In the evolving landscape of metal fabrication, Iron Laser Cutting Machines have emerged as an essential tool for precision engineering. According to the latest industry report by MarketsandMarkets, the global laser cutting machine market is projected to reach $5.2 billion by 2025, highlighting growing demand. Experts believe that these machines are vital for enhancing efficiency and reducing waste in metalworking.

Renowned industry specialist, Dr. James Harrow, emphasizes, “Iron Laser Cutting Machines not only improve accuracy but also empower manufacturers to innovate.” This reflects a broader trend where companies are investing heavily in advanced technologies. However, it’s crucial to reflect on the challenges that accompany this transition. Many manufacturers struggle with high initial costs and the need for skilled operators.

Despite these struggles, investing in an Iron Laser Cutting Machine can significantly streamline production. Precision is key in today's competitive market. Ensuring that each cut meets exact specifications is not just a goal, but a necessity. As technology advances, companies must adapt or risk falling behind. The journey to integration may be complex, but the rewards are substantial.

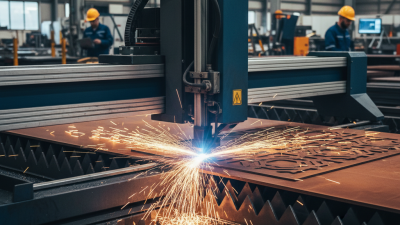

In the realm of metal fabrication, precision is paramount. Laser cutting machines crafted for iron offer remarkable accuracy. They excel at producing intricate designs and components with minimal waste. These machines often feature advanced technologies. High-speed cutting improves productivity significantly. A powerful laser beam ensures clean edges, reducing the need for extra finishing work.

When considering such machines, evaluating key features is essential. Focus on cutting speed, power, and control options. Some models allow for thicker materials, while others shine with delicate tasks. Furthermore, user-friendly interfaces can enhance the overall experience. However, these devices may require a learning curve. Users should invest time in understanding the operation and maintenance needs. Mistakes can happen, leading to costly repairs or material loss.

Benefits extend beyond mere cutting capability. These machines provide consistency in production, which is vital for quality control. They often include safety features to minimize accidents. However, the initial investment can be hefty. It’s crucial to weigh the efficiency gains against this cost. Finding the right balance can be a challenge, but the rewards are significant.

When selecting an iron laser cutting machine, understanding technical specifications is crucial. Cutting speed, laser power, and precision play vital roles in metal fabrication efficiency. Many models vary in these characteristics. Some machines can cut through thick metal sheets, while others excel at detailed designs.

Laser power often ranges from 500W to 4000W. This affects cutting speed and material thickness capabilities. For example, a 1000W machine may handle 10mm steel, but a 3000W model can slice through thicker materials quicker. Precision is another key point. Machines offer different resolutions that determine the detail of cuts. A high precision rate brings smoother edges, which may be necessary for intricate work.

Not all machines provide consistent performance. Users occasionally report varying results, especially when materials differ. Some models may struggle with layered or rusty surfaces. This inconsistency requires careful consideration. It's essential to evaluate the specific requirements of each project and match them with the machine's capabilities. Balancing power, precision, and material types ensures better outcomes in metal fabrication.

When it comes to iron laser cutting machines, three key factors influence performance: power, speed, and precision. The power of the machine dictates its ability to cut through thicker materials. Higher power levels mean faster cutting speeds but can also lead to rougher edges. Striking a balance is crucial.

Speed is another critical factor. A faster machine can increase productivity. However, if it's too fast, the quality may suffer. It’s essential to find the optimal speed for each specific cutting task. Some materials react better at different speeds, making adjustments necessary for achieving the best results.

**Tip:** Regular maintenance can enhance both power and speed. Keep lenses clean for optimal performance.

Accuracy is vital in metal fabrication. Precise cuts minimize material waste and improve the overall quality of the finished product. Small adjustments in settings can make a significant difference. Operators should have a good understanding of their machine's capabilities.

**Tip:** Experiment with settings on scrap materials before beginning production. This helps prevent costly mistakes.

Every machine has its quirks. Learning from each cutting session can help operators refine their techniques. Embracing imperfections can lead to improved strategies and outcomes over time.

| Model | Power (W) | Cutting Speed (m/min) | Max Thickness (mm) | Precision (mm) |

|---|---|---|---|---|

| Model A | 1500 | 20 | 10 | 0.1 |

| Model B | 2000 | 25 | 12 | 0.08 |

| Model C | 1000 | 18 | 8 | 0.15 |

| Model D | 2500 | 30 | 15 | 0.05 |

| Model E | 3000 | 35 | 20 | 0.03 |

Investing in industrial laser cutting machines can be a significant commitment. It's crucial to conduct a thorough cost analysis before making a choice. These machines come with a variety of operating costs, from initial purchase price to maintenance expenses. A basic model might look appealing, but hidden costs often surface later. Incorrect assumptions can lead to financial regret.

Return on investment (ROI) is another key consideration. How long will it take to recoup your initial costs? This varies widely. Efficient machines can greatly enhance productivity. However, they might demand higher upfront costs. Assessing your production volume is essential. Will the investment yield enough savings?

Moreover, the learning curve for these machines can be steep. Training staff might require additional funds. Mismanagement of resources can erode savings. Consider the long-term impacts on your operations. Some companies overlook this aspect, only realizing too late the need for skilled operators. Balancing costs and gains is vital.

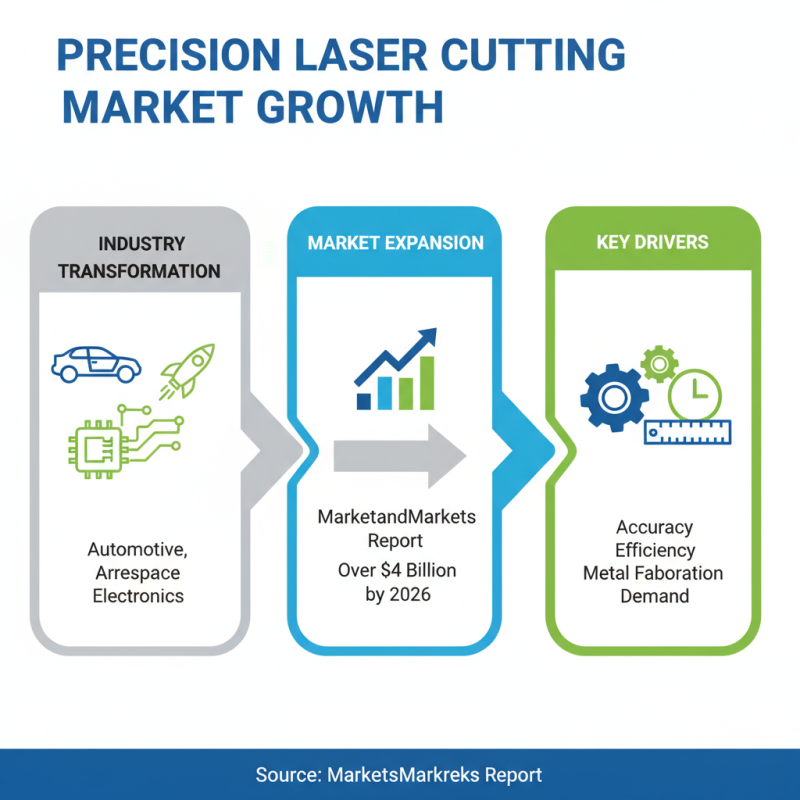

Precision laser cutting has transformed industries like automotive, aerospace, and electronics. A report from MarketsandMarkets highlights that the laser cutting market is expected to grow significantly. By 2026, it might reach a market value of over $4 billion. Such growth displays the increasing demand for accuracy and efficiency in metal fabrication.

In the automotive sector, laser cutting allows for sharper designs and reduced waste. For example, laser systems can cut complex shapes in steel with precision under 0.1 mm tolerance. This level of accuracy helps manufacturers meet strict safety and design standards. Conversely, this technology can be a double-edged sword. If not calibrated correctly, machines can produce unexpected results, leading to costly rework.

The aerospace industry also benefits immensely from laser cutting. Using laser technology, manufacturers can achieve intricate designs for lightweight structures. This is crucial for improving fuel efficiency and performance. However, precision comes at a cost. These machines demand skilled operators to ensure optimal performance. Unexpected machine failures can halt production lines, underscoring the need for ongoing maintenance and training.