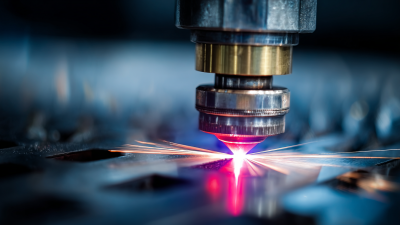

As the manufacturing landscape evolves, the adoption of advanced technologies such as the Metal Laser Cutting Machine has become essential for enhancing precision and efficiency in metalworking processes. According to a recent report by Technavio, the global market for laser cutting machines is expected to grow at a CAGR of over 6% from 2021 to 2025, driven by the increasing demand for automation and precision in various industries including automotive, aerospace, and electronics. The ability of metal laser cutting machines to provide high-quality cuts with minimal waste has positioned them as a preferred choice for manufacturers aiming to meet stringent quality standards while reducing operational costs.

This article presents 10 essential tips that will empower operators and engineers alike to master the intricacies of metal laser cutting technology, ensuring optimal performance and maximized production capabilities in a competitive marketplace.

Metal laser cutting machines have revolutionized the manufacturing industry, offering precision and efficiency that traditional cutting methods cannot match. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to grow from USD 3.1 billion in 2021 to USD 5.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 13.3%. This growth is driven by the increasing demand for advanced manufacturing processes and the ability to cut complex shapes in various materials, including steel, aluminum, and titanium.

Metal laser cutting machines have revolutionized the manufacturing industry, offering precision and efficiency that traditional cutting methods cannot match. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to grow from USD 3.1 billion in 2021 to USD 5.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 13.3%. This growth is driven by the increasing demand for advanced manufacturing processes and the ability to cut complex shapes in various materials, including steel, aluminum, and titanium.

Understanding the basics of how metal laser cutting machines operate is crucial for anyone looking to harness their potential. These machines use focused laser beams to melt, burn, or vaporize the material, resulting in extremely detailed cuts with minimal waste. The cutting speed can reach up to 1000 inches per minute, making them ideal for high-production applications. Furthermore, with advancements in technology such as fiber lasers, the efficiency and quality of the cutting process continue to improve, further solidifying their place in modern metal fabrication. Ensuring proper maintenance and operating protocols can enhance the lifespan of these machines, making informed training and operational guidelines essential for maximizing productivity.

Choosing the right laser cutting machine is crucial for maximizing productivity and efficiency in metal fabrication. With advancements in technology, today's laser systems offer features that enhance the cutting process. For instance, simultaneous pick-and-place technology can significantly increase throughput by automating loading and unloading tasks. This is particularly beneficial for high-production environments, where the return on investment (ROI) can potentially be seen within six months to a year.

When selecting a laser cutter, consider the specific requirements of your projects. The power and capabilities of the machine should align with the materials you intend to work with. For example, high-power lasers, while offering advantages in speed and cutting thickness, may not be necessary for all applications. Understanding nesting fundamentals is also essential; inefficient material arrangement can lead to instability during the cutting process. As the demand for faster and more accurate cutting solutions continues to rise, making informed decisions is vital for manufacturers looking to optimize their operations.

Operating metal laser cutting machines requires stringent safety measures to protect both the operator and the equipment. One of the most crucial safety precautions is to always wear appropriate personal protective equipment (PPE). This includes safety glasses with protective lenses, gloves, and steel-toed boots, which will safeguard against laser light and potential debris. Additionally, ensure that your work environment is well-ventilated to avoid inhaling harmful fumes generated during cutting.

Another essential tip is to conduct a thorough inspection of the laser cutter before use. Check for any loose connections or damaged components, as these could lead to malfunctions or accidents during operation. It's vital to familiarize yourself with the emergency shut-off procedures of the machine. In case of an emergency, you need to act quickly to minimize risks.

Lastly, maintaining a clean workspace free of flammable materials is critical to ensuring safety while operating laser cutters. Keep the area organized, avoiding unnecessary clutter that could lead to hazardous situations. By following these essential safety precautions, operators can enhance their efficiency and ensure a safer working environment while mastering the art of metal laser cutting.

Maintaining metal laser cutting machines is crucial for ensuring their longevity and efficiency in high-precision manufacturing. According to a recent report by Industry Research, regular maintenance can extend the lifespan of laser cutting equipment by up to 25%. This emphasizes the importance of routine checks, as even minor neglect can lead to significant downtimes and costly repairs.

One essential tip is to keep the optics clean; dirty lenses can drastically reduce cutting quality and lead to increased energy consumption. Implementing a cleaning schedule every few weeks can maintain optimal performance.

Another vital aspect is the cooling system. Laser cutting machines generate substantial heat during operation, and proper cooling management is essential to prevent overheating. Research indicates that maintaining a consistent coolant temperature can improve system efficiency by as much as 30%. It's advisable to check coolant levels regularly and replace them as needed to ensure the system operates smoothly. Additionally, monitoring airflow through the equipment can prevent dust accumulation that may impair performance, leading to potential failures. Adopting these maintenance strategies can not only enhance efficiency but also significantly extend the machine's operational life.

In the realm of metal laser cutting, efficiency is paramount, and avoiding common mistakes can significantly enhance operational productivity. One major pitfall is neglecting the importance of machine calibration. According to a report by the Fabricators & Manufacturers Association, improper calibration can lead to deviations in cutting precision, resulting in wasted materials and increased production costs. Ensuring that the machine is calibrated regularly not only preserves the quality of the cuts but also extends the lifespan of the equipment.

Another common mistake occurs during the setup phase, particularly in selecting the appropriate type and thickness of material. A survey conducted by the Laser Institute of America revealed that 30% of production errors stemmed from using unsuitable materials for laser cutting. Operators often overlook the specified parameters for each material, leading to suboptimal cutting speeds and excessive heat input, which can affect the integrity of the cut. By understanding the compatibility of different materials with laser cutting technology, manufacturers can achieve superior results and minimize rework.