In today's fast-paced manufacturing landscape, the implementation of advanced technologies is crucial for staying competitive. One such revolutionary tool is the Laser Cutting Machine, which has transformed the way businesses operate across various industries. As industry expert Dr. Jane Harper notes, "The precision and versatility of laser cutting technology not only enhance production efficiency but also open new avenues for creativity and design." With this technology at their disposal, companies can streamline processes, reduce costs, and improve product quality.

The top 10 benefits of using a Laser Cutting Machine illustrate the significant impact it can have on operational success. From intricate designs to high-speed performance, the advantages are extensive and can lead to substantial business growth. The integration of this cutting-edge machine can lead to improved accuracy and reduced material waste, allowing businesses to not only save time but also contribute to sustainable practices. As industries continue to evolve, harnessing the capabilities of a Laser Cutting Machine is becoming increasingly essential for those looking to maintain a competitive edge.

Laser cutting machines have revolutionized the manufacturing landscape, primarily due to their unmatched precision and accuracy. The technology employs focused laser beams to cut materials with extreme fineness, allowing manufacturers to achieve intricate designs and tight tolerances that traditional cutting methods simply cannot match. This precision minimizes waste, ensuring that every cut is purposeful and efficient, which can significantly enhance the production process.

Moreover, the ability to adjust the laser settings according to the specific material being cut allows for exceptional versatility. Whether working with wood, metal, or plastics, laser cutting ensures that edges remain clean and finished without the need for additional processing. This accuracy not only reduces the possibility of errors but also improves the overall quality of the final product. By consistently delivering precise cuts, businesses can boost their reputation for reliability and craftsmanship, ultimately leading to higher customer satisfaction and repeat business.

| Benefit | Description | Impact on Business |

|---|---|---|

| Precision Cutting | Laser cutting offers high precision, allowing for intricate designs without compromising quality. | Improved product quality and design flexibility. |

| Material Versatility | Can cut through various materials such as metal, wood, plastic, and fabric. | Wider range of products and applications. |

| Reduced Waste | Laser cutting minimizes material waste compared to traditional cutting methods. | Cost savings on materials and improved profitability. |

| Speed | Fast cutting speeds lead to quicker turnaround times. | Increased efficiency and productivity. |

| Automated Processes | Integration with CAD/CAM software allows for streamlined design and production. | Enhanced workflow and reduced human error. |

| Minimal Heat Affected Zone | Laser cutting produces a much smaller heat affected zone than traditional methods. | Maintains material integrity and reduces the risk of warping. |

| Repeatability | Laser cutting can achieve the same results consistently with high accuracy. | Reliable production of components. |

| Complex Shapes | Ability to cut complex shapes and detailed designs that are difficult with other methods. | Differentiation in product offerings. |

| Lower Labor Costs | Requires less manual labor compared to traditional cutting methods. | Reduced overhead costs and operational efficiency. |

| Safety Features | Modern laser cutting machines include advanced safety features to protect operators. | Improved workplace safety and compliance. |

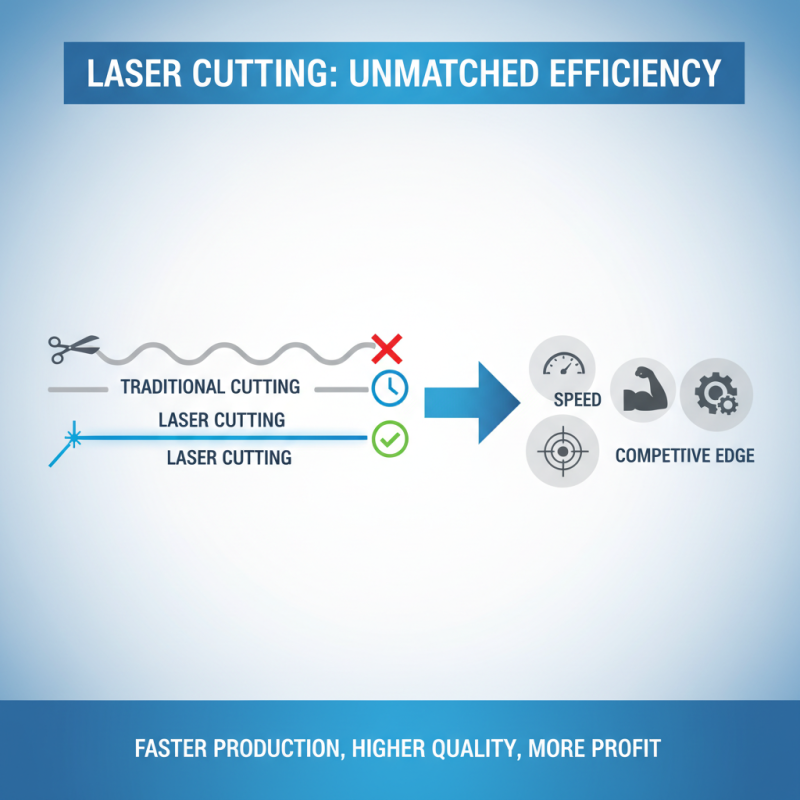

When it comes to optimizing production efficiency, laser cutting machines are unparalleled in their speed and precision. One of the critical advantages of incorporating a laser cutting system into business operations is the dramatic reduction in production time. Unlike traditional cutting methods, laser technology offers rapid processing, enabling businesses to complete tasks much quicker without sacrificing quality. This enhanced speed allows manufacturers to meet tight deadlines and respond swiftly to market demands, ultimately giving them a competitive edge.

Moreover, the automated capabilities of laser cutting machines further augment time efficiency. With minimal manual intervention required, businesses can streamline their workflows significantly. The machines can run continuously, cutting intricate designs with perfect accuracy, which reduces the necessity for extensive post-processing. This not only accelerates production times but also minimizes the potential for human error. As a result, companies can redirect those saved hours towards other critical aspects of their operations, leading to increased productivity and profitability.

Laser cutting technology has revolutionized the manufacturing and design landscapes across various industries, providing unparalleled versatility. Its precision and efficiency are sought after in sectors like automotive, aerospace, and textiles. For example, in the automotive industry, laser cutting is used for creating intricate parts and components with minimal waste, which enhances production efficiency and reduces costs. Similarly, the aerospace sector benefits from the lightweight designs achievable through laser cutting, allowing for innovative engineering without compromising safety.

In addition to traditional manufacturing, laser cutting finds applications in creative arts and crafts, jewelry making, and even construction. Artists utilize laser-cutting machines to create intricate designs and patterns in wood, acrylic, and metal, allowing for a level of detail that would be difficult to achieve with traditional methods. In construction, precise laser-cut components can improve both the aesthetics and the structural integrity of buildings.

Tip: When considering a laser cutting machine, think about the materials you'll primarily work with. Different machines are optimized for various materials, so selecting the right one can enhance efficiency and output quality.

Tip: Regular maintenance of your laser cutting machine is crucial. Keeping the optics clean and ensuring proper alignment will not only prolong the machine's lifespan but also maintain cutting accuracy and reduce production downtime.

Laser cutting technology has revolutionized manufacturing by significantly reducing material waste, making it an indispensable tool for businesses looking to enhance cost-effectiveness. According to a report by P&S Intelligence, laser cutting machines can achieve a material utilization rate of up to 90%, compared to traditional cutting methods which often result in over 30% waste. This higher efficiency not only leads to substantial savings on material costs but also aligns with sustainability goals, allowing companies to lessen their environmental footprint.

Moreover, the precision offered by laser cutting minimizes the need for rework and scrap, which further contributes to cost savings. Studies have indicated that businesses employing laser cutting technology can reduce their overall production costs by as much as 20%. This reduction is achieved through optimized cutting paths and the ability to handle complex geometries without sacrificing speed or accuracy. In an industry where margins are tight, the ability to lower costs while improving quality can provide a significant competitive advantage.

As companies increasingly prioritize efficiency and sustainability, the adoption of laser technology is emerging as a key strategy for modern manufacturing businesses.

Laser cutting machines have revolutionized the way businesses approach design and manufacturing. One of the primary benefits is their ability to create intricate and complex cuttings with unparalleled precision. This allows designers to realize their creative visions without the constraints that traditional cutting methods impose. Whether it’s detailed patterns in wood, intricate designs in metal, or customized pieces in acrylic, laser technology makes it possible to execute complex designs that were once thought to be impractical or too costly.

For businesses looking to enhance their design capabilities, it’s essential to understand the potential of laser cutting. One key tip is to invest time in software training to maximize the use of design tools compatible with laser cutting technology. Familiarity with CAD software can bring a significant advantage, enabling designers to create detailed blueprints that translate perfectly into finished products. Additionally, experimenting with different materials can help discover the full potential of laser cutting, as varying thicknesses and compositions react differently to laser processes.

Another important consideration is optimizing your workflow for laser cutting projects. Planning the layout of cuts to maximize material usage not only saves costs but also allows for more intricate designs without overloading the machine. It's advisable to conduct test runs on new designs or materials to fine-tune machine settings, ensuring the final output meets quality standards without wasted resources. Embracing these strategies can significantly boost a business's capabilities in design and production.