Selecting the right Laser Machine for your business is a crucial decision that can significantly influence your operational efficiency and profitability. According to a recent industry report from the International Market Analysis Research and Markets, the laser processing market is expected to reach over $20 billion by 2025, underscoring the growing demand for precise and versatile laser machinery across various sectors.

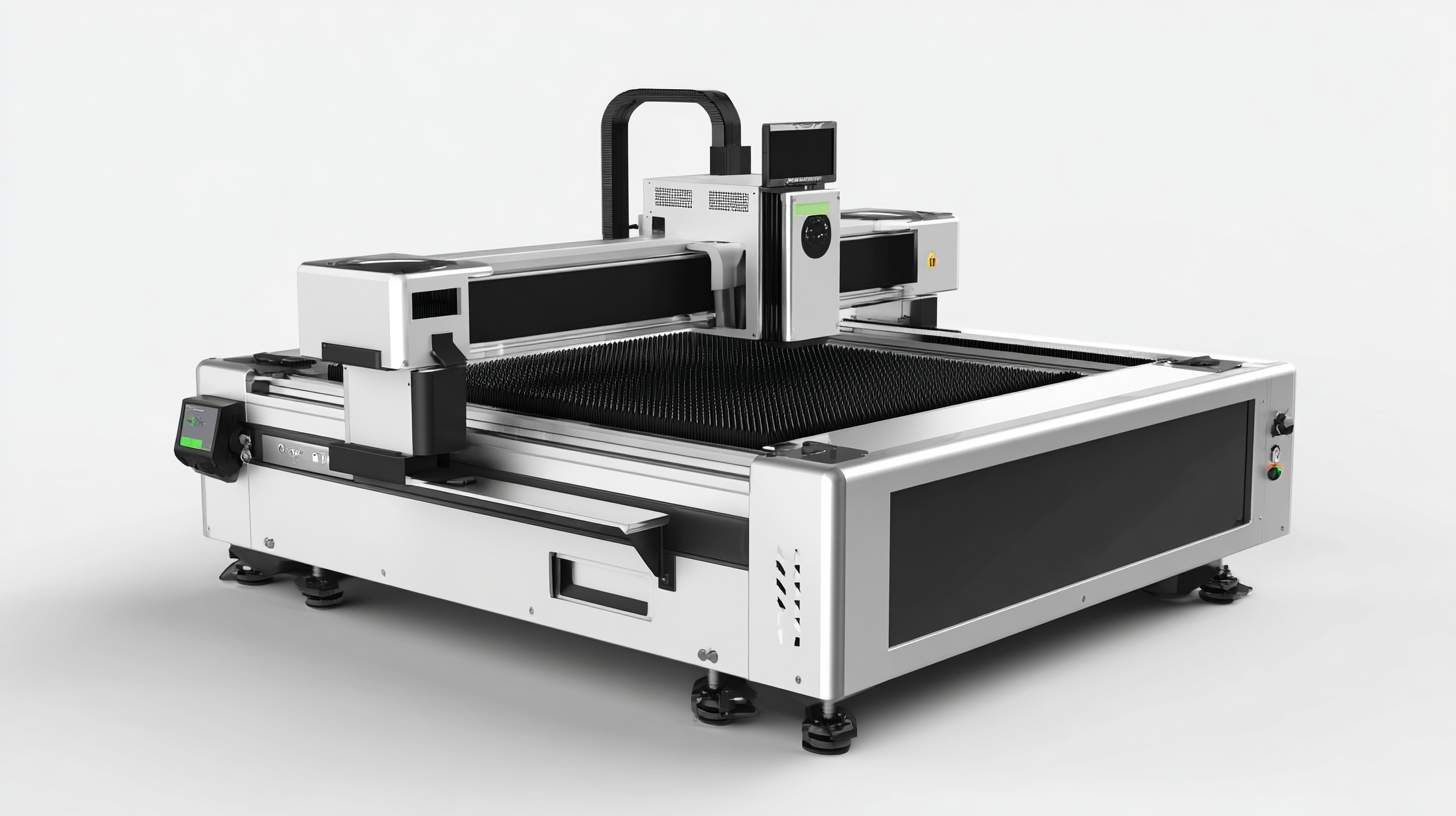

As businesses strive for automation and innovation, it's imperative to choose a laser machine that fits specific production needs, whether in manufacturing, fabricating, or even artistic applications. Factors such as material compatibility, machine maintenance, and return on investment must be carefully examined to ensure optimal performance and productivity.

As businesses strive for automation and innovation, it's imperative to choose a laser machine that fits specific production needs, whether in manufacturing, fabricating, or even artistic applications. Factors such as material compatibility, machine maintenance, and return on investment must be carefully examined to ensure optimal performance and productivity.

This guide aims to provide insights and considerations to help you navigate the complexities of selecting the most suitable laser machine for your business needs.

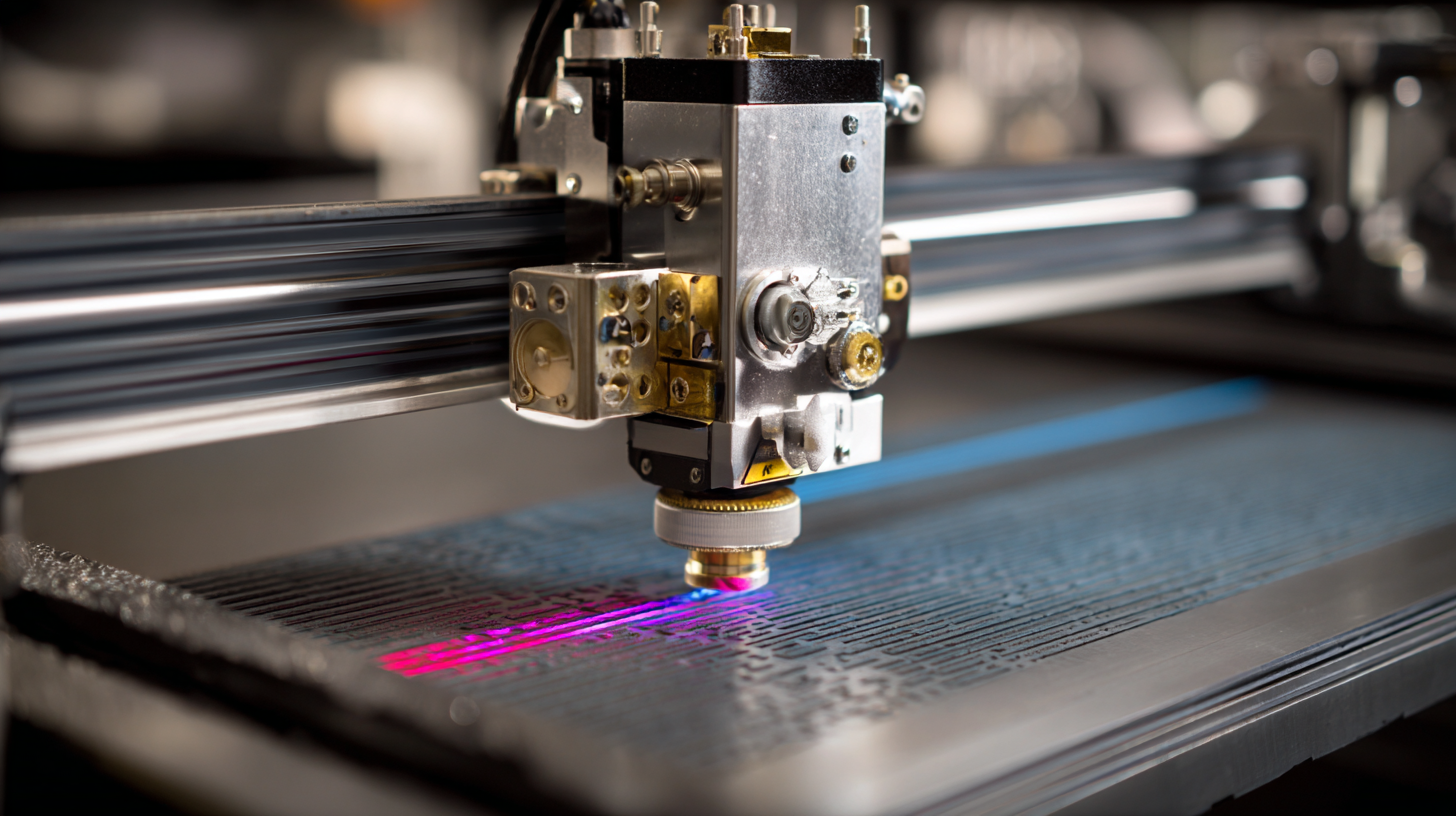

When considering the right laser machine for your business, it is essential to understand the different types available and their specific applications. CO2 laser machines are highly versatile and commonly used for cutting and engraving non-metal materials such as wood, acrylic, and leather. Their ability to produce intricate designs makes them ideal for crafts and signage, allowing businesses to cater to creative markets.

On the other hand, fiber laser machines excel in cutting and marking metal materials with precision. They are known for their speed and efficiency, making them suitable for industries like automotive, aerospace, and manufacturing. Selecting a fiber laser is particularly beneficial if your business primarily works with metals, as these machines can handle thick materials and deliver high-quality results. Each type of laser machine has its unique strengths, and aligning these with your specific business needs will ensure optimal performance and productivity.

When selecting a laser machine for your business, evaluating power and speed is crucial, as these key performance metrics directly impact the efficiency and quality of your production. The power of a laser, measured in watts, determines its ability to cut through materials and perform intricate designs. Higher wattage typically allows for cutting thicker materials and faster processing times, while lower wattage machines may be more suited for detailed engraving work on softer materials.

When selecting a laser machine for your business, evaluating power and speed is crucial, as these key performance metrics directly impact the efficiency and quality of your production. The power of a laser, measured in watts, determines its ability to cut through materials and perform intricate designs. Higher wattage typically allows for cutting thicker materials and faster processing times, while lower wattage machines may be more suited for detailed engraving work on softer materials.

Tip: Assess your primary applications before purchasing. If your business focuses on high-volume cutting of thicker materials, a higher power laser machine is essential. Conversely, for precision engraving on delicate materials, opt for a machine that offers fine control at lower speeds.

Speed is another vital consideration. It refers to how fast the laser head moves across the material. While speed can enhance productivity, it’s important to find a balance as too high a speed may compromise cutting quality.

Tip: Choose a machine with adjustable speed settings, allowing you to optimize for different materials and projects. Testing various speed levels on sample materials can help you determine the best settings for achieving your desired results while maintaining efficiency.

When selecting a laser machine for your business, it's crucial to consider the financial implications beyond just the initial purchasing cost. A comprehensive cost analysis should weigh the initial investment against long-term operational expenses. While a more expensive laser machine may seem daunting at first, it often comes with superior technology, better energy efficiency, and lower maintenance costs, ultimately leading to higher productivity and lower operating fees.

Tips: Look for a laser machine that offers good warranty terms and support services. This can help mitigate unforeseen operational costs if something goes wrong. Additionally, consider the energy consumption rates of different machines since this will directly affect your operational expenses over time.

Another key factor to consider is the availability of replacement parts and consumables. A machine that is easy to maintain can save you valuable time and money in the long run. Research various brands and models, focusing on the total cost of ownership rather than just the sticker price to make an informed decision that aligns with your business needs.

When selecting a laser machine for your business, maintenance and support should be a top priority. According to a recent report by MarketsandMarkets, the global laser cutting machine market is expected to grow significantly, with a CAGR of 6.5% from 2020 to 2025. This growth indicates that businesses are increasingly recognizing the importance of advanced machinery. However, owning a high-quality laser cutter isn’t just about the initial investment; it’s essential to choose a manufacturer who offers reliable support and maintenance services to ensure machine longevity and optimal performance.

Inadequate support can lead to increased downtime, affecting production efficiency and profitability. A survey conducted by the Laser Institute of America revealed that 42% of businesses experienced significant losses due to unplanned machinery downtime, highlighting the critical need for responsive maintenance solutions. When researching manufacturers, consider their service offerings, such as training programs, on-site support, and regular maintenance check-ups. Companies that provide comprehensive service plans not only help extend the lifespan of the equipment but also empower your staff with the knowledge to operate the machines effectively, ultimately enhancing your production capabilities.

As businesses increasingly embrace technology to enhance productivity, the significance of laser technologies cannot be understated. Industries ranging from manufacturing to healthcare are experiencing a transformation driven by advancements in laser applications. High-precision laser cutting, engraving, and marking are becoming crucial in sectors where accuracy and efficiency are paramount. The emerging trend of integrating automation with laser systems further amplifies their potential, enabling businesses to streamline operations and reduce production costs.

The impact of these technologies on business growth is profound. Companies adopting advanced laser solutions find themselves with a competitive edge, as they can meet rising customer demands for customization and speed. Furthermore, the versatility of lasers allows businesses to diversify their offerings, tapping into new markets and opportunities. As companies assess their needs, understanding the latest trends in laser technology will play a vital role in determining the right equipment to invest in, ultimately shaping their future success in an evolving market landscape.

| Industry | Laser Technology | Application | Growth Potential (%) | Cost Range ($) |

|---|---|---|---|---|

| Manufacturing | CO2 Laser | Cutting & Engraving | 10-15% | 5,000 - 30,000 |

| Healthcare | Fiber Laser | Surgery & Treatment | 15-20% | 20,000 - 150,000 |

| Aerospace | YAG Laser | Welding & Repair | 8-12% | 15,000 - 100,000 |

| Automotive | Nd:YAG Laser | Cutting & Marking | 12-18% | 10,000 - 50,000 |

| Construction | Diode Laser | Leveling & Measuring | 5-10% | 1,000 - 10,000 |