As the demand for precision and efficiency rises, choosing the right CNC Fiber Laser Cutting Machine becomes crucial for manufacturers. The global CNC laser cutting market is projected to reach $4.4 billion by 2026, according to a report by MarketsandMarkets. This growth reflects the industry's shift towards advanced technologies. However, with various options available, selecting the most suitable machine can be overwhelming.

Industry expert Dr. Emily Chen stated, "Investing in the right CNC Fiber Laser Cutting Machine can significantly impact productivity and quality." Her insights highlight the importance of understanding specific needs, such as material types and thicknesses. Each application presents unique challenges, and reflecting on these requirements will lead to better decision-making.

Additionally, one must consider long-term support and maintenance. Not all machines are created equal. Some may promise high speed but fall short on durability. Balancing initial costs with future performance is essential. Reflecting on these factors can guide operators toward a machine that aligns with their operational goals.

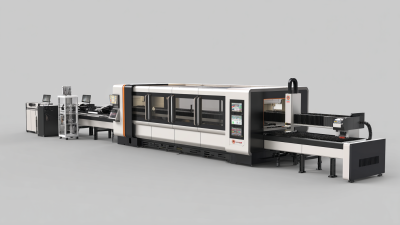

CNC fiber laser cutting technology is revolutionizing manufacturing. It uses concentrated laser beams to cut various materials with precision. Unlike traditional methods, this technology offers cleaner cuts and less waste. The process is fast and efficient, ideal for high-volume production.

Understanding how CNC fiber laser cutting works is crucial for making the right choice. The lasers create intense heat that melts the material. A gas blows away the molten parts, leaving clean edges. You may encounter settings that seem too complicated. However, once you grasp the basics, the process becomes more manageable.

Not all machines are equal, and performance varies widely. Some may not cut thicker materials well. Reflecting on your specific needs is essential. Consider material types and thicknesses most used in your projects. This technology offers great potential, but the learning curve can be steep. Embracing that challenge can lead to excellent results.

Choosing the right CNC fiber laser cutting machine can be challenging. There are many factors to evaluate. Consider your materials; different machines perform better on metals, plastics, or wood. Think about your production volume, too. A small workshop might not need the same capacity as a large factory.

Speed and precision are critical. Machines vary in speed, influencing overall efficiency. Accuracy is essential for detailed designs. Ensure the machine can maintain precise cuts, even at high speeds. Don't overlook software compatibility. A user-friendly interface will save you time. If the software is complex, training may be necessary.

Lastly, budget plays a significant role. High-quality machines come with a higher price tag. Determine your budget before shopping around. Sometimes, spending less can lead to shortcomings. Maintenance costs also add up. Evaluate these aspects carefully to make the best decision for your specific needs.

When selecting a CNC fiber laser cutting machine, it’s essential to analyze your specific cutting needs. Start by identifying the materials you frequently work with, such as metal, plastic, or wood. Different machines have varied capabilities for handling these materials. For example, a powerful laser will cut through thicker metal. Conversely, a machine optimized for wood may not handle metal as efficiently.

Tips: Always consider the thickness of the material. It often dictates the machine’s effectiveness. Ensure the laser's wattage aligns with your application. Don’t overlook the importance of speed. The faster the cutting process, the higher your productivity.

It’s important to consider your production scale. Are you a small workshop or a large manufacturing unit? Your choice of machine might differ greatly based on this aspect. Reflect on the versatility of the machine. Can it be adjusted for different projects? Machines that offer flexibility may save costs in the long run. Sometimes, a machine that seems perfect might lack practical features you need.

| Dimension | Specifications | Applications | Material Compatibility | Average Cost |

|---|---|---|---|---|

| Desktop | 500W, Compact Design | Small Parts, Prototyping | Aluminum, Brass | $10,000 - $15,000 |

| Mid-size | 1000W, Standard Size | Automotive Parts, Sheet Metal | Steel, Stainless Steel | $20,000 - $30,000 |

| Industrial | 2000W, Heavy Duty | Large Production Runs | Carbon Steel, Copper | $45,000 - $70,000 |

| High-Power | 4000W and Above | Thick Material Cutting | Titanium, High-strength Alloys | $90,000 and Up |

When selecting a CNC fiber laser cutting machine, comparing brands is crucial. Numerous options flood the market. Each brand offers different features, prices, and support. According to industry reports, the CNC laser cutting machine market is projected to grow by 6% annually between 2022 and 2029. This indicates a competitive landscape where brand choice matters.

While features like cutting speed and precision are vital, warranty and customer support also rank high. Not all brands excel in service after the sale. This is where users often face challenges. A report highlighted that 30% of businesses felt unsupported after purchasing. This gap underscores the importance of thorough research.

Tips: Look for brands with robust service options. Ensure they offer training and easy access to technical support. Additionally, read reviews and case studies to understand real-world performance. Don’t overlook the importance of machine maintenance either. A well-maintained machine can significantly extend its lifespan, and some brands may not clearly communicate this. Investigate carefully and don’t rush into a decision. Choose wisely; it could define your production efficiency and quality.

When budgeting for a CNC fiber laser cutting machine, keep in mind that costs can vary significantly. Industry reports show that high-quality machines can range from $30,000 to over $200,000. This wide range reflects features and capabilities. For instance, basic models may cut thinner materials but lack speed. Advanced models can handle thicker substrates and operate more efficiently.

Consider operational expenses as well. Regular maintenance and consumables add to the budget. According to studies, annual upkeep can be about 10% of the initial investment. This often goes unnoticed during the purchasing phase. It's crucial to assess the total cost of ownership over time.

Reflecting on your specific needs is essential before making a decision. For example, a shop focused on high-precision components may benefit from a more expensive, feature-rich machine. In contrast, a business with lower production demands might find greater value in a budget-friendly option. Balancing performance and cost will lead to better long-term investment choices.