In today's competitive manufacturing landscape, efficiency and precision are paramount to the success of any production process. Among the various technological advancements available, the CNC Fiber Laser Cutting Machine has emerged as a game changer for manufacturers looking to enhance their operational capabilities. This innovative cutting solution harnesses the power of fiber laser technology to deliver exceptional cutting speed and accuracy, allowing businesses to produce intricate designs with minimal material waste.

The shift towards CNC fiber laser cutting not only optimizes the quality of finished products but also significantly reduces lead times, making it an ideal choice for both small-scale and large-scale manufacturing operations. With the ability to cut through a wide range of materials, including metals, plastics, and composites, this versatile machine caters to diverse industry requirements. As manufacturers strive to keep pace with evolving market demands, investing in a CNC Fiber Laser Cutting Machine proves to be a strategic decision that ensures both reliability and long-term growth.

CNC fiber laser cutting machines are rapidly becoming a cornerstone in modern manufacturing due to their numerous advantages over traditional cutting methods. One of the significant benefits is their unparalleled precision and speed. According to a report by the International Data Corporation (IDC), fiber laser technology can achieve cutting speeds up to 30% faster than conventional CO2 lasers while offering a cutting accuracy of ±0.01 mm. This precision allows manufacturers to produce intricate designs that meet stringent quality standards, ultimately leading to reduced waste and higher efficiency in production processes.

Furthermore, CNC fiber laser cutting machines are known for their versatility. They can cut a wide array of materials, from metals like stainless steel and aluminum to composites and plastics. Industry data from MarketsandMarkets indicates that the demand for fiber laser cutting technology is expected to grow at a CAGR of 8.5% through 2025, driven by advancements in materials and applications. This adaptability makes fiber lasers ideal for various sectors, including automotive, aerospace, and electronics, where customization and quick turn-around times are critical for competitive advantage.

Another notable advantage is the lower operational costs associated with fiber lasers. Unlike traditional lasers, fiber lasers use significantly less energy and require minimal maintenance, translating into lower operational costs for manufacturers. According to a study by Fraunhofer ILT, the energy consumption of fiber lasers can be up to 70% less than that of CO2 lasers, leading to considerable savings over time. This not only enhances the profit margins for manufacturers but also aligns with the growing industry emphasis on sustainability and eco-friendly practices.

When selecting a CNC fiber laser cutting machine for your manufacturing needs, several key features should be taken into account to ensure optimal performance and efficiency. One of the primary factors to consider is the laser power. Reports indicate that machines with higher wattage, such as those ranging from 1000W to 4000W, can significantly enhance cutting speeds and capabilities, particularly when working with thicker materials. A machine with the appropriate power rating can lead to a 30% increase in productivity, which is crucial for manufacturers looking to meet tight deadlines without compromising quality.

Another critical feature is the machine's cutting area. The size of the cutting bed can greatly affect the types of projects you can undertake. For instance, a larger workspace can accommodate bigger sheets of material, reducing waste and setup time. Industry studies suggest that companies utilizing machines with larger cutting areas can improve their operational efficiency by up to 20%. Additionally, consider the machine's automation capabilities; automated systems not only enhance precision but also significantly reduce labor costs, with some companies reporting as much as a 50% reduction in manual intervention when using advanced automation technologies.

Lastly, it is essential to evaluate the machine's software integration and user interface. A user-friendly interface can facilitate easier operation and programming, thereby reducing training times for operators. Furthermore, seamless integration with CAD/CAM software is vital, as it can streamline the design-to-production workflow. As per recent industry analyses, manufacturers that effectively utilize sophisticated software tools alongside their CNC fiber laser cutters report a 25% increase in efficiency, highlighting the importance of this feature in modern manufacturing environments.

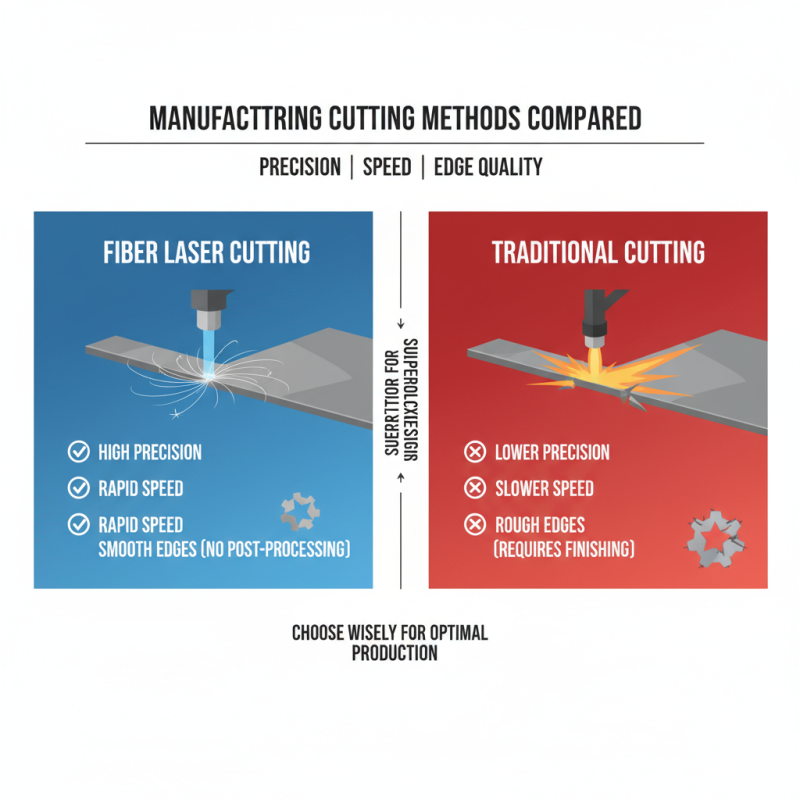

When considering manufacturing processes, it's essential to understand the differences between fiber laser cutting and traditional cutting methods. Fiber laser cutting machines utilize a focused beam of light to cut through materials with high precision and speed, making them ideal for projects requiring intricate designs and tight tolerances. In contrast, traditional methods such as plasma or mechanical cutting may struggle with complex geometries and can lead to rougher edges, requiring additional finishing processes that can increase production time and costs.

One significant advantage of fiber laser cutting is its efficiency with various materials, including metals, plastics, and wood. This versatility allows manufacturers to adapt quickly to changing market demands without investing in multiple cutting technologies. Additionally, fiber lasers generate less heat during the cutting process, which mitigates the risk of warping or damaging the material being cut. Traditional methods, on the other hand, often produce excessive heat that can lead to thermal effects on sensitive materials, which may compromise the quality of the end product.

Furthermore, fiber laser systems typically result in lower operational costs over time. They consume less energy compared to traditional cutting machines, and their maintenance requirements are often less demanding due to the lack of physical cutting tools that wear out. This leads to a more streamlined manufacturing process, reducing downtime and improving overall productivity while ensuring high-quality results. The choice between fiber laser and traditional cutting methods ultimately hinges on the specific needs of the manufacturing project, but the numerous advantages of fiber lasers make them a compelling option for modern production environments.

CNC fiber laser cutting technology is widely utilized across a variety of industries due to its precision and efficiency. In the automotive sector, for instance, the ability to cut intricate designs into metals and other materials allows manufacturers to produce parts with exact specifications. This precision not only enhances the performance and safety of vehicles but also reduces material waste, making the manufacturing process more sustainable.

Another significant application is found in the aerospace industry, where lightweight yet strong components are essential. CNC fiber laser cutting machines can handle tough materials such as titanium and aluminum, enabling manufacturers to produce complex geometries that meet stringent regulations. Additionally, the technology is also making waves in the signage industry by allowing for the creation of detailed and vibrant designs that stand out, while in the electronics sector, it facilitates the production of components with high accuracy, ensuring that devices function optimally. The versatility of CNC fiber laser cutting continues to transform manufacturing processes across these diverse fields.

When considering the manufacturing landscape today, investing in a CNC Fiber Laser Cutting Machine stands out as a cost-effective solution that promises long-term savings. Unlike traditional cutting methods, fiber laser technology allows for more precise cuts with minimal waste, significantly decreasing material costs. The efficiency of these machines not only reduces energy consumption but also shortens production time, leading to lower operational costs overall. This means that companies can achieve more in less time, maximizing their resources and enhancing profitability.

Tips for manufacturers looking to adopt fiber laser technology include conducting a thorough cost analysis to understand potential savings over time. Investing in a machine that suits your production volume and material types can bring substantial returns. Additionally, regularly maintaining the laser machine ensures optimal performance, extending its lifespan and further reducing costs associated with repairs and downtime.

Furthermore, consider training staff to operate the CNC fiber laser cutting machine effectively. Proper training can enhance productivity and minimize errors, as skilled operators can troubleshoot and optimize operations. Embracing this technology not only positions a manufacturer to stay competitive but also opens the door to innovative applications that drive growth and efficiency in the ever-evolving manufacturing industry.