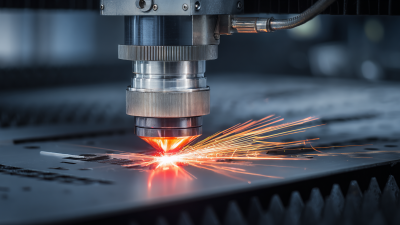

As the manufacturing industry evolves, the adoption of advanced technologies has become crucial for maintaining a competitive edge. Among these technologies, the CNC Laser Cutting Machine stands out as a transformative solution, capable of delivering precision and efficiency in material processing.

According to a recent report by MarketsandMarkets, the global CNC laser cutting machine market is projected to grow from $3.37 billion in 2021 to $5.89 billion by 2026, showcasing an impressive compound annual growth rate (CAGR) of 11.4%. This growth is driven by the increasing demand for accurate and high-speed cutting solutions across various sectors, including automotive, aerospace, and electronics.

In 2023, choosing the right CNC Laser Cutting Machine is more critical than ever. With advancements in laser technology, manufacturers have access to machines that not only enhance cutting speed and quality but also incorporate automation features that streamline production processes. The integration of smart technology allows for better control and monitoring, ultimately reducing waste and increasing profitability. As businesses navigate an ever-evolving marketplace, the decision to invest in a high-quality CNC laser cutting machine could very well determine their operational success.

When selecting a CNC laser cutting machine in 2023, there are several key features to consider that can significantly enhance your cutting experience and efficiency. First, pay attention to the laser power, as it determines the thickness of materials the machine can effectively cut. Machines with higher wattage can handle metal cutting and thicker materials, while lower-powered machines are ideal for delicate work with wood or acrylic.

Another critical aspect is the cutting speed and precision of the machine. Look for models that boast high-speed cutting capabilities coupled with accurate positioning systems, such as closed-loop control. This ensures that the laser can operate at peak performance without compromising on detail. Additionally, consider the compatibility with various materials and the ease of operation, including user-friendly software and the ability to integrate with existing workflows, which are essential for maximizing productivity and minimizing downtime.

This chart illustrates key features of the top 10 CNC laser cutting machines in 2023, comparing their cutting speed and maximum cutting thickness.

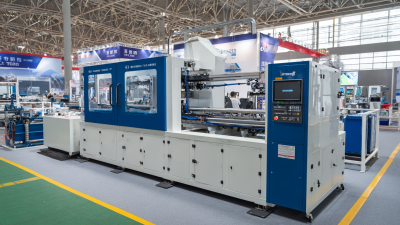

In 2023, the CNC laser cutting market is characterized by several top brands that are making significant strides in technology and innovation. These companies are at the forefront of providing high-powered laser cutting solutions that cater to a variety of industrial needs. The growth in the global CNC machine market, projected to reach approximately $195.6 billion by 2032, underscores the increasing demand for precision cutting technologies. As more industries adopt advanced laser cutting capabilities, key players are continuously enhancing their product offerings to meet the evolving requirements of their customers.

The landscape of laser cutting technology is also influenced by advancements in systems and methodologies. The latest statistics indicate that laser cutting machines are integral in shaping materials with high efficiency and precision, which is vital for sectors such as aerospace, automotive, and manufacturing. As brands invest in research and development, we can expect to see even more sophisticated machines that improve productivity and reduce operational costs, further solidifying their dominance in the market in the coming years.

As we dive into the world of CNC laser cutting machines, it is crucial to understand the market landscape and the features that set the best systems apart. The global CNC machine market is projected to expand from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, achieving a compound annual growth rate (CAGR) of 9.9%. This growth indicates a robust demand for precision engineering and versatile manufacturing solutions, making the selection of the right laser cutter an essential task for businesses aiming to stay competitive.

When considering the best CNC laser cutting machines, it's important to look for models that offer both high cutting quality and speed. Key factors to evaluate include power output, cutting area, and the type of materials each machine can handle. Additionally, features such as user-friendly interfaces and advanced software integration can significantly enhance operational efficiency.

**Tip:** When selecting a CNC laser cutter, ensure it has excellent customer support and maintenance services. This can save significant downtime in the operation phase.

Moreover, the assessment of hybrid technologies, such as the incorporation of AI in CNC applications, highlights the need for machines that not only meet production needs but are also adaptable to future advancements. Opting for machines with multi-axis capabilities may also provide greater flexibility in project execution.

**Tip:** Always review case studies or customer testimonials to gauge the real-world performance of CNC machines before making a purchase.

When choosing a CNC laser cutting machine, budget-friendly options can deliver high performance without breaking the bank. According to a recent industry report by Grand View Research, the global CNC laser cutting market is projected to reach $4.03 billion by 2025, which indicates a growing demand for cost-effective solutions in this sector.

These machines not only enhance precision in cutting but also reduce operational costs. For small businesses or hobbyists, investing in affordable models can provide a competitive edge in various applications, ranging from woodworking to metal fabrication.

When considering what to look for in budget-friendly CNC laser cutters, it’s important to prioritize key features such as cutting speed, material compatibility, and user interface. Many entry-level machines today come equipped with advanced software that allows users to easily design and execute projects. Investing in a cutter with a user-friendly interface can significantly decrease the learning curve, particularly for beginners.

Tips: Always check for warranties and customer support options when purchasing a budget CNC laser cutter. Additionally, read reviews from other users to gauge the reliability and performance of the machine. Upgrading components, like the laser tube, can also extend the life and enhance the capabilities of a more affordable model.

In 2023, the CNC laser cutting industry has seen substantial advancements in technology that significantly enhance efficiency and precision. Cutting-edge innovations, such as improved laser sources and integrated software systems, allow machines to operate faster and more accurately, reducing waste and optimizing production time. These advancements are not just about speed; they also enable the cutting of complex designs with intricate detailing that were previously difficult to achieve.

When choosing a CNC laser cutting machine, consider the power of the laser. Higher wattage can lead to faster cutting and the ability to work with thicker materials. Additionally, look for machines with advanced optics that focus the laser beam more effectively, delivering cleaner cuts and less post-processing work.

Another tip is to prioritize machines with robust software solutions that provide seamless integration with design programs. These systems enhance workflow efficiency by allowing for real-time monitoring and adjustments during the cutting process. Finally, ensure that the manufacturer offers strong customer support and regular software updates, as this can significantly enhance the longevity and performance of your CNC laser cutting investment.

| Model | Laser Type | Cutting Area (mm) | Power (W) | Max Speed (m/min) | Precision (mm) | Features |

|---|---|---|---|---|---|---|

| Model A | CO2 Laser | 1300 x 900 | 100 | 30 | 0.1 | Cutting and Engraving |

| Model B | Fiber Laser | 1500 x 3000 | 150 | 40 | 0.02 | High Speed Cutting |

| Model C | CO2 Laser | 1600 x 1000 | 120 | 25 | 0.1 | Foldable Design |

| Model D | Fiber Laser | 1300 x 2500 | 200 | 60 | 0.03 | Smart Control System |

| Model E | CO2 Laser | 1000 x 600 | 80 | 20 | 0.05 | Compact Size |

| Model F | Fiber Laser | 2000 x 3000 | 300 | 70 | 0.01 | User-friendly Interface |

| Model G | CO2 Laser | 3000 x 1500 | 250 | 50 | 0.1 | Versatile Cutting Options |

| Model H | Fiber Laser | 1200 x 850 | 100 | 35 | 0.02 | Low Maintenance |

| Model I | CO2 Laser | 1000 x 500 | 60 | 15 | 0.1 | Portable Solution |

| Model J | Fiber Laser | 2000 x 1000 | 500 | 80 | 0.01 | High Precision Engineering |