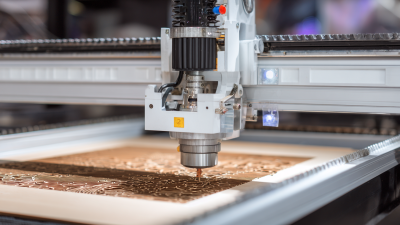

In the world of modern manufacturing, the Iron Laser Cutting Machine stands out as a revolutionary tool. It enhances precision and efficiency in cutting various metals. This advanced technology yields optimal results with minimal waste, ensuring cost-effectiveness for businesses of all sizes.

Employing an Iron Laser Cutting Machine can dramatically improve production speed. It offers high-quality cuts with intricate designs. However, there are aspects to consider. Not every machine suits every application. Understanding the specific needs of your project helps in making the right choice.

Moreover, training staff on this equipment is crucial. A skilled operator can unlock the full potential of the Iron Laser Cutting Machine. Nonetheless, initial setup costs can be daunting for small enterprises. Balancing investment with long-term benefits prompts thoughtful decision-making. Overall, the Iron Laser Cutting Machine offers incredible potential, yet careful planning is essential.

The precision of iron laser cutting technology offers numerous advantages. It delivers clean, accurate cuts that minimize material wastage. This efficiency makes it ideal for intricate designs. For industries needing high-quality components, precision is crucial. A slight error can lead to significant issues. Hence, investing in a reliable iron laser cutting machine is essential.

Tip: Always monitor machine calibration. Small adjustments can improve accuracy. Regular checks can prevent larger problems down the line.

Laser cutting technology also enhances design flexibility. Designers can experiment without being limited by traditional cutting methods. The ability to create complex shapes with high precision opens new creative avenues. However, it's vital to acknowledge that not every project may require such intricacy.

Tip: Assess project needs carefully. Sometimes, simpler methods can yield satisfactory results. Balancing quality with cost is key.

Ultimately, iron laser cutting machines represent a leap forward in manufacturing. These devices transform how industries approach fabrication. However, a thorough understanding of capabilities and limitations is necessary to fully leverage this technology.

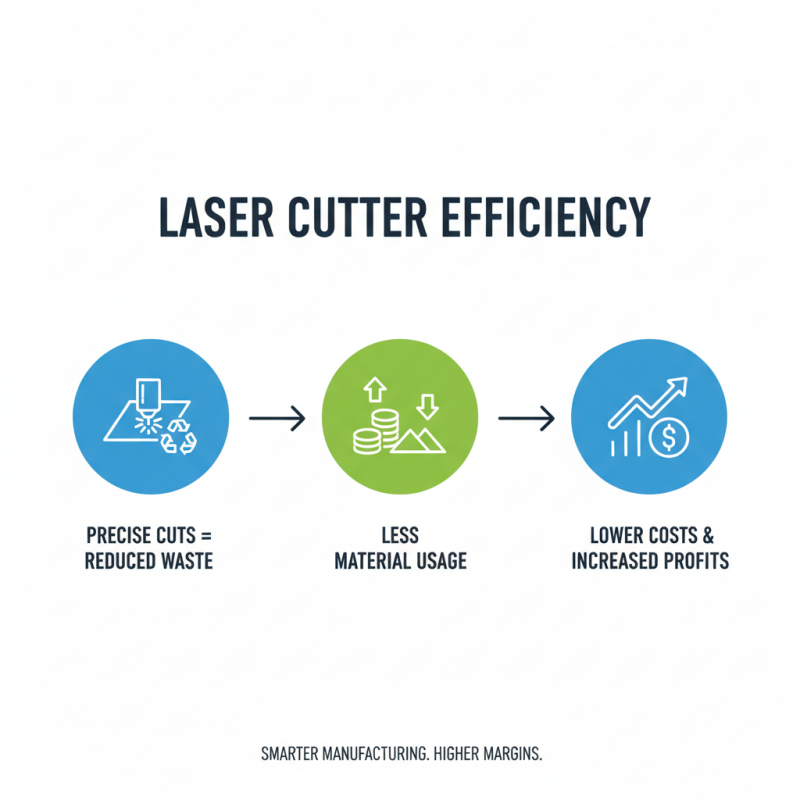

The cost efficiency of manufacturing processes using laser cutters is striking. These machines significantly reduce material waste, as they provide precise cuts. This means fewer raw materials are needed for each project. For businesses, this translates to lower costs and increased profit margins.

Moreover, laser cutting machines can work faster than traditional methods. This speed allows for higher production rates. Higher output means companies can meet client demands more effectively. Investing in a laser cutter can lead to quicker project turnaround times. However, the initial investment can be daunting for some small businesses.

In some cases, operators may require specialized training. This is an added cost that could offset some of the savings. Companies must weigh these factors carefully. Long-term benefits often outweigh the initial challenges, but short-term discomfort can be real. Balancing cost efficiency with operational effectiveness remains a key consideration for manufacturers.

Iron laser cutting machines offer significant safety enhancements for operators. These machines are designed with advanced safety features that aim to minimize accidents. Enclosed work areas keep operators at a safe distance from cutting processes. Automatic shut-off systems activate when maintenance is required, reducing the risk of injury.

In addition, many models include advanced sensors. These sensors detect potential hazards and react swiftly. For example, if an object enters the cutting area unexpectedly, the machine halts. However, the effectiveness of these features depends on proper user training. Operators must understand how to utilize safety measures effectively.

While the integrated safety features are beneficial, human error remains a concern. Unattended operation can lead to issues. Safety mechanisms function best with mindful operators. Regular inspections of safety systems are essential to ensure they work correctly. Relying solely on technology can be a mistake. Hence, a balanced approach is crucial for enhanced workplace safety.

Laser cutting technology is transforming industries with its versatility. From automotive to aerospace, it finds applications in various sectors. Iron laser cutting machines offer precision and flexibility that other methods lack. They can handle complex designs while maintaining high accuracy. This adaptability allows manufacturers to produce unique parts efficiently.

In the signage industry, laser cutting delivers intricate designs. It can create custom shapes for different branding needs. The process is quick, reducing time-to-market for new products. However, some operators may struggle with software integration. Continuous training is vital to maximize the machine's potential.

Tips for laser cutting success include regular maintenance. This keeps machines running smoothly and enhances performance. Understanding material properties is also crucial. Different materials react uniquely to laser cutting. Experimentation might lead to better results. Don't shy away from making mistakes; each one is a learning opportunity. Embrace the technology and explore its vast possibilities.

Laser cutting technology has transformed the manufacturing sector, offering significant environmental benefits. This method reduces material waste compared to traditional cutting techniques. It allows for precise cuts, ensuring that nearly all of the material is used efficiently. Less waste translates to a smaller carbon footprint. This is vital as industries strive to meet sustainability goals.

Moreover, laser cutting machines use less energy overall. They can operate with greater efficiency, consuming less power during the cutting process. This means reduced greenhouse gas emissions. Many businesses find that adopting laser technology not only helps the environment but also lowers operating costs.

However, the initial investment in laser cutting machines can be substantial. Smaller companies may hesitate to make such a commitment. Additionally, maintaining these machines requires a skilled workforce. Training employees can take time and resources. These challenges should be weighed against the environmental benefits and potential long-term savings. Embracing this technology can lead to a greener future, but it is important to address these hurdles.

| Benefit | Description | Environmental Impact |

|---|---|---|

| Precision Cutting | Achieves high accuracy in cuts, reducing waste. | Less material waste contributes to lower environmental footprint. |

| Minimal Heat Affected Zone | Produces less thermal distortion compared to traditional methods. | Reduces energy consumption in post-processing. |

| Reduced Material Waste | Maximizes the use of raw materials. | Supports sustainable manufacturing practices. |

| Lower Energy Consumption | More efficient than many traditional cutting methods. | Decreases overall carbon footprint. |

| Enhanced Safety | Laser cutting reduces contact hazards during fabrication. | Promotes safer working environments, leading to less risk of accidents. |

| Versatile Material Cutting | Can cut a wide range of materials from metals to plastics. | Encourages recycling and repurposing of materials. |

| Automated Processes | Automation leads to reduced labor and efficiency. | Less energy used for labor-intensive processes. |

| Less Noise Pollution | Laser cutting is quieter compared to conventional methods. | Reduced noise levels improve workplace conditions. |

| Greater Design Flexibility | Facilitates complex designs that are hard to achieve with other methods. | Promotes innovative products which can be eco-friendly. |

| Reduced Toxic Emissions | Produces fewer emissions during the cutting process. | Improves air quality in manufacturing environments. |