processes. One of the key features that set these machines apart is their advanced automation capabilities. According to a report from MarketsandMarkets, the global automated machine tools market is projected to reach $96.3 billion by 2025, indicating a strong shift towards automated solutions in the manufacturing sector. These machines reduce manual labor, minimize human error, and significantly increase production speed, allowing manufacturers to meet growing demands with ease.

Another distinguishing feature is the integration of smart technology. Many of the latest tube cutting machines come equipped with IoT sensors that enable real-time data monitoring and analytics. This not only helps in predictive maintenance but also allows operators to monitor performance metrics continuously. A study by Grand View Research estimates that the global smart manufacturing market will reach $504.4 billion by 2025, highlighting the importance of incorporating smart technologies in machinery.

**Tip:** When considering an investment in tube cutting machines, look for models with advanced analytics and IoT capabilities to ensure they can adapt to future manufacturing needs effectively. Also, prioritize machines that offer customizable settings for different materials to enhance versatility in production.

| Feature | Description | Advantages | Applications |

|---|---|---|---|

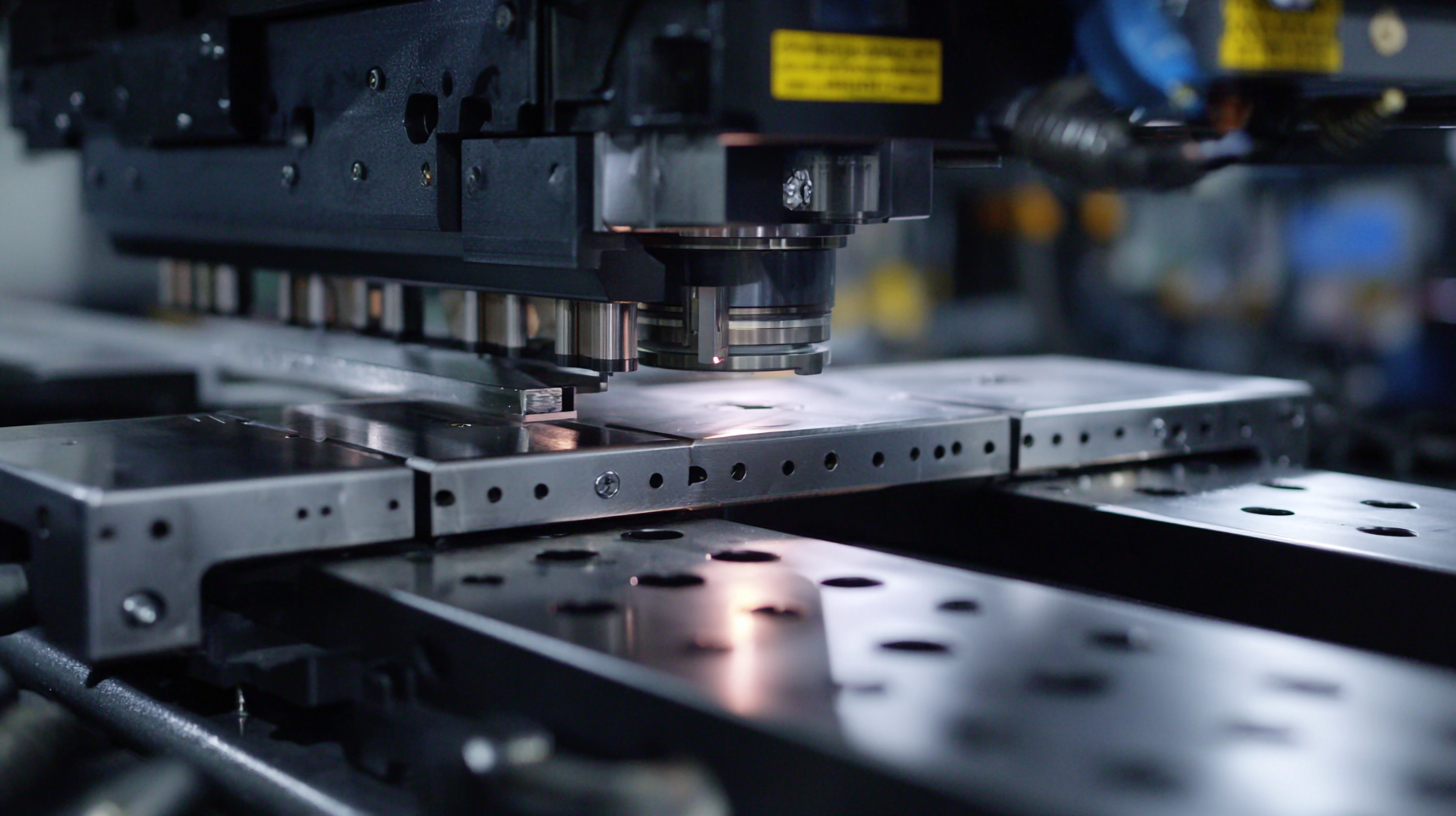

| Precision Cutting | Utilizes advanced lasers or saws for accurate cuts. | Minimizes material waste and ensures high quality. | Aerospace, automotive, and architecture. |

| Automated Operations | Integrates robotics for automated processing. | Increases efficiency and reduces labor costs. | High-volume manufacturing environments. |

| Versatility | Can cut a variety of materials such as metal, plastic, and composites. | Adapts to different project requirements easily. | Construction, industrial design, and art. |

| Enhanced Safety Features | Includes protective enclosures and emergency stops. | Reduces risk of accidents and operator injury. | All manufacturing environments. |

| Real-time Monitoring | Equipped with IoT technology for performance tracking. | Allows predictive maintenance and reduces downtime. | Smart factories and industrial IoT applications. |

The advent of innovative tube cutting machines has significantly transformed modern manufacturing processes, primarily through efficiency gains. These advanced machines leverage precision engineering and automation, allowing manufacturers to achieve higher productivity levels than ever before. By minimizing manual intervention and reducing the potential for human error, companies can streamline workflows and cut down on time spent on each job. This shift not only accelerates production schedules but also ensures consistent quality across all output.

Moreover, the integration of smart technology in tube cutting machines further enhances efficiency. Features such as real-time monitoring, adaptive cutting techniques, and data analysis capabilities enable manufacturers to optimize their operations. For instance, predictive maintenance tools can foresee machinery needs before a breakdown occurs, thus avoiding costly downtime. As a result, businesses can allocate resources more effectively, respond quickly to market demands, and ultimately improve their bottom line, positioning themselves competitively in the global market.

Sustainability has become a pivotal principle in the manufacturing industry, and eco-friendly practices are redefining tube cutting processes. Modern tube cutting machines have adopted innovative technologies that minimize waste and energy consumption. By employing advanced algorithms and precision cutting techniques, manufacturers can reduce scrap material significantly, ensuring that every piece of raw material is utilized efficiently. This not only lowers production costs but also lessens the environmental impact associated with traditional manufacturing methods.

Moreover, the incorporation of renewable energy sources into tube cutting operations highlights the industry’s commitment to sustainability. Solar and wind energy systems are increasingly being integrated into production lines, providing clean power to drive these advanced machines. Additionally, manufacturers are focusing on using biodegradable and recyclable materials, contributing to a circular economy where materials are reused and repurposed. These innovations not only promote environmental stewardship but also resonate with consumers who prioritize sustainability in their purchasing decisions, ultimately leading to a more responsible and eco-conscious manufacturing landscape.

This chart illustrates the percentage of tube cutting machines utilizing eco-friendly practices and innovations in the manufacturing sector over the last five years. It highlights the growing trend towards sustainability in manufacturing processes, showcasing the importance of innovation in reducing environmental impact.

The next generation of tube cutting technologies is poised to transform the manufacturing landscape, marked by increased precision, automation, and efficiency. Recent reports indicate that the global tube cutting machine market is expected to grow by over $2 billion by 2026, boosting an annual growth rate of over 5%. This growth is driven by advances in laser cutting and CNC technologies, which allow for intricate designs and faster production times. Companies are increasingly investing in smart manufacturing technologies that integrate IoT and AI capabilities, resulting in improved operational efficiencies and reduced waste during the cutting processes.

As manufacturers seek to enhance productivity, innovations such as adaptive cutting systems are emerging. These systems can analyze real-time data to adjust cutting parameters automatically, ensuring optimal performance regardless of material variance. Additionally, the integration of 3D modeling software is enabling designers to simulate and optimize their cutting processes before actual production, minimizing errors and reducing lead times.

With new materials like high-strength alloys and composites gaining traction in various industries, the ability to efficiently process these materials is crucial. The future of tube cutting technologies is not just about cutting; it’s about redefining how manufacturers approach design and production to meet the demands of an increasingly competitive market.