In 2023, the manufacturing industry continues to evolve with advanced technologies that enhance efficiency and productivity. Among these innovations, Pipe Laser Cutting has emerged as a front-runner, offering unparalleled precision and speed while maintaining cost efficiency. According to a recent report by the International Journal of Advanced Manufacturing Technology, Pipe Laser Cutting can increase production speeds by up to 30% compared to traditional cutting methods, making it an invaluable asset for modern fabrication operations.

Industry expert Dr. Emily Chen, a leading researcher in laser technology, emphasizes, "The integration of Pipe Laser Cutting in manufacturing not only reduces material waste but also significantly enhances the accuracy of cuts, providing manufacturers with a competitive edge." The growing adoption of this technology has allowed companies to streamline their processes and reduce operational costs, highlighting the necessity of embracing these advancements in a rapidly evolving market.

As businesses seek to optimize their operations, understanding the advantages of Pipe Laser Cutting becomes paramount. By leveraging this modern cutting technique, companies can ensure they remain competitive, driving growth while consistently meeting quality and precision standards. The top five advantages of Pipe Laser Cutting—precision, speed, and cost efficiency—underscore its role as a transformative technology in the manufacturing landscape.

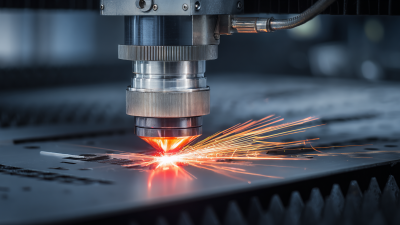

Pipe laser cutting is rapidly becoming a preferred method in modern manufacturing due to its numerous benefits. One of the primary advantages is precision. Laser cutting technology allows for intricate designs and precise dimensions, which are crucial in industries requiring high-quality outputs, such as aerospace and automotive manufacturing.

This level of accuracy minimizes material waste and reduces the need for extensive post-processing, leading to a more streamlined production process.

In addition to precision, speed is another significant benefit of pipe laser cutting. Compared to traditional cutting methods, laser systems can operate at higher speeds, allowing for faster turnaround times on projects. This efficiency not only meets tight deadlines but also enhances overall productivity.

Furthermore, cost efficiency is a key consideration in manufacturing. By reducing scrap material and speeding up production cycles, pipe laser cutting helps businesses lower operational costs.

As manufacturers continue to seek ways to improve their processes, the integration of pipe laser cutting technologies positions them to thrive in an increasingly competitive landscape.

The enhancement of precision in manufacturing through advanced laser technology is a game changer for various industries. In 2023, pipe laser cutting technology has emerged as a leading solution, offering unmatched precision that traditional cutting methods struggle to achieve. This advancement stems from innovative laser systems that focus on fine-tuning the cutting process, allowing for intricate designs and optimal material usage. The ability to create precise cuts reduces waste and enhances the overall quality of finished products, making laser cutting an essential component in modern fabrication.

As laser technology continues to evolve, the introduction of femtosecond laser systems is revolutionizing precision manufacturing. These lasers operate on an incredibly short timescale, enabling unprecedented accuracy in machining at the microscopic level. This technique is particularly beneficial in sectors such as electronics, where the demand for miniaturization of components is relentless. The growth of the laser cladding services market, projected to expand substantially by 2033, highlights the increasing reliance on advanced laser applications. Such innovations not only streamline production processes but also significantly cut operational costs, delivering a competitive edge for businesses that adopt these technologies.

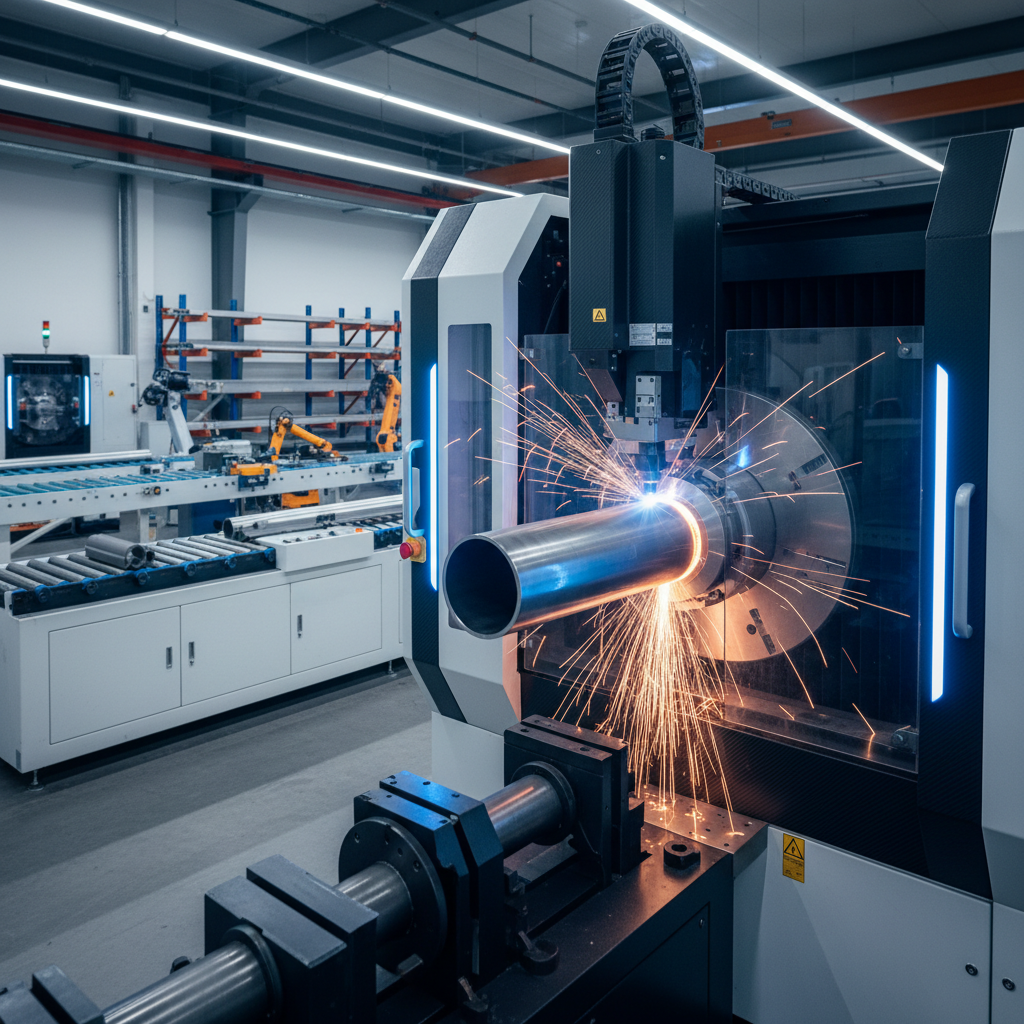

In the fast-paced world of manufacturing, increasing production speed is critical for staying competitive, and pipe laser systems offer a powerful solution. These advanced systems are designed to streamline the cutting process, allowing for rapid, precise cuts that significantly reduce downtime. With the ability to handle various materials and thicknesses, pipe laser cutting machines enable manufacturers to meet tight deadlines without sacrificing quality or accuracy.

Moreover, the integration of automated features in pipe laser systems enhances efficiency. Operators can set up jobs with minimal manual intervention, leading to quicker turnaround times. The high-speed cutting capabilities not only improve workflow but also optimize resource utilization, allowing companies to achieve higher output levels. As industry demands continue to rise, adopting pipe laser technology can give businesses the edge they need to thrive in an ever-evolving market.

In recent years, the cost efficiency of pipe laser cutting compared to traditional methods has garnered significant attention in the manufacturing industry. According to a 2022 report by Tecnomen Research, companies utilizing pipe laser cutting technology have seen a reduction in material waste by up to 30%. This notable decrease not only directly contributes to lower material costs but also enhances overall sustainability by minimizing scrap. Additionally, with advancements in laser cutting technology, the operational costs have decreased significantly, highlighted by a 25% reduction in labor expenses, as reported by the Laser Institute of America (LIA).

Furthermore, pipe laser cutting allows for faster production times, which translates into higher throughput and increased profitability. Industrial Laser Solutions indicates that the setup time for laser cutting is approximately 50% less than that for traditional cutting methods, allowing manufacturers to respond swiftly to market demands. The upfront investment in laser cutting machinery may be higher; however, the return on investment is typically observed within 12-18 months due to these efficiencies. As industries seek to streamline operations and maintain competitive pricing, pipe laser cutting stands out as a formidable alternative, paving the way for both cost savings and improved operational efficiency in 2023.

Pipe laser cutting technology has rapidly gained prominence across various industries, primarily due to its remarkable versatility. In sectors such as construction, automotive, and aerospace, the ability to handle different pipe materials and shapes with precision has transformed manufacturing processes. This cutting technique accommodates a wide range of diameters and thicknesses, making it ideal for producing customized components tailored to specific project requirements.

Furthermore, the adaptability of pipe laser cutting expands its applications beyond traditional manufacturing. In the energy sector, for instance, it is used for creating intricate designs in pipelines that must withstand extreme conditions. The food and beverage industry also benefits from this technology, where sanitation and precision are crucial. As companies seek to enhance efficiency while minimizing waste, the versatile nature of pipe laser cutting positions it as a critical asset in achieving operational excellence across varied fields.

| Advantage | Description | Industries Benefiting | Estimated Cost Savings (%) |

|---|---|---|---|

| Precision | High accuracy in cutting complex shapes, allowing for tight tolerances. | Manufacturing, Aerospace, Automotive | 25% |

| Speed | Faster cutting processes compared to traditional methods, improving throughput. | Construction, Metal Fabrication | 30% |

| Cost Efficiency | Reduction in material waste, lower operating costs. | Energy, Oil & Gas | 20% |

| Versatility | Applicable to various materials including metal, plastic, and composites. | Textiles, Electronics | 15% |

| Reduced Setup Time | Minimal tool changes required, quick setup for various cutting tasks. | General Manufacturing, Prototyping | 10% |