Choosing the right CNC Fiber Laser Cutting Machine is crucial for modern manufacturing. Many factors come into play. These machines offer precision and efficiency. However, the best choice is not always obvious.

You might be swayed by flashy features or low prices. It's essential to think about your specific needs first. Consider the materials you will work with. Each machine handles different thicknesses and types of metal. Not all options fit every job.

A machine's speed and power are also vital. Too often, buyers overlook these details. Reflect on long-term costs besides upfront payments. Maintenance and support should not be an afterthought. Investing wisely can elevate your production capabilities significantly.

CNC fiber laser cutting technology has revolutionized precision manufacturing. This process employs a focused laser beam to cut through various materials. The result is clean edges and intricate designs. Unlike traditional cutting methods, the heat-affected zone is minimal. This leads to less warping and distortion in the material.

Operating a CNC fiber laser machine requires knowledge and skill. Users must understand the settings required for different materials. Each material behaves uniquely when exposed to the laser. Mistakes can happen if adjustments are not made properly. It’s crucial to conduct tests before final production runs. Sometimes, the calibration is off. This could lead to unexpected results, which can be frustrating.

Moreover, maintenance plays a significant role in the performance of these machines. Regular cleaning of lenses and mirrors is essential. Neglecting this task can result in reduced efficiency. It's a common oversight that could affect output quality. Users must be diligent in their upkeep practices to avoid long-term issues. The balance between technology and hands-on experience remains essential in this field.

When selecting a CNC fiber laser cutting machine, the first key factor is the power level. Power affects the cutting speed and the thickness of the materials. A machine with higher wattage can cut through thicker metals faster. However, more power means higher costs. It’s essential to find a balance that suits your production needs without overspending.

Another crucial consideration is the size of the bed. The size determines how large your workpieces can be. A larger bed allows for bigger projects, but also takes more shop space. Consider your workspace layout carefully before choosing. Additionally, pay attention to the machine's software compatibility. Good software can streamline your workflow but can require additional training.

Lastly, think about the support and maintenance options. A reliable support team can save time and potentially costly downtime. Evaluate the warranty terms carefully. It’s necessary to reflect on long-term needs and possible upgrades. Choosing a machine is not just an investment in equipment; it’s a commitment to your production future.

When choosing a CNC fiber laser cutting machine, evaluating power and performance specifications is crucial. The power output of the machine significantly impacts the cutting speed and material thickness. Higher wattage machines cut through thicker materials quickly, but they can be more expensive. Lower wattage options may suffice for lighter tasks but can slow processes down.

Tips: Consider the materials you’ll work with most frequently. If you only cut thin sheets, a lower power model can save costs. If versatility is key, opt for something in the mid-range.

Performance specs, such as speed and accuracy, also play a vital role. Faster machines reduce production time, but speed shouldn’t compromise precision. A balance is essential for efficient production. Evaluate how often you need to switch between materials. Frequent changes can affect workflow efficiency.

Tips: Always check reviews and user feedback on performance accuracy. Sometimes, machines with high specs lack real-world efficiency. Remember, even the best machines require maintenance. Regular upkeep prolongs life and ensures peak performance. Your choice should meet both current demands and future needs.

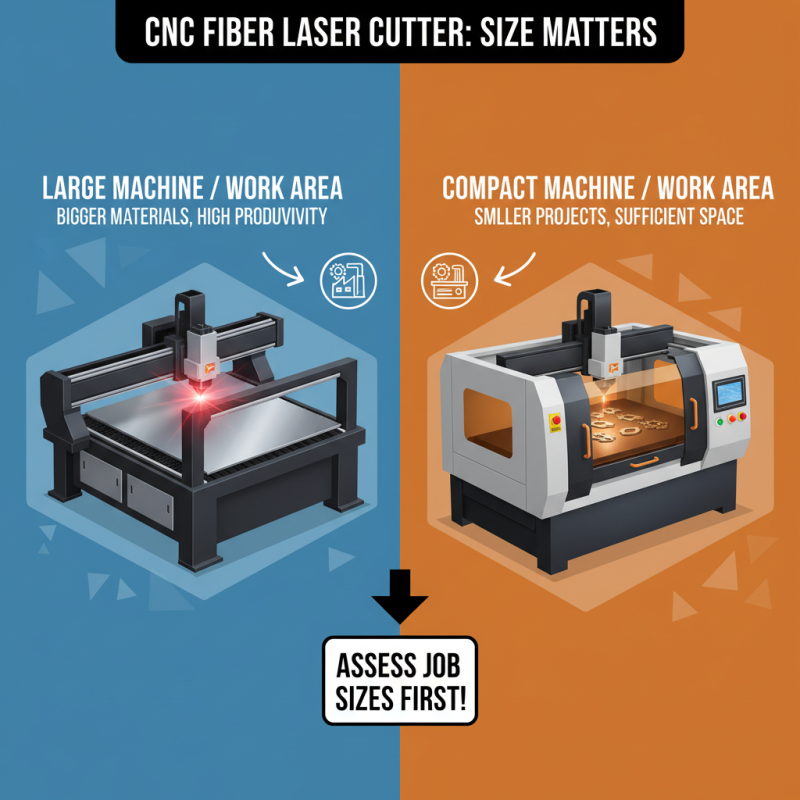

When choosing a CNC fiber laser cutting machine, machine size and work area are crucial. A larger work area allows for bigger materials. This can enhance productivity. However, if your projects are smaller, a compact machine might suffice. It is important to assess your typical job sizes first.

Consider the space available in your workshop. A large machine requires more room, which might not be feasible in smaller setups. You might feel tempted to buy a bigger machine for future projects. Yet, if space is tight, this could lead to inefficiencies. Evaluate whether you can maneuver materials easily around the machine.

Also, think about the workflow. A machine that fits well in your space can streamline operations. If staff need to move around the machine, ensure there’s adequate space. Reflecting on your current and future needs is essential. Selecting the right size is not just about specifications; it involves practical considerations too.

When selecting a CNC fiber laser cutting machine, understanding the budget is crucial. The initial purchase price is just one piece of the puzzle. Maintenance costs can add up over time. Regular upkeep is essential for optimal performance. Consider the costs associated with replacement parts and labor. It’s not merely about the sticker price.

Long-term operational costs play a significant role as well. Energy consumption can vary greatly between machines. A more efficient model may have a higher upfront cost but lower energy bills. Operating hours can also affect the overall expenditures. Machines that are more reliable can ultimately save money. Downtime for repairs could lead to lost revenue.

Reflect on what you truly need. Sometimes, it’s easy to get caught up in advanced features. However, ask yourself: will they really benefit you? Focus on practical requirements. Avoid decisions based on flashy specifications that might not be necessary. Each small detail in your budget adds up. Understanding these factors now can lead to better choices in the future.