The landscape of manufacturing is rapidly evolving, and the Cnc Laser Cutting Machine is at the forefront of this change. In 2026, we expect several exciting trends to shape the industry. These machines, known for their precision and efficiency, will likely adopt more advanced technologies. Enhanced automation is one such trend, enabling faster production with minimal human intervention.

Another notable change is the growing emphasis on eco-friendliness. Manufacturers are increasingly concerned about their carbon footprint. Cutting machines will need to reflect this shift, possibly incorporating renewable energy sources. Additionally, the integration of AI into Cnc Laser Cutting Machines could improve operational efficiency. Smart technology may help predict maintenance needs and reduce downtime.

However, challenges persist. The pace of innovation is rapid, leaving some businesses struggling to keep up. Balancing performance with affordability is a critical concern. As these trends unfold, it will be essential for companies to adapt and innovate continually. The future of Cnc Laser Cutting Machines is bright, yet full of hurdles that demand attention.

As we look toward 2026, emerging materials for CNC laser cutting are reshaping the industry. Advanced composites, with their lightweight and durable properties, are gaining traction. According to industry reports, the market for advanced materials is projected to grow by over 12% annually. These materials can offer significant advantages in applications like aerospace and automotive manufacturing.

Metallic materials are also evolving. Steel remains a staple, but new alloys are entering the scene. These alloys exhibit enhanced strength and corrosion resistance. Some reports indicate that the adoption of these materials could reduce production costs by as much as 20%. This shift will likely challenge traditional welding methods.

Plastics are undergoing transformations too. The rise of engineered thermoplastics presents exciting possibilities. Their versatility allows for more complex designs, which traditional methods struggle with. With a projected market increase of 10% by 2026, the potential is substantial. However, the challenge remains in achieving precision during the cutting process. Manufacturers must invest in training and technology to meet these demands.

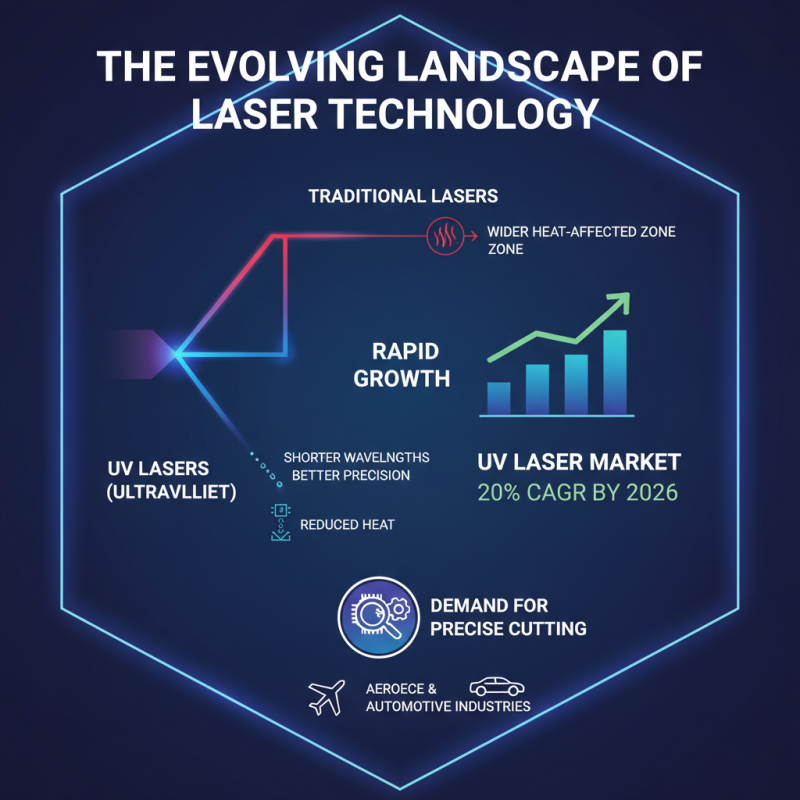

The landscape of laser technology is evolving rapidly. One of the critical areas to watch is the advancement in wavelengths. Shorter wavelengths, such as ultraviolet (UV) lasers, are growing in popularity. They provide better precision and reduced heat-affected zones. According to a report by ResearchAndMarkets, the UV laser market is expected to grow at a CAGR of 20% by 2026. This growth reflects increased demand for more precise cutting in industries like aerospace and automotive.

Power levels are another significant trend. Higher power levels enable faster cutting speeds and improved efficiency. Recent advancements suggest power levels exceeding 20 kW are becoming mainstream. This shift allows for cutting through thicker materials with ease. A report indicates that the high-power laser cutting market is anticipated to reach over $2 billion by 2026. Yet, there are challenges to consider. Managing operational costs and energy efficiency remains a concern.

As companies adopt these new technologies, they must reflect on their production processes. The excitement of automation and speed should not overshadow the importance of quality and precision. Balancing these factors will be crucial for sustainable growth in this competitive landscape.

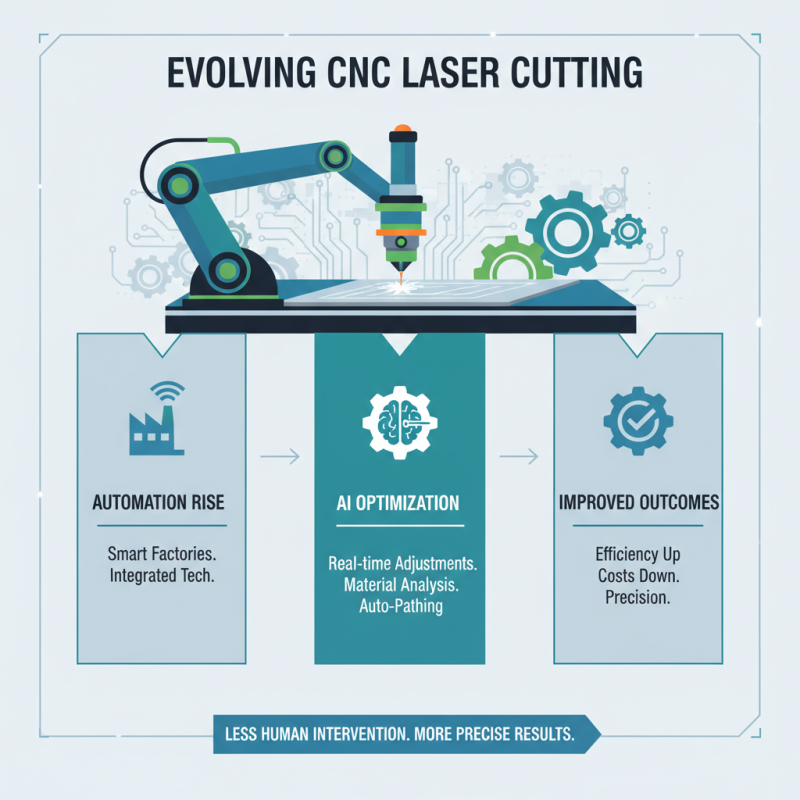

The landscape of CNC laser cutting is evolving rapidly. One major trend is the rise of automation. Factories are looking to integrate smart technologies into their processes. This shift leads to improved efficiency and reduced labor costs. Machines equipped with AI can adjust settings in real-time. They analyze material quality and optimize cutting paths automatically. This means less human intervention and more precise results.

Yet, the journey toward fully automated systems is complex. Many companies struggle with initial integration costs. Training staff to work alongside new technologies can also be challenging. The technology is advancing faster than some businesses can adapt. It's crucial to strike a balance between automation and human oversight. Machines must be reliable, but human skills retain value. The danger lies in over-reliance on technology without critical assessment.

As factories embrace smart systems, they should not overlook potential pitfalls. Security risks with interconnected devices are a concern. Data breaches can disrupt operations significantly. Addressing these vulnerabilities is essential for sustainable growth. Embracing automation is beneficial, but a cautious approach is necessary. Awareness and adaptation will ultimately dictate success in the ever-advancing CNC laser cutting landscape.

The shift towards sustainability in CNC laser cutting is becoming increasingly vital. Companies are now considering eco-friendly practices in their operations. The emphasis is on recycling materials and minimizing waste. Using renewable energy sources is gaining traction as manufacturers seek to reduce their carbon footprint. This shift not only benefits the planet but also improves the bottom line.

Implementing recycling practices can be tricky. Some materials are not easy to recycle. Companies must invest in proper waste separation tools. Educate your team on sorting materials effectively. More awareness leads to better recycling outcomes. Adjustments in processes may require trial and error.

Another important trend is the use of biodegradable materials. They can perform well under laser cutting conditions. Still, they need careful handling and application. Integration requires testing new materials. This can cause initial disruptions in production. Nevertheless, blending innovative materials can make a significant impact over time. Keeping an open mind leads to potential breakthroughs.

This chart illustrates the top trends in CNC laser cutting machines projected for 2026. It highlights the focus on sustainability, showcasing the influence of recycling practices, eco-friendly materials, energy efficiency, automation integration, and waste reduction in shaping the future of CNC laser cutting technologies.

The CNC laser cutting industry is set for remarkable growth in 2026. Innovations in technology will drive change. This sector is rapidly evolving, with increased demand for precision cutting. Industries such as automotive and aerospace will rely more on CNC lasers. These machines offer higher efficiency and improved accuracy. Users are looking for reliable equipment that can handle diverse materials.

A key trend is automation in CNC laser cutting. Automated systems enhance productivity and reduce labor costs. However, not all companies can adapt quickly. Some face challenges in integrating new technologies. Training staff and managing the transition is crucial. The initial investment may also pose a hurdle. Despite these challenges, the potential for cost-saving and higher output is significant.

Sustainability will also shape the landscape. Companies are searching for eco-friendly practices. This includes reducing waste and improving energy efficiency. However, achieving these goals requires careful planning. Not every business is ready to invest in greener options. This may hinder progress in the long run. The CNC laser cutting market holds promise, but reflections on capability and resources are essential for success.