In today's fast-paced manufacturing landscape, choosing the right CNC cutting machine is crucial. According to Dr. Emily Carter, a leading expert in CNC technology, "Selecting the right machine can save time and enhance precision." This statement emphasizes the importance of informed decision-making in the CNC industry.

When evaluating a CNC cutting machine, consider specific requirements such as material type and thickness. Different machines excel in different tasks. For instance, some excel at cutting metals, while others are better for wood or plastics. It's critical to match your project needs with the machine's capabilities. This will ensure efficiency and accuracy in your work.

Many buyers overlook the significance of after-sales support and maintenance. A machine may boast top specifications but could underperform without proper service. Users often assume they know what they need. Reflecting on past mistakes can guide future purchases. Ultimately, understanding the nuances of CNC cutting machines is necessary for success in your projects.

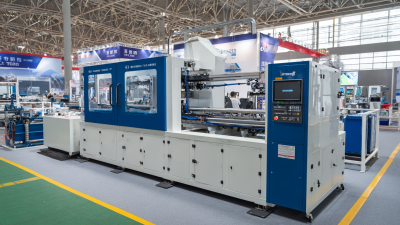

CNC cutting machines play a pivotal role in various industries, including manufacturing, woodworking, and metalworking. They come in different types—laser, plasma, waterjet, and router. Each serves specific purposes. For instance, laser cutting machines excel at precision work and can cut through thin materials easily. Plasma cutters, on the other hand, are favored for thicker metals but may lack finesse on delicate tasks.

Industry reports indicate a growing demand for CNC cutting machines, projected to reach USD 8 billion by 2026. This growth is fueled by automation and the need for efficiency. However, selecting the right CNC machine poses challenges. Many companies fail to analyze their specific needs, leading to mismatched equipment choices. For example, what works in woodworking scenarios may not suit metal fabrication.

Applications of CNC machines vary widely. In automotive manufacturing, these machines ensure intricate designs and precise components. However, not all CNC machines can handle multiple materials. This limitation can become apparent when projects need sudden adjustments. Investing wisely, based on application and material requirements, is crucial. Misjudgments can result in operational setbacks or increased costs.

Choosing the right CNC cutting machine is crucial for efficiency and quality. Several key factors come into play when making this decision. The type of material you will cut is essential. Different machines excel with various materials, such as wood, metal, or plastic. Understanding these requirements can improve your production.

Another important consideration is the machine's size and working area. Ensure the dimensions fit your workspace and meet your project needs. A compact machine may save space, but it might limit your capabilities. Think carefully about your long-term needs.

**Tips:** Always measure your workspace before purchase. This ensures a good fit. Also, factor in future projects. You do not want to outgrow your machine too soon. Finally, consider your budget. Striking a balance between quality and cost can be tricky. Evaluate what features you can live without.

When selecting a CNC cutting machine, evaluating cutting precision and material compatibility is crucial. Precision is often quantified in terms of tolerances. High-quality machines typically achieve tolerances within +/- 0.01 mm, while lower-end models might only reach +/- 0.1 mm. Choosing a machine with the necessary precision can significantly affect your end product quality, especially in industries like aerospace and automotive where standards are stringent.

Material compatibility is another vital aspect. Different materials require specific cutting methods. For instance, metal requires a different approach compared to wood or plastic. According to industry reports, 70% of users face challenges aligning their machines with the right materials for optimal performance. If a machine is not suited for the material's properties, it can lead to increased wear and tear or even tool failure. Adjusting settings becomes critical. Operators must have thorough knowledge of not only the machine but also the materials they are processing.

Additionally, many machines struggle with diverse cutting tasks. A one-size-fits-all approach doesn't work. This limitation can hinder productivity and lead to wasted resources. Lengthy adjustments and incorrect settings may surface, creating frustrations. Understanding how your chosen machine interacts with various materials is essential for avoiding these pitfalls. Assessing these factors early can save time and costs, ultimately driving better results.

When choosing a CNC cutting machine, assessing your budget and total cost of ownership is crucial. The initial price can be misleading. Many buyers focus solely on the purchase price without considering additional costs. Maintenance, consumables, and operational expenses can add up quickly. A machine might seem affordable, but hidden costs can impact long-term ROI.

Consider the power consumption of the CNC machine. Machines that are energy-efficient can save money over time. However, cheaper machines might consume more energy. Evaluate the expected lifespan of the machine too. A lower upfront cost might lead to more downsides in repairs and replacements later.

Don’t overlook factors like operator training. Investing in skilled personnel can enhance productivity. Additionally, think about space and setup costs. A machine that fits well in your workshop can save costs on alterations. Reflect on these aspects to make a well-rounded decision. An impulsive choice can lead to regret and overspending. Always review all potential expenses before making a final choice.

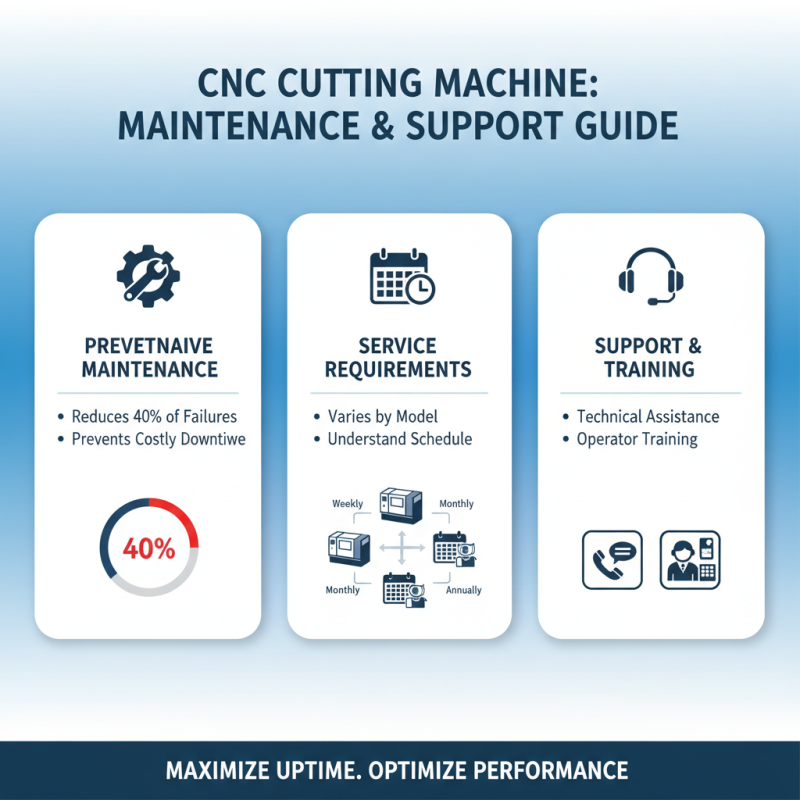

When selecting a CNC cutting machine, maintenance and support are critical aspects to consider. Data from industry reports indicate that about 40% of machine failures stem from inadequate maintenance. Regular service can prevent costly downtimes. Understanding the maintenance requirements of your chosen model is essential. Some machines demand more frequent servicing than others.

Tip: Keep a maintenance schedule to ensure longevity. Document every service and minor repair. This habit can save you time and money in the long run.

Support options also play a significant role. Many manufacturers offer varying levels of customer support. According to a 2022 survey, 56% of users prefer machines with robust technical support. Consider how quickly a manufacturer can respond in case of machine failure. This can make a significant difference in operational efficiency.

Tip: Evaluate online reviews and case studies of support experiences. They can provide insights into how companies handle service requests. Choosing a machine without considering these factors may lead to unexpected challenges.