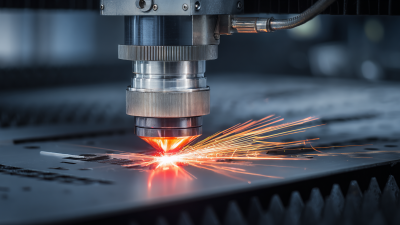

In today’s fast-paced manufacturing landscape, companies are constantly seeking innovative solutions to enhance their productivity and precision. Among the notable advancements, the Tube Laser Cutting Machine has emerged as a game-changer that brings unparalleled benefits to businesses across various industries. This technology not only allows for precise cutting of tubes and profiles but also streamlines production processes, making it an essential asset for modern manufacturing.

The versatility and efficiency of Tube Laser Cutting Machines enable businesses to tackle complex designs with ease, pushing the boundaries of what can be achieved in metal fabrication. As we delve into the top five benefits of incorporating this technology into your operations, it becomes clear how investing in a Tube Laser Cutting Machine can significantly impact operational efficiency, reduce material waste, and ultimately enhance the bottom line. In a competitive environment where precision and speed are paramount, embracing this cutting-edge technology is not just advantageous but essential for maintaining a competitive edge.

Tube laser cutting machines are revolutionizing precision engineering and manufacturing by enhancing product quality through unmatched accuracy and consistency. The precision offered by these machines allows manufacturers to create intricate designs that are often unattainable with traditional cutting methods. This heightened level of detail not only improves the aesthetic appeal of products but also contributes significantly to better functional performance, reducing the need for costly reworks and minimizing waste.

Tips: To maximize the benefits of tube laser cutting, ensure that your machine is regularly calibrated and maintained to guarantee optimal performance. Moreover, investing in staff training on the use of laser cutting technology can greatly improve operational efficiency and product quality.

Furthermore, advancements in tube cutting technology are enabling industries to adapt swiftly to market demands. This synergy with digital twin technology and artificial intelligence empowers manufacturers to optimize production processes, maintain quality control, and respond to customer requirements in real-time. By adopting these modern manufacturing techniques, businesses not only enhance their product offerings but also position themselves as leaders in their respective fields.

Tips: Consider integrating real-time data monitoring systems to track production quality and streamline operations. Collaborating with technology providers can also aid in customizing solutions tailored to specific manufacturing needs.

The integration of tube laser cutting machines into manufacturing processes revolutionizes efficiency, particularly in industries requiring precise and complex cuts. These machines significantly reduce the time taken for cutting operations, allowing businesses to streamline production workflows. By minimizing manual intervention and automating processes, tube laser cutting machines enhance operational speed and consistency, which is crucial in sectors like aerospace and medical device fabrication. Similar to the efficiency gains recently observed with electric benders in aerospace, tube lasers enable regular production of intricate geometries with minimal errors.

Moreover, tube laser cutting machines provide adaptability in handling various materials and shapes, which is vital for manufacturers facing growing demands for customization. The ability to execute different designs without extensive retooling saves both time and resources. As industries continue to embrace advanced technologies, such as robotics in rehabilitation and automated grinding systems, tube laser cutting stands out for its potential to dramatically enhance throughput and flexibility. By investing in these technologies, businesses can tackle the challenges of modern manufacturing with greater confidence, ensuring they stay competitive in an evolving market.

The cost-effectiveness of tube laser cutting machines is a significant advantage for businesses looking to streamline operations and maximize resources. According to a report by Research and Markets, the global laser cutting market is expected to reach $4.4 billion by 2026, driven largely by innovations that reduce material waste. Tube lasers allow businesses to achieve intricate cuts with high precision, resulting in less scrap material compared to traditional cutting methods. This precise cutting capability can reduce waste by up to 25%, leading to substantial cost savings over time.

Furthermore, the ability to handle a variety of materials and shapes makes tube laser cutting machines incredibly versatile. A study conducted by the Fabricators & Manufacturers Association (FMA) indicates that companies using tube laser technology can enhance their production efficiency by approximately 30%. This efficiency not only minimizes the cost associated with excess material but also reduces the overall energy consumption during the cutting process. Businesses that adopt tube lasers can not only meet the increasing demand for high-quality products but also do so in a more sustainable and economical manner, positioning themselves advantageously in a competitive market.

| Benefit | Description | Cost Savings (%) | Waste Reduction (%) | Production Time (Hours) |

|---|---|---|---|---|

| Increased Precision | Enhanced accuracy in cutting allows for complex shapes and finer details. | 15% | 20% | 3 |

| Faster Production | Significantly reduces overall machining time for projects. | 10% | 30% | 2 |

| Versatility | Able to cut various materials and thicknesses, suitable for diverse applications. | 5% | 15% | 2.5 |

| Labor Reduction | Less manual intervention reduces the need for skilled labor. | 20% | 10% | 1.5 |

| Sustainability | Reduced material waste contributes to a more sustainable manufacturing process. | 25% | 50% | 3.5 |

Tube laser cutting machines have become increasingly vital across various industries due to their versatility and precision. In sectors such as automotive, aerospace, and construction, these machines allow for the efficient processing of complex shapes and designs in metal tubing and piping. For instance, the automotive industry utilizes tube laser cutting for creating lightweight structures that enhance fuel efficiency without compromising strength. This capability is especially important in today's push for greener technologies and less environmental impact.

Additionally, tube laser cutting is making significant strides in the furniture and decor industries. Designers leverage this technology to craft intricate designs out of tubular metals, offering unique aesthetics while maintaining functionality. From bespoke furniture frames to artistic installations, the adaptability of laser cutting machines opens up a world of creative possibilities. Industries focused on manufacturing medical equipment also benefit greatly from tube laser cutting, as precision is paramount when producing components that meet stringent safety standards. The range of applications illustrates how tube laser cutting technology elevates not only production efficiency but also innovative design across various fields.

The introduction of tube laser cutting technology has revolutionized the manufacturing sector, particularly in terms of design innovation. This cutting-edge method allows for complex shapes and intricate designs that traditional cutting methods cannot achieve. According to a report by Technavio, the global laser cutting market is expected to grow by over $2 billion between 2021 and 2025, underscoring the increasing reliance on laser technology for enhancing production capabilities.

One significant advantage of tube laser cutting is its ability to minimize material waste, with reports indicating that businesses can reduce material costs by up to 30% compared to traditional cutting. This efficiency not only promotes sustainability but also enables manufacturers to explore more complex and creative designs without the fear of significant cost increases. Furthermore, the precision offered by tube laser cutting allows for tighter tolerances, resulting in higher quality finished products that meet the exact specifications needed for various applications in industries such as automotive, aerospace, and architecture. Overall, the capability to innovate relentlessly due to the flexibility of tube laser cutting opens new avenues for creative manufacturing.

The chart displays the top 5 benefits of using tube laser cutting machines rated out of 10. These benefits highlight the crucial advantages businesses can achieve through innovation in design and manufacturing processes.