Choosing the right metal laser cutting service can be challenging. Many factors come into play. Quality, precision, and cost are essential. You want a service that meets your specific needs, not just the lowest price.

When selecting a metal laser cutting service, consider your project's requirements. Look for a company with advanced technology and skilled operators. Their equipment should handle various materials without compromising quality. However, it's crucial to realize that capabilities vary among service providers. Some may not meet high standards consistently.

Pay attention to customer reviews and past projects. This will give you insight into their reliability. Sometimes, even reputable companies can make mistakes. Communication is vital. Be clear about your expectations. Understanding the nuances of metal laser cutting can help avoid potential issues. Through careful selection, you can find a service that ensures both quality and satisfaction.

Understanding your metal cutting needs is vital for selecting the right service. Begin by evaluating the type of metal you require. Are you working with steel, aluminum, or perhaps copper? Each material has unique properties. This affects how it can be cut. Knowing your material helps narrow down potential services.

Once you identify the metals, think about the thickness. Different thicknesses require different laser capabilities. A service that excels at thin sheets may struggle with heavier materials. Ask yourself how precise the cuts need to be. Some projects demand intricate designs, while others may focus on simpler shapes. Reflect on your overall project goals and expectations.

It's also important to consider batch sizes. Are you looking for prototypes or mass production? Some services specialize in large orders, while others cater to custom, one-off pieces. Understand your timeline too. Some providers have faster turnaround times, but may sacrifice quality. Balancing speed and quality is essential. Be prepared to adjust your expectations as you explore your options.

When choosing a metal laser cutting service, evaluating the experience and expertise of service providers is crucial. Look for companies with a strong track record in the industry. Experience often translates to better quality. A provider with years in business likely understands various materials and cutting techniques well.

Ask for examples of past projects. This can reveal their level of expertise. Did they handle complex designs? Were they able to meet tight deadlines? Each completed project speaks volumes about a service provider's capability. Additionally, consider their staff qualifications. Knowledgeable technicians can make a difference in the outcome.

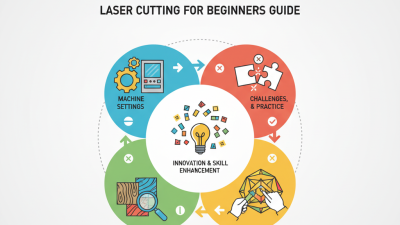

It's also wise to check references. A reputable provider should be open to sharing client feedback. Keep in mind that a shiny marketing pitch isn’t everything. Real-world outcomes matter. The ability to adapt and problem-solve is equally important. After all, innovation in laser cutting can lead to unique designs better suited for specific needs.

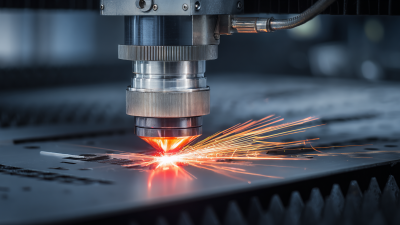

Choosing the right metal laser cutting service can be challenging. Understanding the technology and equipment they use is crucial. Different machines produce various qualities and finishes. High-powered lasers can cut thicker materials, but may not be suitable for intricate designs. Lower-powered devices excel at precision but limit material thickness.

It’s essential to explore the types of lasers available. CO2 lasers are popular for cutting non-metal materials but can also handle metalwork. Fiber lasers offer superior cutting speed and efficiency for a variety of metals. Each type of laser has its strengths and weaknesses.

**Tips:** Look for services that provide samples of their work. This helps to assess the quality of their cuts. Discuss your project details clearly. Miscommunication can lead to unforeseen issues. Don't hesitate to ask about the cooling systems and maintenance of the equipment; this can affect delivery times and overall service reliability.

| Service Provider | Laser Type | Max Material Thickness (mm) | Positioning Accuracy (mm) | Max Cutting Speed (m/min) | Service Area |

|---|---|---|---|---|---|

| Provider A | Fiber Laser | 20 | 0.05 | 30 | North America |

| Provider B | CO2 Laser | 15 | 0.1 | 25 | Europe |

| Provider C | Fiber Laser | 10 | 0.03 | 35 | Asia |

| Provider D | Nd:YAG Laser | 12 | 0.1 | 20 | South America |

| Provider E | Fiber Laser | 25 | 0.05 | 40 | Australia |

When assessing metal laser cutting services, customer support stands as a critical factor. A responsive support team can make a significant difference. If you have questions about the cutting process, a good service should provide clear answers. Quick responses indicate that your needs will be prioritized. Technical issues should be dealt with promptly, ensuring minimal downtime.

Quality control is equally important. A service should have strict measures in place. For example, they might conduct regular inspections of their machinery. This ensures precision and consistency in the cutting process. Ask about their quality assurance protocols. Knowing how they handle defects can reveal their commitment to excellence. Sometimes, even reputable services might overlook certain details. It’s okay to inquire about past mistakes and how they rectified them.

In addition, evaluate testimonials from previous clients. Genuine feedback can highlight areas of strength and weakness. Look for comments on both service and support. This will help form a well-rounded view. If a company is not attentive to its customers, that could reflect on their overall work quality.

This bar chart represents the satisfaction ratings for various factors related to metal laser cutting services, including quality control, customer support, delivery time, response time, and pricing. The ratings are based on a scale of 1 to 10, indicating the level of customer satisfaction for each aspect.

When selecting a metal laser cutting service, pricing and turnaround time are crucial factors. Understanding how different providers structure their costs helps in making an informed decision. Typically, pricing depends on factors like material thickness, complexity of design, and volume of work. Always ask for a detailed quote. Some services may appear cheaper but have hidden fees.

Turnaround time is equally important. It varies widely among service providers. Some may promise a quick turnaround but compromise on quality. Others take longer but deliver precise cuts. It is vital to clarify timelines upfront. Have clear timelines in mind that fit your projects.

Tips: Prioritize your needs. If speed is essential, communicate that upfront. Ask about rush services. Keep an eye on quantities, as bulk orders often come with discounts. However, if the project is complex, lower volume might lead to better quality. Reflect on the balance between cost and quality — the cheapest option might not always be the best.