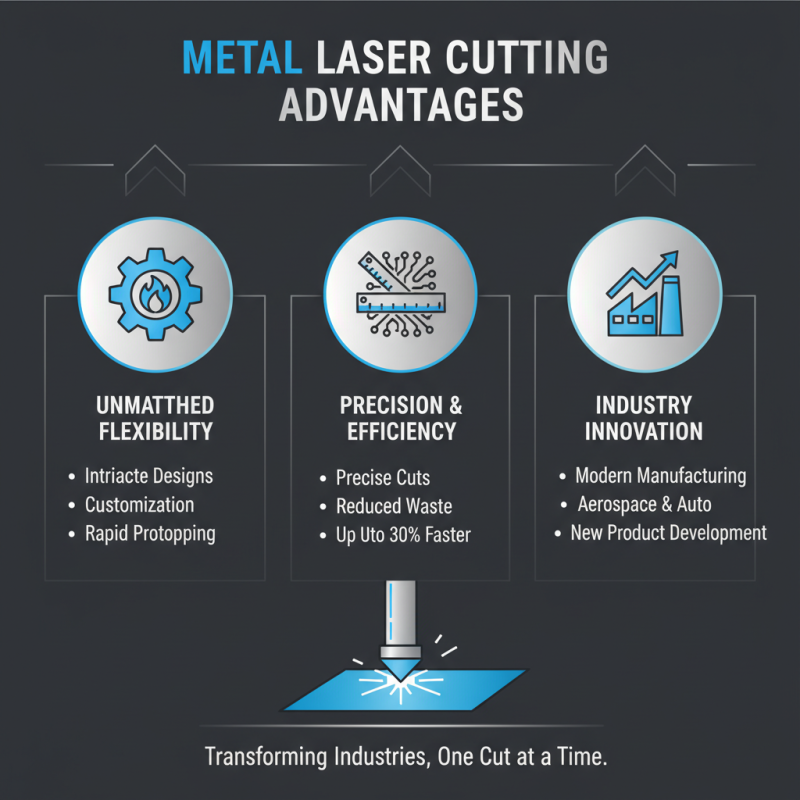

In today's fast-paced manufacturing landscape, Metal Laser Cutting has emerged as a game changer for various industries. According to a report by Research and Markets, the global laser cutting equipment market is expected to grow at a CAGR of 6.8% from 2021 to 2026. This growth reflects the increasing demand for precision and efficiency in production processes.

Metal Laser Cutting technology offers remarkable benefits, including reduced waste and improved design flexibility. Companies can achieve intricate designs that were once impossible with traditional methods. A study by MarketsandMarkets highlights that around 40% of manufacturers have adopted laser cutting for its speed and accuracy. However, not all industries have embraced this technology, which raises questions about potential barriers and the need for broader understanding.

While Metal Laser Cutting is revolutionizing manufacturing, there are challenges. Not all facilities are equipped to handle laser systems efficiently. There’s an underlying need for training and maintenance, which can involve significant resources. As industries continue adapting, it’s crucial to address these gaps and ensure that Metal Laser Cutting can reach its full potential across all sectors.

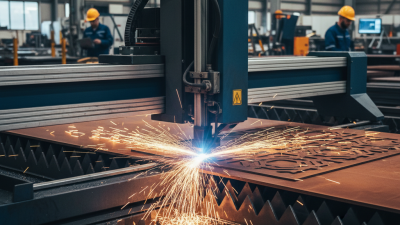

Metal laser cutting has gained immense popularity in modern industries, thanks to its precision and accuracy. With laser technology, manufacturers can achieve intricate designs that traditional cutting methods struggle to match. The process allows for minimal material waste, which is a significant advantage for sustainability. Even within the same cut, variations in speed can yield different degrees of precision. This means that consistency can sometimes be an elusive goal.

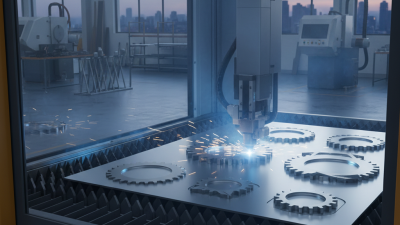

The accuracy of metal laser cutting offers remarkable benefits. Components can be crafted to tight tolerances, reducing the need for further adjustments. Yet, achieving this level of precision requires constant monitoring and maintenance of the machinery. Operators must be skilled, ensuring that every parameter is dialed in perfectly. Any slight miscalculation can lead to flawed products, emphasizing the need for rigorous checks.

Moreover, precision does not come without its challenges. It demands significant investment in both technology and training. As industries adopt this cutting method, the learning curve may slow down production initially. Businesses must remain adaptable, carefully evaluating projects to optimize efficiency while maintaining quality. Precision brings advantages but also the necessity for ongoing improvement and reflection on processes.

Metal laser cutting technology is transforming modern industries. One of its most significant benefits is the reduction of material waste. Traditional cutting methods often result in excessive scrap. However, laser cutting allows for precise cuts, minimizing waste. According to a 2021 industry report, laser cutting can reduce material waste by up to 30%. This efficiency directly impacts the bottom line for manufacturers.

The accuracy of laser cutting ensures that every square inch of material is utilized effectively. For example, intricate designs that would be difficult to achieve with other methods can be easily cut using lasers. This capability not only lowers waste but also enhances overall production efficiency.

However, not all companies utilize laser cutting technology. Some may be hesitant due to the initial investment costs or the need for specialized training. As a result, they continue to produce more waste, reflecting a missed opportunity for improving sustainability.

Incorporating laser cutting into manufacturing processes can lead to smarter resource management. It encourages companies to rethink their materials usage. While the upfront costs may seem daunting, the long-term savings and environmental benefits are undeniable. Companies must balance the immediate financial impact with the bigger picture of sustainability and efficiency. Embracing this technology could be a turning point for many industries.

Metal laser cutting provides unmatched flexibility in design and customization, significantly benefiting various modern industries. Traditional cutting methods often limit creativity. However, laser systems allow for intricate designs and precise cuts. Reports indicate that industries utilizing laser cutting have increased efficiency by up to 30%. This technology accommodates rapid prototyping, enabling businesses to bring concepts to life quickly.

Customization options are virtually endless. With laser cutting, unique shapes and patterns can be produced without extensive retooling. This capability reduces waste and conserves materials. A study from a leading manufacturing group showed that precise cutting can decrease material waste by 20-25%. While this technology offers substantial benefits, some companies struggle to adapt. Implementing laser cutting systems requires a steep learning curve. Employees may need extensive training to optimize these advanced machines.

Additionally, the initial investment for laser cutting technology can be high. Smaller businesses might hesitate to adopt it due to financial constraints. They must weigh the potential long-term savings against startup costs. While laser cutting stands out for design flexibility, not all industries can easily transition. Ongoing assessments and adjustments are crucial for realizing its full potential.

Metal laser cutting has revolutionized the manufacturing sector, significantly enhancing production speed and efficiency. According to a report by MarketsandMarkets, the laser cutting market is projected to reach $6.7 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.6%. This growth indicates that industries are increasingly embracing laser technology for faster turnaround times.

Laser cutting offers precision that traditional methods struggle to match. With tolerances often within ±0.1 mm, manufacturers can reduce material wastage. This precision leads to fewer reworks and lowers costs. Companies report that metal laser cutting can improve production speed by up to 30%. This is particularly beneficial in high-demand sectors like aerospace and automotive. However, the initial investment in laser equipment can be substantial, posing challenges for smaller businesses.

Despite these benefits, there are considerations for manufacturers. As they adopt new technologies, some face a learning curve. Employees must be trained adequately for optimal machine use. Furthermore, the equipment requires regular maintenance. Neglecting this can lead to downtime, countering the efficiency gained. Balancing up-front costs with long-term benefits remains a topic of ongoing debate in the industry.

Metal laser cutting has transformed modern industries. It offers cost-effectiveness by reducing material waste and labor costs. The precision of laser cutting minimizes errors, leading to less rework. Automation enhances efficiency, allowing for faster production cycles. This technology provides great flexibility in design, accommodating intricate shapes and designs that were once challenging.

Long-term benefits include lower operational costs. Companies can invest savings back into their processes. Maintenance is generally lower with laser cutting systems. The durability of laser-cut components can improve product lifespan. However, there are challenges to consider. Initial setup costs can be high. Companies must invest in training to fully utilize this technology. It's essential to weigh these factors when adopting metal laser cutting solutions.

| Benefit | Description | Cost-Effectiveness | Long-Term Benefits |

|---|---|---|---|

| Precision Cutting | High accuracy in cutting complex shapes and designs. | Reduces material waste. | Improves product quality. |

| Speed | Faster cutting speeds compared to traditional methods. | Increases production efficiency. | Reduces lead times for projects. |

| Flexibility | Can cut a wide range of materials and thicknesses. | Adapts easily to different production requirements. | Supports various product designs. |

| Reduced Maintenance | Lower wear and tear on cutting equipment. | Decreases maintenance costs. | Enhances equipment lifespan. |

| Safety | Less physical handling of materials required. | Reduces workplace accidents. | Promotes a safer work environment. |

| Automation | Easily integrated with automated systems. | Lowers labor costs. | Enhances consistency and reduces errors. |

| Environmentally Friendly | Less energy consumption compared to other methods. | Decreases carbon footprint. | Supports sustainable practices. |

| Material Saving | Minimal kerf and reduced scrap generation. | Direct impact on raw material costs. | Improves overall profitability. |

| Design Capabilities | Allows for intricate designs not possible with traditional cutting. | Can lead to innovative product development. | Enhances competitive edge. |

| Quality Control | Provides consistent cut quality with minimal variance. | Reduces costs associated with defects. | Enhances brand reputation. |